Production method of super-hydrophobic, moisture-resistant and scaling-resistant hybrid nanofiber composite membrane for membrane distillation

A technology of nanofibers and production methods, applied in the field of preparation of superhydrophobic hybrid nanofiber composite membranes, which can solve problems such as easy scaling, difficult long-term operation, easy wetting of separation membranes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

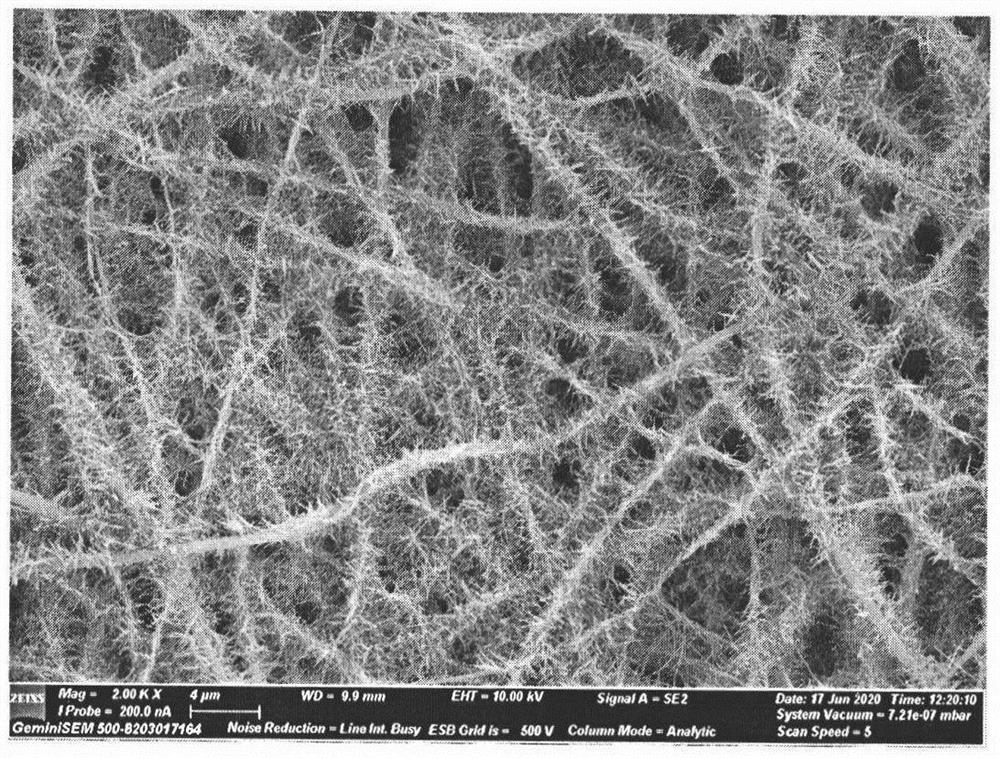

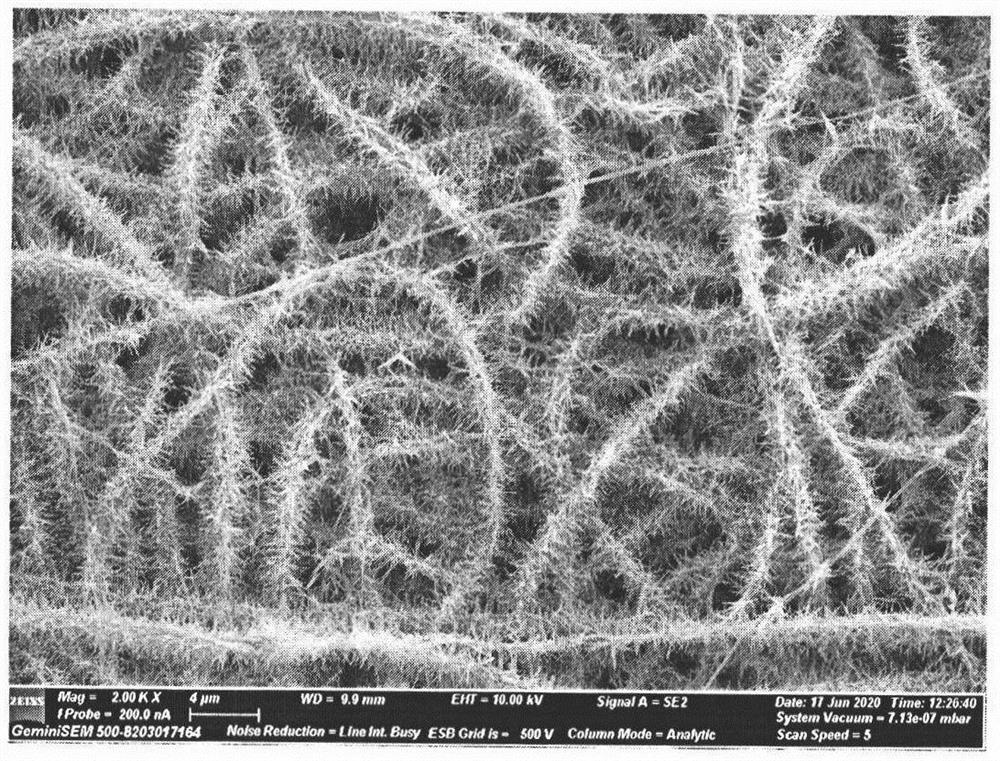

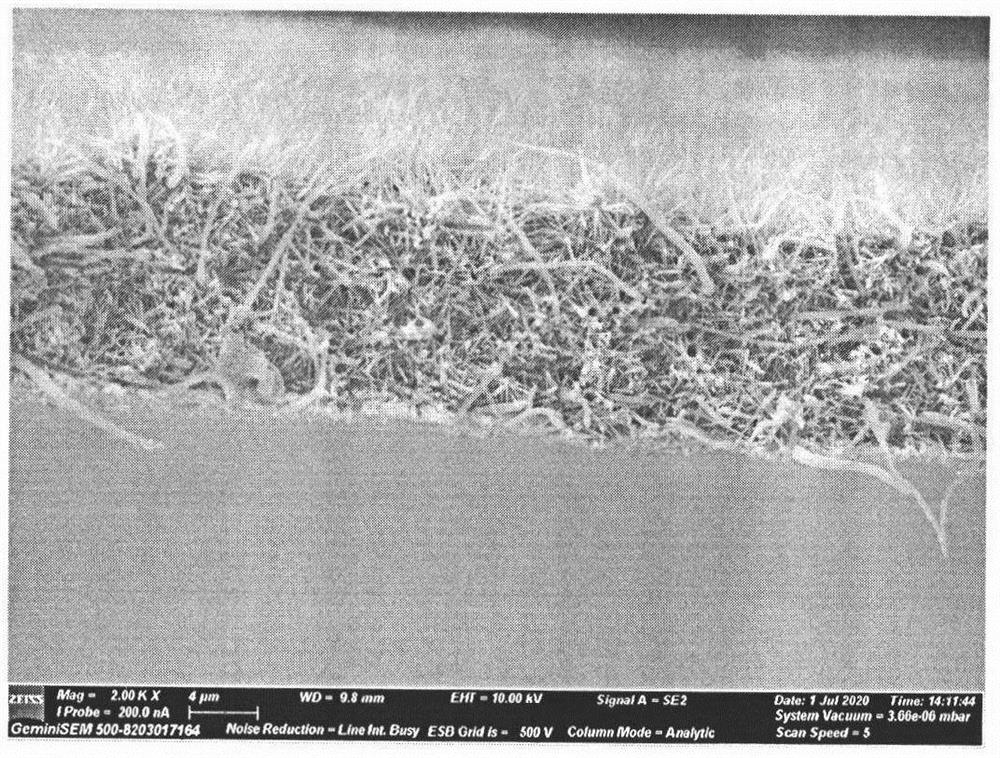

Image

Examples

Embodiment 1

[0026] (1) Preparation of polyvinylidene fluoride / zinc acetate nanofiber membrane: Add PVDF powder and zinc acetate to N,N-dimethylformamide and acetone solution, stir at 90°C to make PVDF powder and zinc acetate completely The solution is spun by electrospinning technology to obtain a polyvinylidene fluoride / zinc acetate nanofiber film, the zinc acetate accounts for 1.5% by mass of the PVDF powder, and the concentration of the PVDF solution is 17%, N, The mass ratio of N-dimethylformamide and acetone is 3:1.

[0027] (2) Preparation of polyvinylidene fluoride / zinc oxide nanofiber membrane: the polyvinylidene fluoride / zinc acetate nanofiber membrane was placed in an oven for heat treatment at a temperature of 130° C., and the heat treatment time was 12 hours.

[0028] (3) Preparation of zinc oxide@polyvinylidene fluoride nanofiber membrane: Soak the polyvinylidene fluoride / zinc oxide nanofiber membrane in absolute ethanol for 10 minutes, and then put it in a mixture of hexamet...

Embodiment 2

[0030] (1) Preparation of polyvinylidene fluoride / zinc acetate nanofiber membrane: Add PVDF powder and zinc acetate to N,N-dimethylformamide and acetone solution, stir at 90°C to make PVDF powder and zinc acetate completely The solution is spun by electrospinning technology to obtain a polyvinylidene fluoride / zinc acetate nanofiber film, the zinc acetate accounts for 1.5% by mass of the PVDF powder, and the concentration of the PVDF solution is 17%, N, The mass ratio of N-dimethylformamide and acetone is 3:1.

[0031] (2) Preparation of polyvinylidene fluoride / zinc oxide nanofiber membrane: the polyvinylidene fluoride / zinc acetate nanofiber membrane was placed in an oven for heat treatment at a temperature of 130° C., and the heat treatment time was 12 hours.

[0032] (3) Preparation of zinc oxide@polyvinylidene fluoride nanofiber membrane: Soak the polyvinylidene fluoride / zinc oxide nanofiber membrane in absolute ethanol for 10 minutes, and then put it in a mixture of hexamet...

Embodiment 3

[0035](1) Preparation of polyvinylidene fluoride / zinc acetate nanofiber membrane: Add PVDF powder and zinc acetate to N,N-dimethylformamide and acetone solution, stir at 90°C to make PVDF powder and zinc acetate completely The solution is spun by electrospinning technology to obtain a polyvinylidene fluoride / zinc acetate nanofiber film, the zinc acetate accounts for 1.5% by mass of the PVDF powder, and the concentration of the PVDF solution is 17%, N, The mass ratio of N-dimethylformamide and acetone is 3:1.

[0036] (2) Preparation of polyvinylidene fluoride / zinc oxide nanofiber membrane: the polyvinylidene fluoride / zinc acetate nanofiber membrane was placed in an oven for heat treatment at a temperature of 130° C., and the heat treatment time was 12 hours.

[0037] (3) Preparation of zinc oxide@polyvinylidene fluoride nanofilm: Soak polyvinylidene fluoride / zinc oxide nanofiber film in absolute ethanol for 10 minutes, and then put it in the water of hexamethylenetetramine, zi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com