Carbon steel corrosion inhibitor containing arginine derivative and preparation method and application of carbon steel corrosion inhibitor

A technology of arginine derivatives and corrosion inhibitors, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., to achieve excellent corrosion inhibition effect, good permeability, and the effect of inhibiting foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of carbon steel corrosion inhibitor containing arginine derivative in the present embodiment is made up of the raw material of following mass percentage:

[0036] Arginine derivatives 45% sodium sebacate 15% 2-Propylheptanol polyoxyethylene ether (A 10 EO 9 )

10% ethanol 10% Sodium molybdate 1% Deionized water 19%

[0037] The preparation method of the above-mentioned carbon steel corrosion inhibitor containing arginine derivatives:

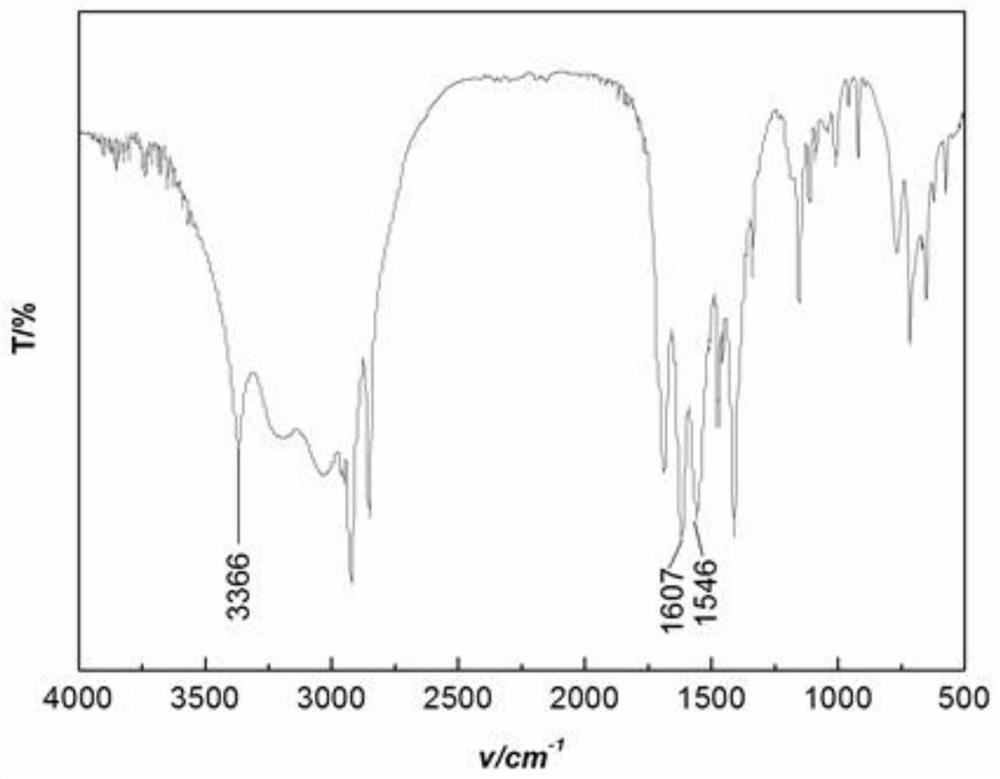

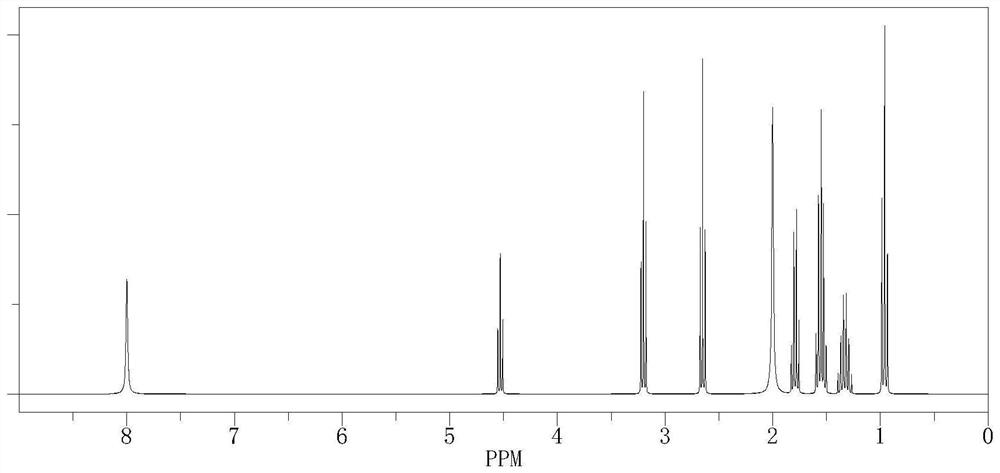

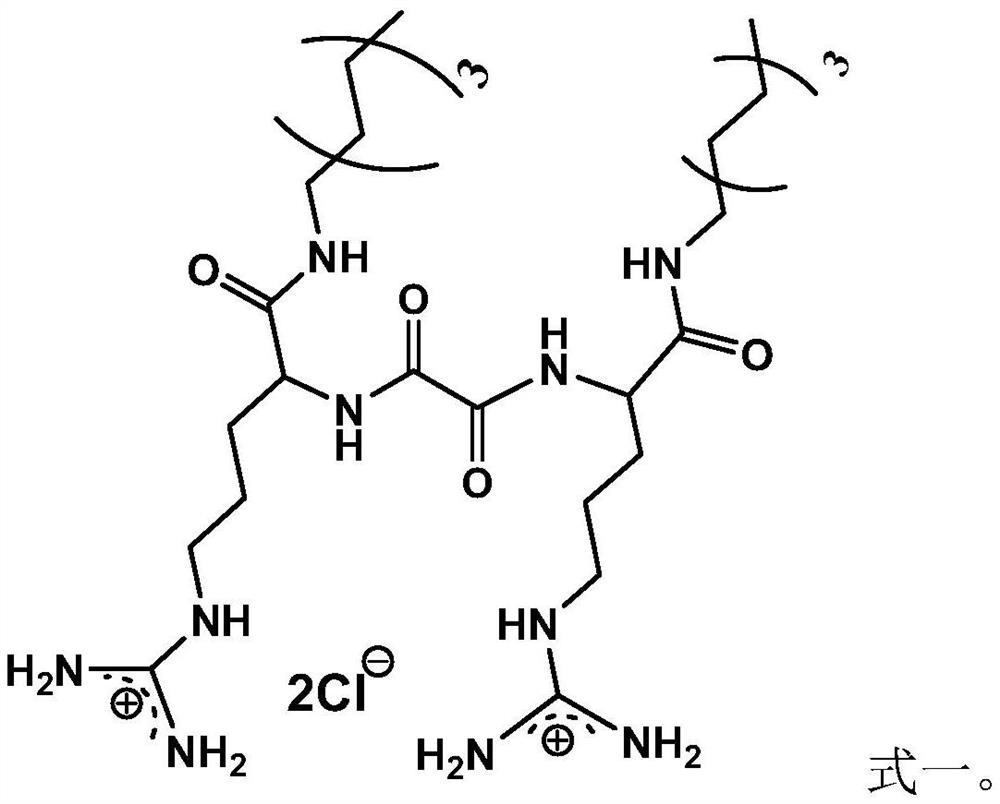

[0038] 1. Preparation of Arginine Derivatives

[0039] In a reactor with a stirrer, a thermometer and a water separator, mix 174g (1mol) L-arginine hydrochloride and 258g (2mol) n-octylamine evenly under nitrogen protection, and slowly heat to 100-150 ℃, add 0.5g concentrated sulfuric acid catalyst at the same time, react under stirring condition for 2-3 hours, cool down to 30-40 ℃ after the reaction, then slowly drop 64g (0.5mol) oxalyl chloride in the reactor under the protection...

Embodiment 2

[0045] A kind of carbon steel corrosion inhibitor containing arginine derivative in the present embodiment is made up of the raw material of following mass percentage:

[0046] Arginine derivatives 40% Sodium Azelate 15% 2-Propylheptanol polyoxyethylene ether (A 10 EO 3 )

5% Methanol 15% Sterol 1.5% Deionized water 23.5%

[0047] The preparation method of the above-mentioned carbon steel corrosion inhibitor containing arginine derivatives:

[0048] 1. Preparation of Arginine Derivatives

[0049] The preparation process of the arginine derivative is the same as in Example 1.

[0050] 2. Preparation of carbon steel corrosion inhibitor containing arginine derivatives

[0051] Weigh each raw material according to the above mass percentage; add deionized water and low-molecular alcohol into the container, and heat to 40-50°C; then add arginine derivatives, stir thoroughly to dissolve them completely; add to the above solution in ...

Embodiment 3

[0053] A kind of carbon steel corrosion inhibitor containing arginine derivative in the present embodiment is made up of the raw material of following mass percentage:

[0054] Arginine derivatives 30% sodium glutarate 25% 2-Hexyldecyl alcohol polyoxyethylene ether (A 16 EO 5 )

10% Methanol 15% polymaleic acid 1.2% Deionized water 18.8%

[0055] The preparation method of the above-mentioned carbon steel corrosion inhibitor containing arginine derivatives:

[0056] 1. Preparation of Arginine Derivatives

[0057] The preparation process of the arginine derivative is the same as in Example 1.

[0058] 2. Preparation of carbon steel corrosion inhibitor containing arginine derivatives

[0059] Weigh each raw material according to the above mass percentage; add deionized water and low-molecular alcohol into the container, and heat to 40-50°C; then add arginine derivatives, stir thoroughly to dissolve them completely; add to the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com