Mechanical stripping method of functionalized boron nitride nanosheet

A technology of mechanical exfoliation and boron nitride, applied in the direction of chemical instruments and methods, nitrogen compounds, nanotechnology, etc., can solve the problems of pollution, waste of raw materials, low crystallinity of BNNSs, etc., and achieve energy saving, production cost reduction, crystallization The effect of high degree of degree and functionalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

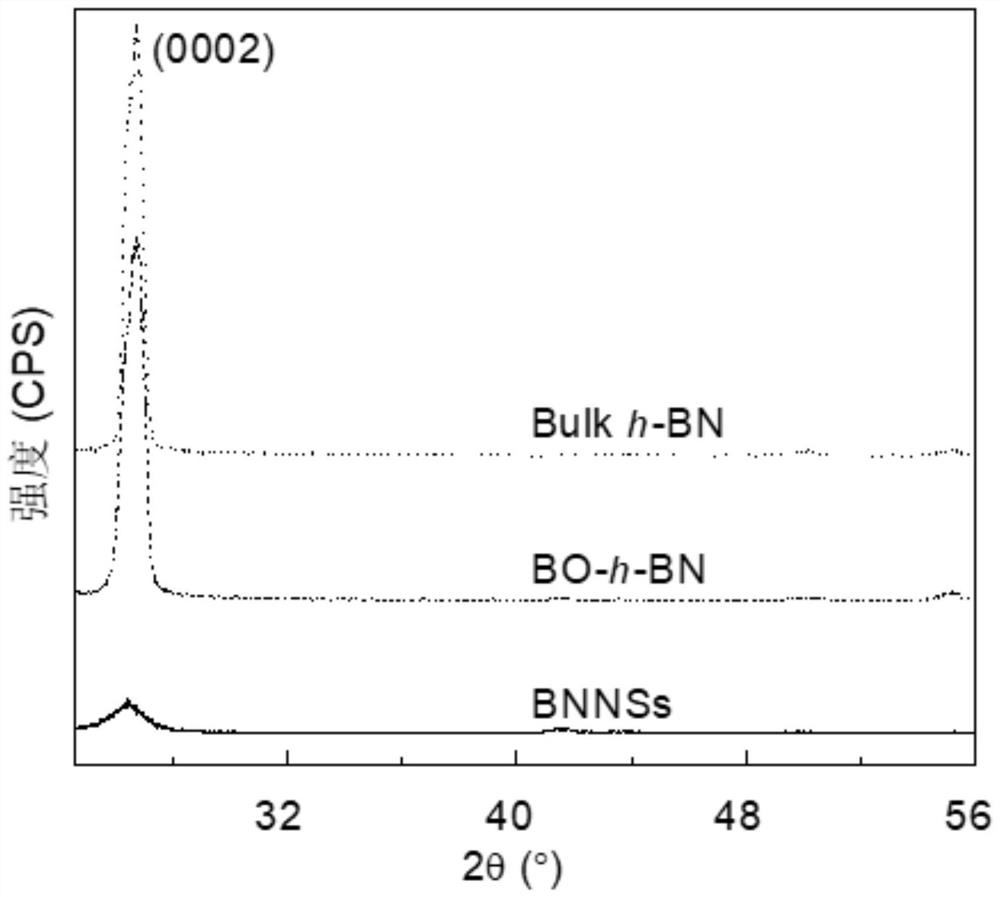

[0031] Step (1): 80 g of boric acid and 10 g of commercial hexagonal boron nitride block (Bulk h-BN) were uniformly ground, put into an autoclave, and treated at 220° C. for 12 hours to obtain a hard white solid A. After the sample A was repeatedly washed with deionized water to remove free boric acid, an intermediate product of BO-h-BN was obtained, which was used for performance testing of pretreated samples.

[0032] Step (2): Put the product A obtained in the step (1) into a ball mill jar, and process it for 6 hours at 580 rpm to obtain product B.

[0033] Step (3): The product B obtained in step (2) is washed with deionized water to remove free boric acid components in the liquid to obtain a high-concentration and stable BNNSs dispersion product; or the wet product obtained by centrifugal cleaning is extracted by freezing Dry to obtain the powder product of functionalized BNNSs.

[0034] Step (4): The supernatant obtained by centrifugal washing in step (3) is processed b...

Embodiment 2、3、4、5

[0038] Change the consumption of boric acid and commercial hexagonal boron nitride into 72g and 18g respectively in embodiment 1 step (1); 75g and 12.5g; 80g and 8g; :1; 6:1; 10:1; 12:1). Other operations are the same as in Example 1, and high crystallinity and functionalized BNNSs dispersion products or powder products can also be prepared. High-quality functionalized BNNSs products could also be prepared by further increasing the amount of boric acid added, but the relative yield decreased.

Embodiment 6、7、8、9、10、11、12、13、14、15

[0040] The autoclave treatment temperature in step (1) in Examples 1-5 was changed to 200° C. and 240° C. respectively. Other operations are the same as in Example 1, and high crystallinity and functionalized BNNSs dispersion products or powder products can also be prepared. The temperature above 200 ° C can realize boric acid dehydration and change into corrosive boron oxide. Purpose of etching and fixing commercial blocks of hexagonal boron nitride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com