Preparation method of super-hydrophobic flame-retardant coating with excellent performance

A flame-retardant coating, super-hydrophobic technology, applied in coatings, fire-retardant coatings, epoxy resin coatings, etc., can solve the problems of affecting the performance of coatings, loss of lyophobicity of coatings, and difficulty in large-scale industrial application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

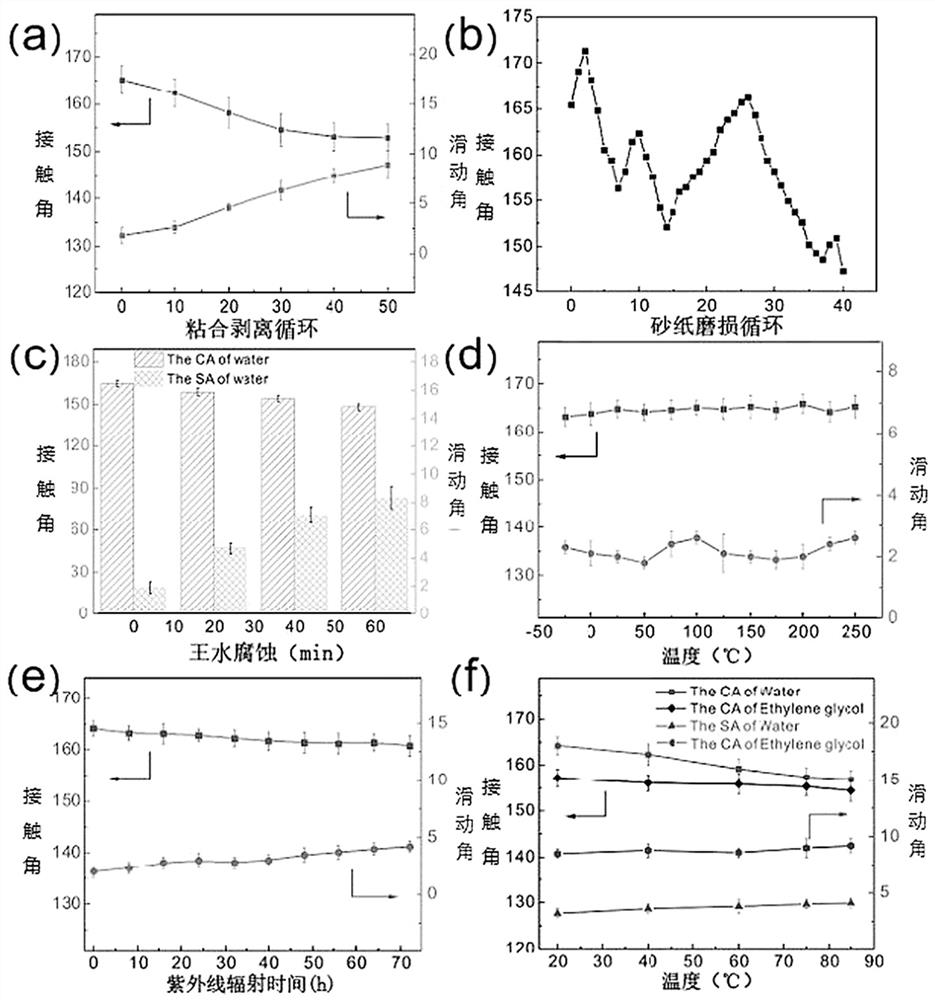

[0029] The superhydrophobic flame-retardant coating of the present invention was tested on the mechanical stability, the chemical stability of the coating and the flame-retardant performance of the coating respectively. In the mechanical stability test, two physical damage methods (sandpaper abrasion and tape peeling) were selected to test the mechanical stability of the multifunctional coating on the glass substrate; in the coating chemical stability test, the strong corrosive environment, Extreme temperature environment, ultraviolet radiation and thermal fluid impact are tested; in the flame retardant performance test of the coating, smoke density test, limiting oxygen index and contact angle test are selected.

[0030] Such as Figure 1-2 as shown, figure 1 middle, figure 1 (a-b) is coating mechanical property test; Wherein, figure 1 (a) for the coating peel test; figure 1 (b) is the coating friction cycle test. figure 1 (c-f) is coating chemical stability test; figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com