Preparation method of UV viscosity reducing protective film

A technology of protective film and base film, applied in the direction of adhesives, polymer adhesive additives, film/sheet-like adhesives, etc. and other problems, to achieve the effect of high peel strength and reduced peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

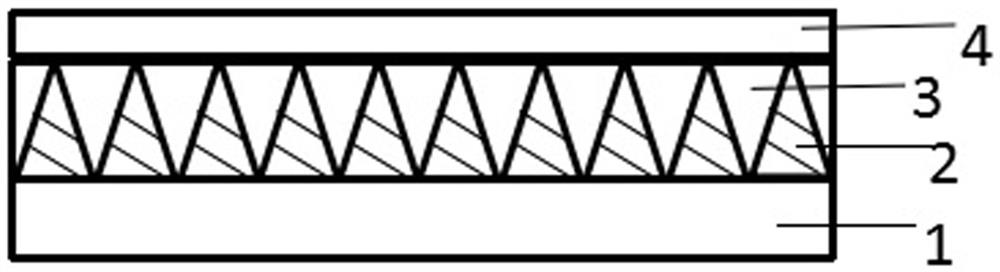

[0031] Embodiment one, the preparation method of above-mentioned UV viscosity-reducing protective film, comprises the following steps:

[0032] S1. The copolyester layer raw material and the PET base layer raw material are respectively extruded through two extruders and then co-extruded to form a base film.

[0033] S2. The base film is stretched longitudinally and transversely to form a stretched film.

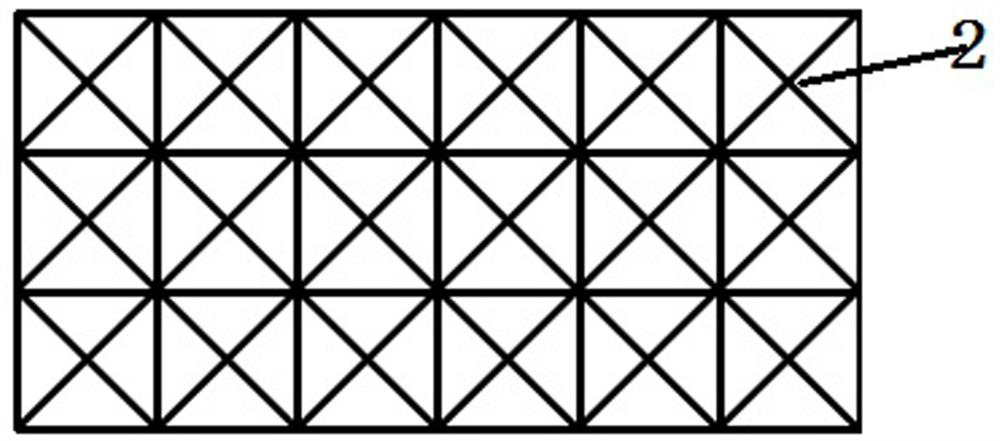

[0034] S3. Extrude a number of rectangular pyramids distributed on the copolyester layer with a patterned heated molding roller, each quadrangular pyramid has the same shape and size, and the projection of the apex of each quadrangular pyramid is located on the bottom surface of the quadrangular pyramid The center of the adjacent quadrangular pyramids share a base.

[0035] S4. Treating the surface of the base film to increase the surface roughness, that is, corona treatment.

[0036] S5. Fill the space between the quadrangular pyramids with an ultraviolet debonding layer, ...

Embodiment 2

[0044] Embodiment two, the preparation method of above-mentioned UV viscosity-reducing protective film, comprises the following steps:

[0045] S1. The copolyester layer raw material and the PET base layer raw material are respectively extruded through two extruders and then co-extruded to form a base film.

[0046] S2. The base film is stretched longitudinally and transversely to form a stretched film.

[0047] S3. Extrude a number of rectangular pyramids distributed on the copolyester layer with a patterned heated molding roller, each quadrangular pyramid has the same shape and size, and the projection of the apex of each quadrangular pyramid is located on the bottom surface of the quadrangular pyramid The center of the adjacent quadrangular pyramids share a base.

[0048] S4. Treating the surface of the base film to increase the surface roughness, that is, plasma treatment.

[0049] S5. Fill the space between the quadrangular pyramids with an ultraviolet debonding layer, ...

Embodiment 3

[0057] Embodiment three, the preparation method of above-mentioned UV viscosity-reducing protective film, comprises the following steps:

[0058] S1. The copolyester layer raw material and the PET base layer raw material are respectively extruded through two extruders and then co-extruded to form a base film.

[0059] S2. The base film is stretched longitudinally and transversely to form a stretched film.

[0060] S3. Extrude a number of rectangular pyramids distributed on the copolyester layer with a patterned heated molding roller, each quadrangular pyramid has the same shape and size, and the projection of the apex of each quadrangular pyramid is located on the bottom surface of the quadrangular pyramid The center of the adjacent quadrangular pyramids share a base.

[0061] S4. Treating the surface of the base film to increase the surface roughness, that is, corona treatment.

[0062] S5. Fill the space between the quadrangular pyramids with an ultraviolet debonding layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com