Anti-deformation pipe fitting fixing device for machining

A technology of machining and fixing devices, applied in workpiece clamping devices, positioning devices, metal processing machinery parts, etc., can solve problems such as pipe deformation, improve anti-skid performance, ensure fixing effect, and improve the effect of fixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

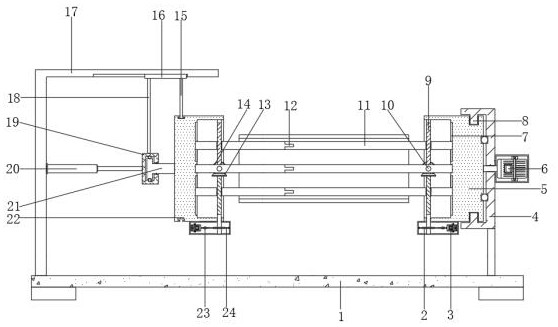

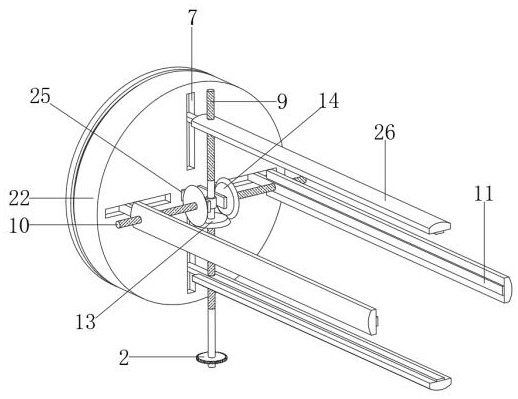

[0030] refer to Figure 1-4 , an anti-deformation pipe fixing device for mechanical processing, comprising a base 1, and brackets and L-shaped fixed vertical plates 17 are respectively welded on both sides of the top outer wall of the base 1, and one side of the L-shaped fixed vertical plate 17 is fixed with hydraulic pressure by bolts. Rod 20, a clamping mechanism is installed on the top of the base 1, and the clamping mechanism includes a fixed installation end 5 and a movable installation end 22, the fixed installation end 5 and the movable installation end 22 are both cylindrical, and the fixed installation end 5 and the movable installation The inner bottom of the end 22 is provided with four evenly distributed limiting chute 7, the inner wall of the limiting chute 7 is slidingly connected with the moving rod 11, and the outer wall of one side of the moving rod 11 is welded with an arc-shaped stop plate 26 , the outer wall of the arc-shaped backing plate 26 is fixedly ins...

Embodiment 2

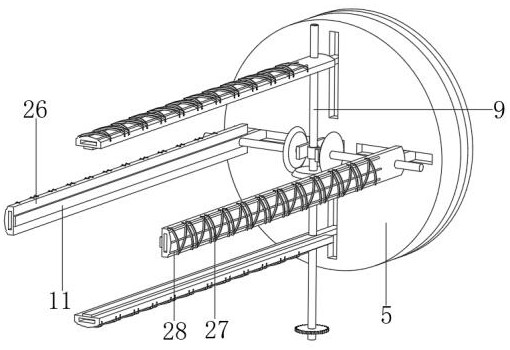

[0041] refer to Figure 5 , an anti-deformation pipe fixing device for mechanical processing. Compared with Embodiment 1, this embodiment also includes that the bottom outer wall of the moving rod 11 is welded with extension blocks distributed equidistantly, and both sides of one end of the extension block are connected by hinges. Arm bar 29 is arranged, and one end of arm bar 29 is all welded with hemispherical block 31, and the outer wall of hemispheric barn 31 is all bonded with the bar edge 32 of equidistant distribution, and the opposite side of extension block and arm bar 29 is all welded with Tension spring 30.

[0042] When the present invention is used, while the arc-shaped support plate 26 supports the pipe fitting, the tension spring 30 can be used to pull the arm bar 29 to approach the corresponding moving rod 11, and then pull the hemispherical block 31 and the strip edge 31 against the inner wall of the pipe fitting. Thereby, the purpose of further improving the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com