A kind of high anti-cracking foam concrete and preparation method thereof

A technology of foam concrete and high crack resistance, applied in the field of building materials, can solve the problems of large water-binder ratio of foam concrete, limit the application of foam concrete, and large shrinkage of foam concrete, so as to reduce pore size, improve shrinkage and crack resistance , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

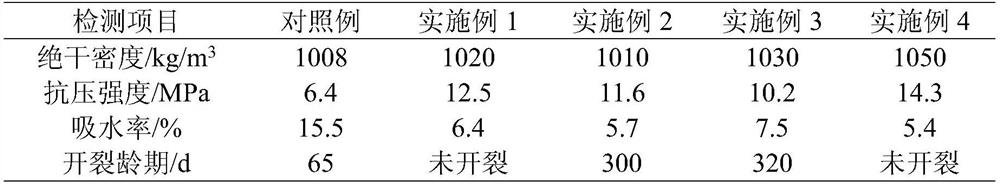

Examples

Embodiment approach 1

[0040] This embodiment provides a high-crack-resistant foam concrete, which consists of the following parts by mass: 1000 parts of cement, 300 parts of fly ash, 500 parts of slag powder, 2 parts of acrylic water-absorbing resin, 5 parts of nano-silica reinforced foaming agent, 300 parts of weakly alkaline water with PH=9, 900 parts of water, 360 parts of shale ceramsite smaller than 10mm and 8 parts of crop straw fiber.

[0041] The concrete preparation steps of above-mentioned high anti-cracking foam concrete are as follows:

[0042] 1) Stir the cement, fly ash, silica fume, water-absorbing resin and water at a speed of 90r / min for 30s in proportion;

[0043] 2) Gradually add shale ceramsite and crop straw fibers to the slurry prepared in step 1) and stir at a speed of 120r / min for 30s;

[0044] 3) Use nano-silica to enhance the foaming agent and PH = 9 weak alkaline water to form foam, and add it to the well-stirred slurry mixture and stir at a speed of 60r / min for 3 minute...

Embodiment approach 2

[0047] This embodiment provides a high-crack-resistant foam concrete, which consists of the following parts by mass: 1000 parts of cement, 100 parts of fly ash, 300 parts of slag powder, 3 parts of ammonium acrylate water-absorbing resin, and 2 parts of nano-zinc oxide reinforced foaming agent , 120 parts of weakly alkaline water with pH=9, 700 parts of water, 300 parts of rubber particles with a particle diameter less than 10mm and 5 parts of wood fiber.

[0048] The concrete preparation steps of above-mentioned high anti-cracking foam concrete are as follows:

[0049] 1) Stir the cement, fly ash, silica fume, water-absorbing resin and water at a speed of 90r / min for 30s in proportion;

[0050] 2) Gradually add rubber particles and wood fibers to the slurry prepared in step 1) and stir at a speed of 120r / min for 30s;

[0051] 3) Use nano-zinc oxide to enhance foaming agent and PH = 9 weak alkaline water to form foam, and add it to the well-stirred slurry mixture and stir at ...

Embodiment approach 3

[0054] This embodiment provides highly crack-resistant foam concrete, which consists of the following parts by mass: 800 parts of cement, 100 parts of fly ash, 200 parts of slag powder, 5 parts of methacrylamidopropyltrimethylammonium chloride water-absorbing resin, nano 4 parts of aluminum oxide reinforced foaming agent, 240 parts of weak alkaline water with pH=9, 500 parts of water, 200 parts of sand with particle diameter less than 10mm and 3 parts of hemp fiber.

[0055] The concrete preparation steps of above-mentioned high anti-cracking foam concrete are as follows:

[0056] 1) Stir the cement, fly ash, silica fume, water-absorbing resin and water at a speed of 90r / min for 30s in proportion;

[0057] 2) Gradually add sand and hemp fiber to the slurry prepared in step 1) and stir at a speed of 120r / min for 30s;

[0058] 3) Use nano-alumina to enhance the foaming agent and PH = 9 weak alkaline water to form foam, and add it to the well-stirred slurry mixture and stir at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com