Hardened high-toughness titanium carbonitride-based metal ceramic of island-shaped structure and preparation method thereof

A cermet and titanium carbonitride technology, applied in the field of cermet material preparation, can solve the problem that cermet cannot obtain high hardness and high toughness at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

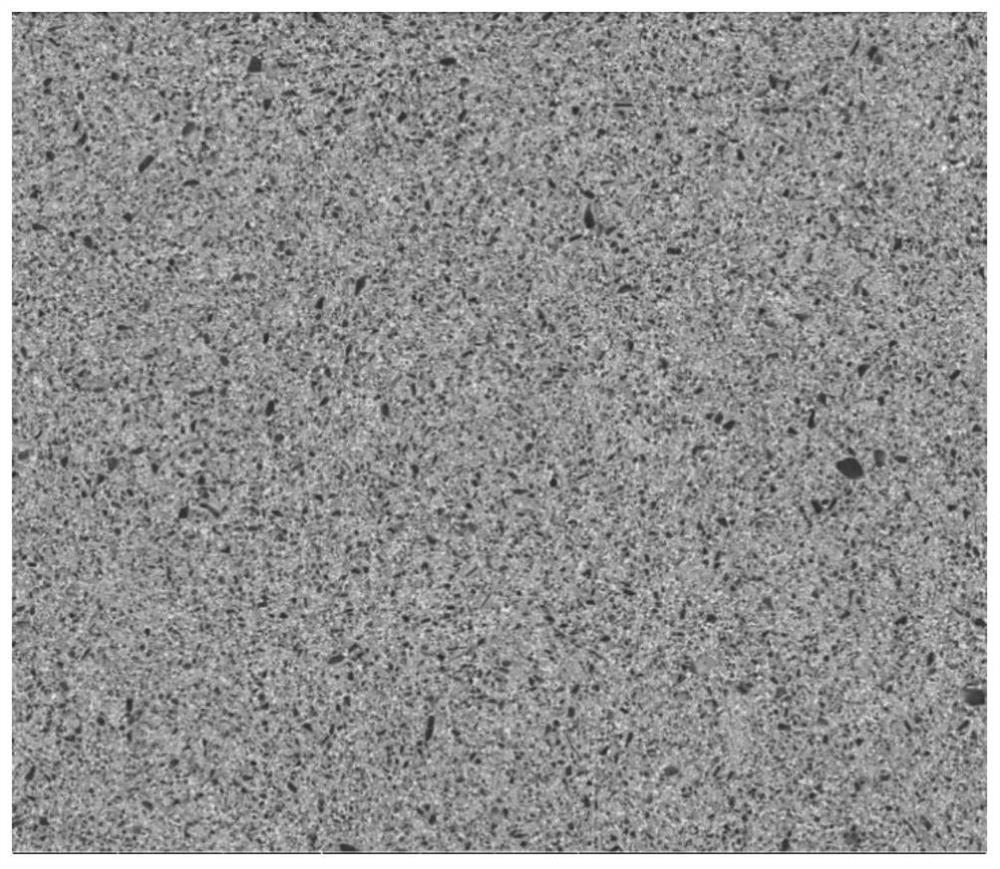

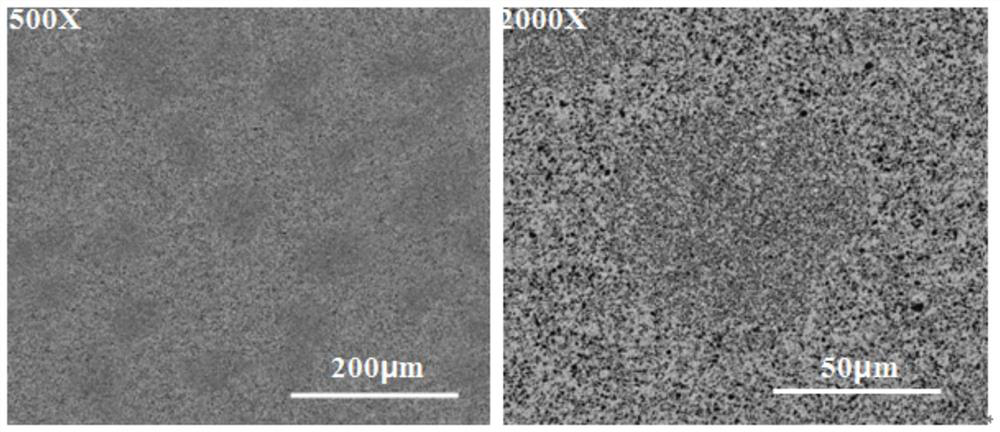

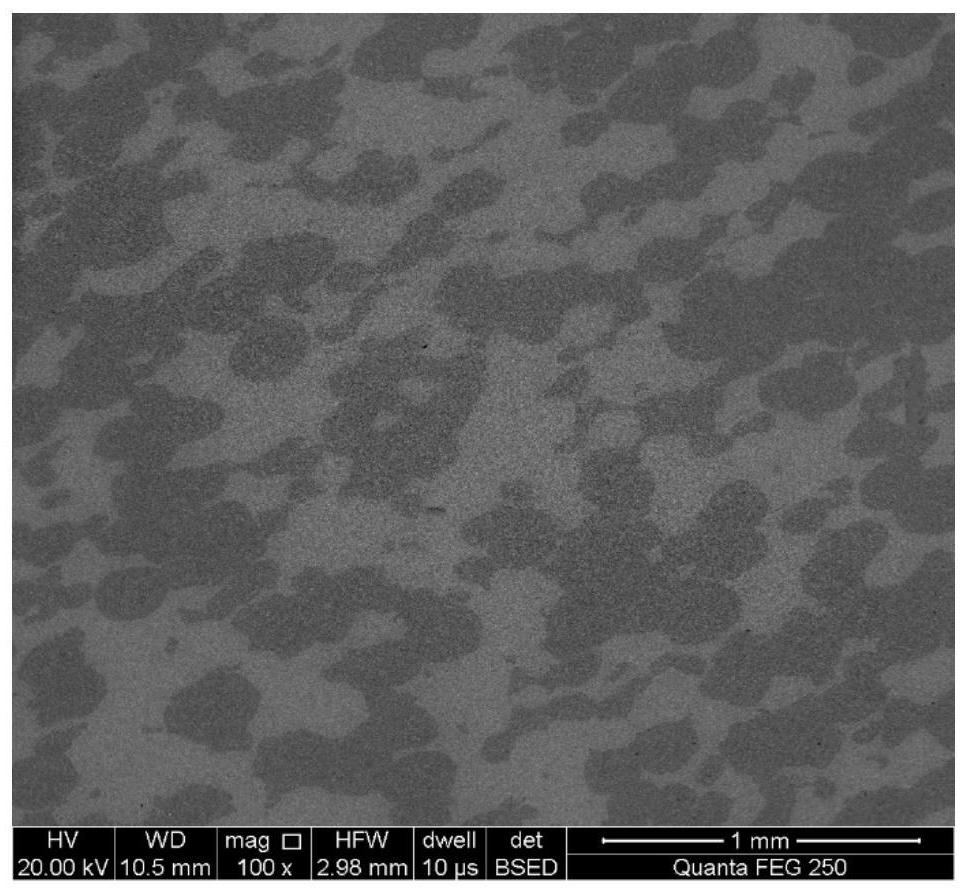

Embodiment 1

[0057] According to the design of the cermet material composition, the raw materials are prepared according to the mass percentage, high-binder phase particles: 54% titanium carbonitride, 15% tungsten carbide, 8% molybdenum carbide, 5% tantalum carbide, 9% cobalt, 9% nickel, Carbon black 0.4%; low binder phase particles: titanium carbonitride 62%, tungsten carbide 15%, molybdenum carbide 8%, tantalum carbide 5%, cobalt 4%, nickel 4%, carbon black 0.4%. The mixed powder of the two components was ball milled and mixed at a speed of 100r / min for 48 hours in a roller ball mill with a ball-to-material ratio of 6:1, and then 4wt% of paraffin was added to the resulting mixed powder as a molding agent, stirred evenly, and The two component powders were subjected to spray granulation, and by adjusting the spray parameters, the average particle size of the high-binding phase particles was 150 μm, and the average particle size of the low-binding phase particles was 80 μm. The two compone...

Embodiment 2

[0059] According to the design of the cermet material composition, the raw materials are prepared according to the mass percentage, high-binder phase particles: 48% titanium carbonitride, 15% tungsten carbide, 10% molybdenum carbide, 5% tantalum carbide, 9% cobalt, 9% nickel, Carbon black 0.3%; low binder phase particles: titanium carbonitride 55%, tungsten carbide 20%, molybdenum carbide 10%, tantalum carbide 5%, cobalt 5%, nickel 5%, carbon black 0.3%. The mixed powders of the two components were ball milled and mixed at a speed of 100 r / min for 48 hours in a roller ball mill with a ball-to-material ratio of 6:1, and then 3 wt % of paraffin was added to the resulting mixed powders as a molding agent, stirred evenly, and The two component powders were subjected to spray granulation, and by adjusting the spray parameters, the average particle size of the high-binding phase particles was 170 μm, and the average particle size of the low-binding phase particles was 70 μm. The two...

Embodiment 3

[0061] According to the design of the cermet material composition, the raw materials are prepared according to the mass percentage, high-binder phase particles: 54% titanium carbonitride, 14% tungsten carbide, 7% molybdenum carbide, 5% tantalum carbide, 10% cobalt, 10% nickel, Carbon black 0.5%; low binder phase particles: titanium carbonitride 58%, tungsten carbide 17%, molybdenum carbide 8%, tantalum carbide 5%, cobalt 6%, nickel 6%, carbon black 0.5%. The mixed powders of the two components were ball milled and mixed at a speed of 100 r / min for 48 hours in a roller ball mill with a ball-to-material ratio of 6:1, and then 3 wt % of paraffin was added to the resulting mixed powders as a molding agent, stirred evenly, and The two component powders were subjected to spray granulation, and by adjusting the spray parameters, the average particle size of the high-binding phase particles was 150 μm, and the average particle size of the low-binding phase particles was 70 μm. The two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com