High-power LED lamp heat dissipation device

A technology of LED lamps and heat sinks, which is applied to the cooling/heating devices of lighting devices, lighting devices, components of lighting devices, etc., can solve the problem that the heat exchange performance needs to be further improved, the work adaptability is poor, and the reflux of condensing working fluid is blocked. and other problems, to achieve excellent work adaptability, improve the drying limit, improve the temperature uniformity and heat transfer limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

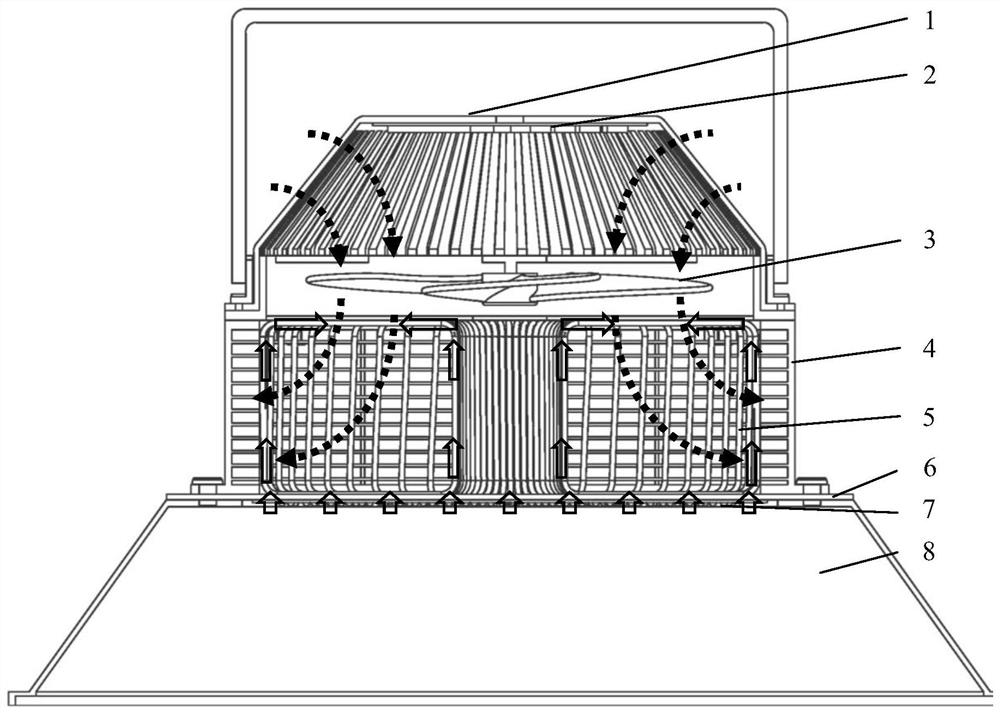

[0024] Such as Figure 1-2 As shown, a high-power LED lamp cooling device consists of an upper lampshade 1, a circuit board 2, a cooling fan 3, a finned shell 4, a gas-liquid pulsation phase change heat pipe 5, a mounting base 6, and an LED bead integrated board 7 , lower lampshade 8, and glass cover plate 9 parts are assembled. The gas-liquid pulsation phase change heat pipe 5 is vertically and closely installed on the installation surface of the preset installation groove 602 of the installation base 6, and the contact pipe section forms an endothermic evaporation section, and the remaining pipe sections are heat release condensation sections; the other side of the installation base 6 The LED lamp bead integrated board 7 is then coaxially bonded; each contact surface is connected with a high-temperature-resistant heat-conducting adhesive. The finned housing 4 is used as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com