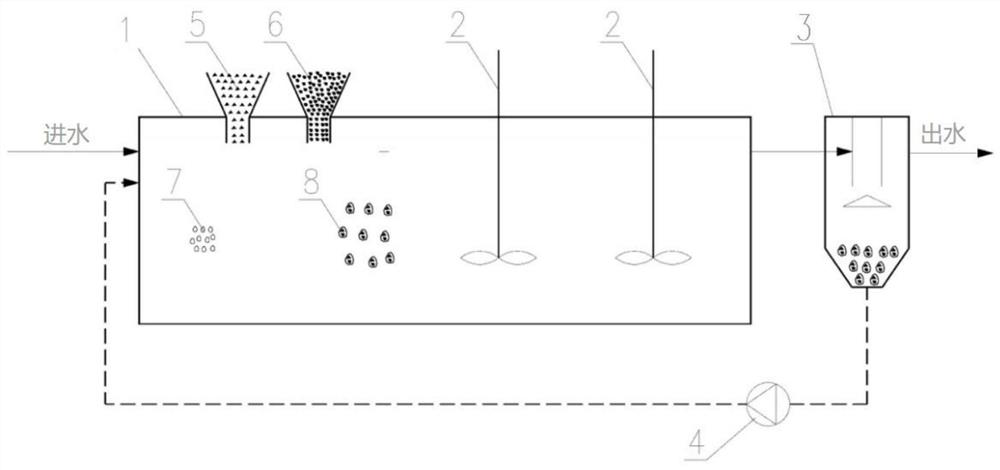

Method for treating wastewater by coupling iron-carbon micro-electrolysis and anaerobic organisms

An iron-carbon micro-electrolysis and anaerobic biological technology, applied in electrochemical biological treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve problems such as neglect of organic bonding, waste of resources, and long wastewater treatment process. , to achieve the effect of enhancing sedimentation performance, saving acid consumption, and enhancing anaerobic biochemical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The wastewater treatment station for a printing and dyeing factory handles 3,000 tons of wastewater per day. The wastewater treatment process is pretreatment-anaerobic biochemical treatment-aerobic biochemical treatment-nanotube discharge. After pretreatment (that is, before entering anaerobic biochemical process), the chroma is about 200 times, the CODcr concentration is about 2000mg / L, and the BOD 5 The concentration is about 300mg / L, that is, B:C=0.15. Anaerobic biochemical treatment is stirred by a submersible mixer with a stirring power of 8W / m 3 , hydraulic retention time 8 hours, anaerobic reaction temperature 30 ℃. After anaerobic biochemical treatment, the chromaticity is reduced to about 120 times, the CODcr concentration is reduced to about 1600mg / L, and the BOD 5 The concentration rises to about 420mg / L, ie B:C=0.2625.

[0057] After the renovation of the wastewater treatment station, the measures of adding iron powder and carbon powder are added (except ...

Embodiment 2

[0061] On the basis of embodiment 1, when outdoor temperature is lower than 15 ℃ (simultaneously inflow temperature also reduces to below 12 ℃ thereupon), adopt following measures to ensure the operation and reaction rate of anaerobic reaction:

[0062] 1. Install a rock wool board insulation layer outside the water inlet pool, and install an insulation wrapping layer outside the water inlet pipe and anaerobic reactor: the inner layer of sponge and the outer layer of tin foil.

[0063] 2. Place the steam heat exchanger in the water inlet tank of the anaerobic reactor to heat the water directly; and another steam heat exchanger is placed on the side of the water inlet in the anaerobic reactor to Liquid systems are heated:

[0064] The steam temperature and heating time control in the heating process are obtained by the following algorithm:

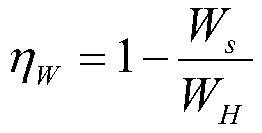

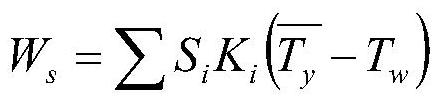

[0065] Assume that the effective utilization rate of energy in the heating process is:

[0066]

[0067] Among them, W s is the heat...

Embodiment 3

[0079] A comprehensive sewage treatment plant supporting a fine chemical industrial park handles 10,000 tons of wastewater per day. The wastewater treatment process is pretreatment-anaerobic biochemical treatment-aerobic biochemical treatment-ozone advanced oxidation-discharge water. Anaerobic biochemical treatment adopts UASB reactor. Due to the unsatisfactory effect of anaerobic treatment, the subsequent treatment pressure is relatively high, and the dosage of ozone needs to reach 150g / m 3 The above can make the factory water meet the standard, and the cost of ozone treatment is as high as 1.2 yuan / ton of water.

[0080] In order to reduce the operating cost under the premise of ensuring that the effluent meets the standard, the sewage plant is technically transformed by coupling iron-carbon reaction and anaerobic biochemistry to improve the effect of anaerobic treatment:

[0081] On the basis of keeping the other parameters unchanged, add iron powder and carbon powder into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com