High-load narrow V-belt and preparation method thereof

A high-load, montmorillonite technology, applied in coatings and other directions, can solve the problems of insufficient strength and load, reduced V-belt strength, no deep connection, etc., to achieve excellent mechanical properties, improve processing characteristics, and reduce processing difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

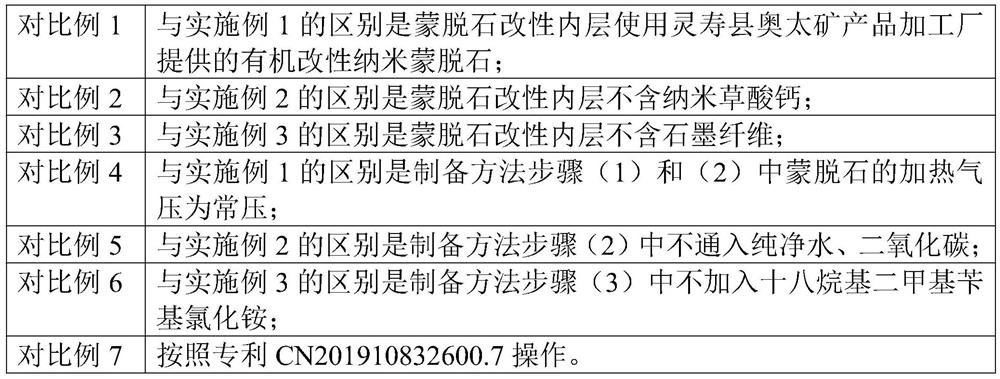

Examples

Embodiment 1

[0025] A high-load narrow V-belt, comprising a fiber adhesion layer and a montmorillonite modified inner layer, the fiber adhesion layer is wrapped on the surface of the montmorillonite modified inner layer; the montmorillonite modified inner layer consists of the following Prepared from raw materials in parts by mass: 10 parts of nitrile rubber, 20 parts of chlorinated nitrile rubber, 40 parts of styrene-butadiene rubber, 70 parts of EPDM rubber, 3 parts of bismaleimide resin, polyarylether ketone 20 parts, 25 parts of polyarylethersulfone, 1 part of nano-calcium silicate, 1 part of nano-barium silicate, 1 part of nano-calcium oxalate, 3 parts of modified montmorillonite; the fiber adhesion layer consists of the following parts by mass of raw materials Prepared from: 60 parts of chlorosulfonated polyethylene rubber, 20 parts of fluororubber, 50 parts of butadiene rubber, 1 part of graphite fiber, 1 part of silicon carbide fiber, and 5 parts of polyparaphenylene benzobisoxazole...

Embodiment 2

[0033] A high-load narrow V-belt, comprising a fiber adhesion layer and a montmorillonite modified inner layer, the fiber adhesion layer is wrapped on the surface of the montmorillonite modified inner layer; the montmorillonite modified inner layer consists of the following Prepared from raw materials in parts by mass: 15 parts of nitrile rubber, 30 parts of chlorinated nitrile rubber, 50 parts of styrene-butadiene rubber, 80 parts of EPDM rubber, 5 parts of bismaleimide resin, polyarylether ketone 30 parts, 35 parts of polyarylethersulfone, 3 parts of nano-calcium silicate, 3 parts of nano-barium silicate, 3 parts of nano-calcium oxalate, 5 parts of modified montmorillonite; the fiber adhesion layer consists of the following parts by mass of raw materials Prepared from: 90 parts of chlorosulfonated polyethylene rubber, 30 parts of fluorine rubber, 60 parts of butadiene rubber, 3 parts of graphite fiber, 3 parts of silicon carbide fiber, and 13 parts of polyparaphenylene benzob...

Embodiment 3

[0041] A high-load narrow V-belt, comprising a fiber adhesion layer and a montmorillonite modified inner layer, the fiber adhesion layer is wrapped on the surface of the montmorillonite modified inner layer; the montmorillonite modified inner layer consists of the following Prepared from raw materials in parts by mass: 13 parts of nitrile rubber, 25 parts of chlorinated nitrile rubber, 47 parts of styrene-butadiene rubber, 78 parts of EPDM rubber, 4 parts of bismaleimide resin, polyarylether ketone 21 parts, 26 parts of polyarylether sulfone, 3 parts of nano-calcium silicate, 1 part of nano-barium silicate, 3 parts of nano-calcium oxalate, 3 parts of modified montmorillonite; the fiber adhesion layer consists of the following parts by mass of raw materials Prepared from: 90 parts of chlorosulfonated polyethylene rubber, 20 parts of fluororubber, 60 parts of butadiene rubber, 1 part of graphite fiber, 3 parts of silicon carbide fiber, and 5 parts of polyparaphenylene benzobisoxa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com