Surface polishing treatment system for gray cast iron surface plate

A cast iron platform and surface polishing technology, applied in surface polishing machine tools, grinding/polishing equipment, grinders, etc., can solve the problems of cast iron platform damage, rust, affecting work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

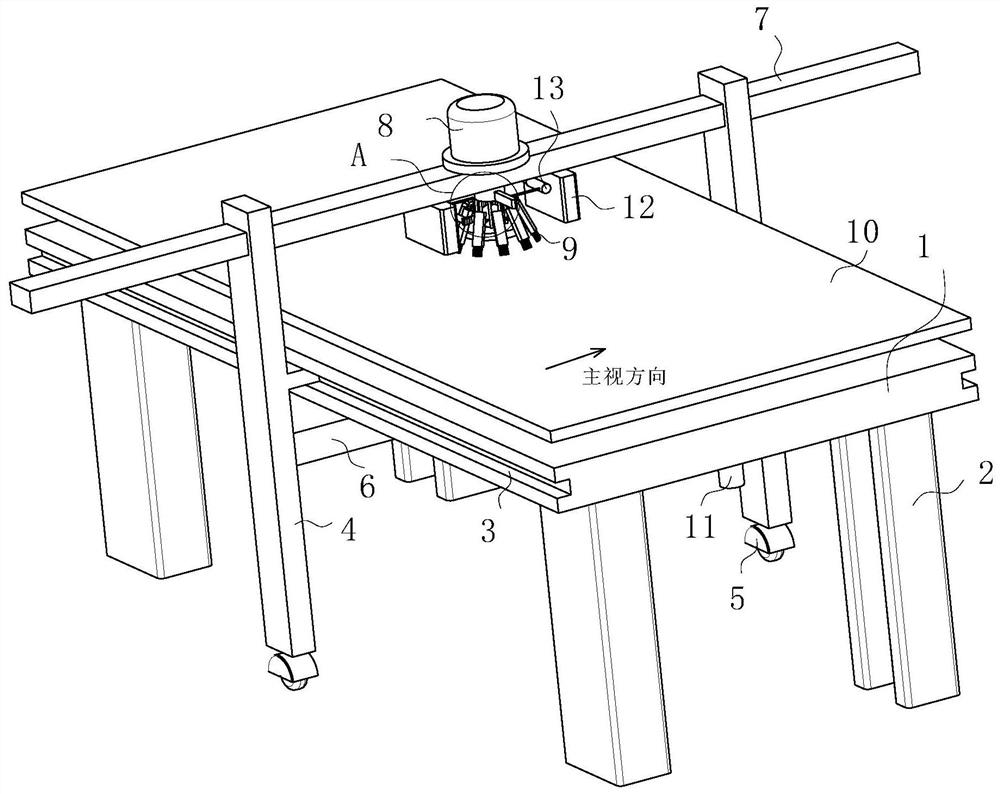

[0019] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the following describes the present invention in conjunction with specific implementations. The front, back, left, right, top, and bottom of the present invention are all based on figure 1 The direction of the main view.

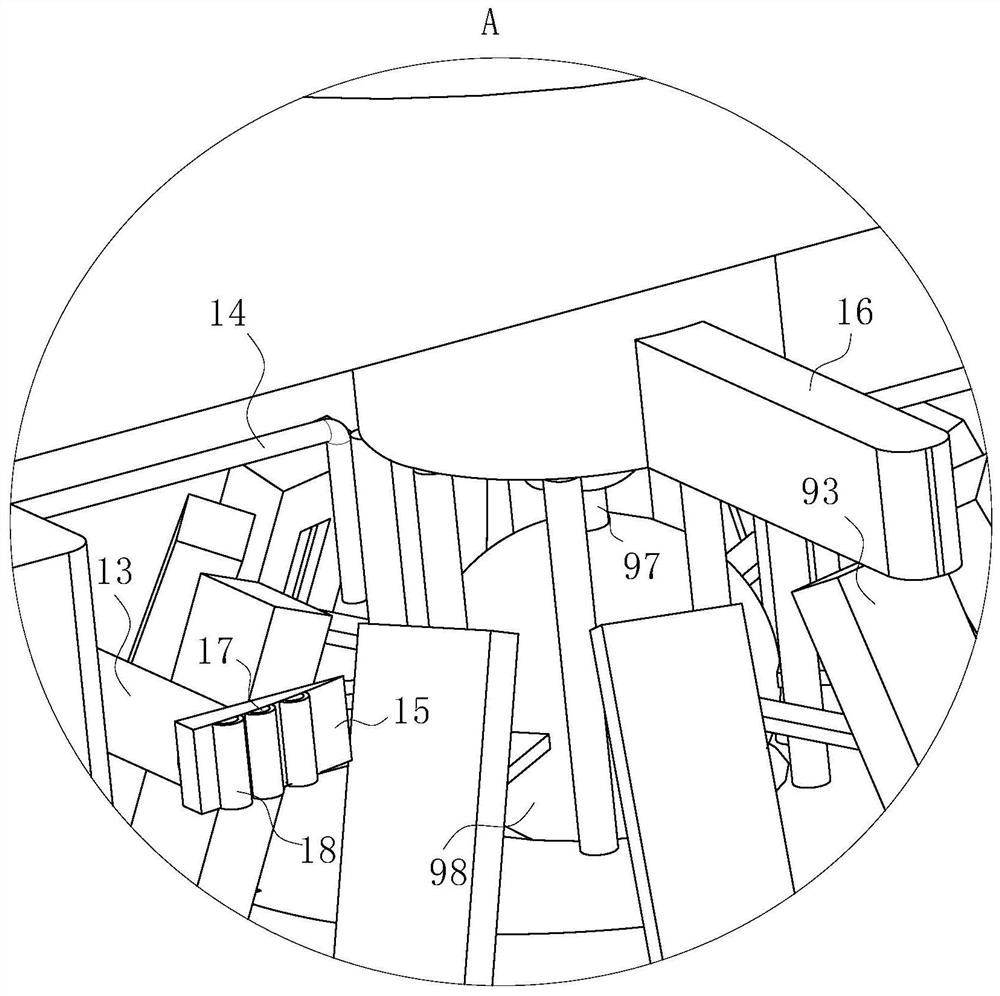

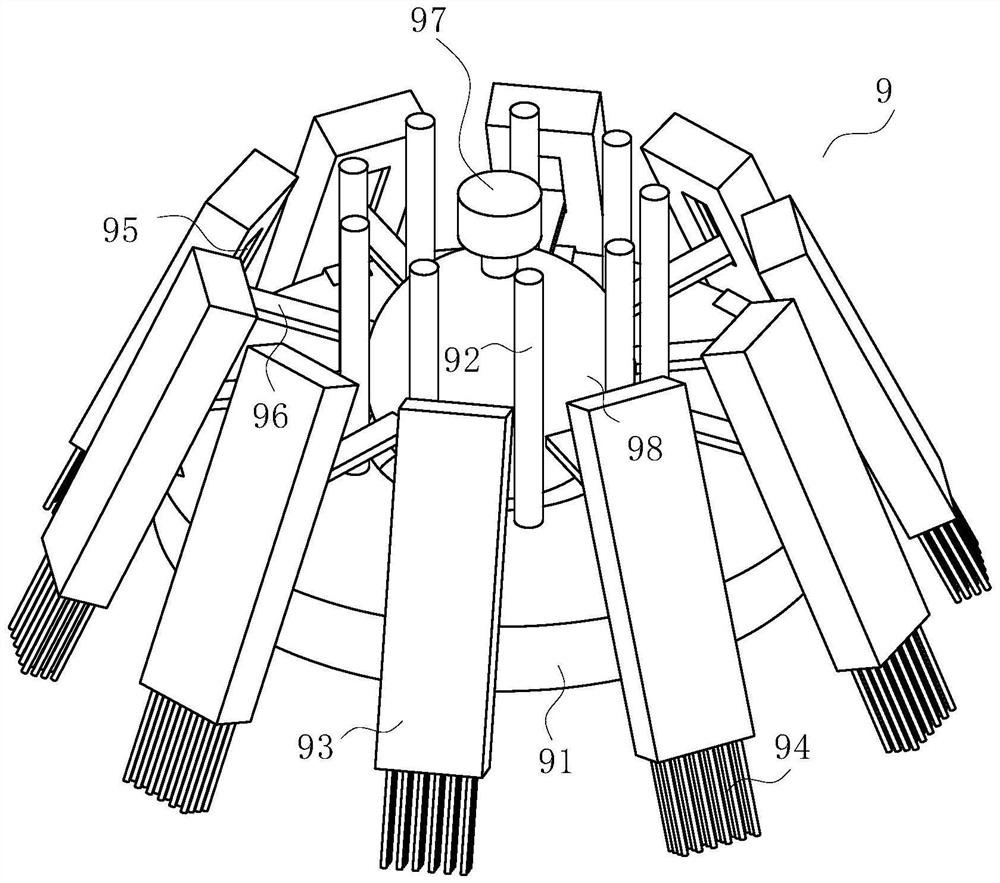

[0020] Such as Figure 1-3 As shown, the surface polishing treatment system of a gray cast iron platform according to the present invention includes a workbench 1 and a leg 2 installed at the bottom of the workbench. A card holder 4 is provided on the slot 3, and a drive wheel 5 is installed at the bottom of the card holder 4; the two holders 4 are fixedly connected to the same cross bar 6 at a position close to the bottom surface of the workbench 1. The two holders 4 The same beam 7 is inserted near the top, the beam 7 is provided with a motor 8, and the output end of the motor 8 is provided with a polishing device 9, the polishin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com