Supporting device for high-accuracy adjustable optical elements

An optical element and supporting device technology, applied in optical elements, optics, installation, etc., can solve the problems of inability to effectively overcome the self-weight deformation of optical elements, the accuracy is difficult to meet the requirements of high-precision surface shape, and it does not have the ability to actively deform. Reliable supporting state of components, improving the effect of adjusting the displacement transmission ratio and overcoming deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

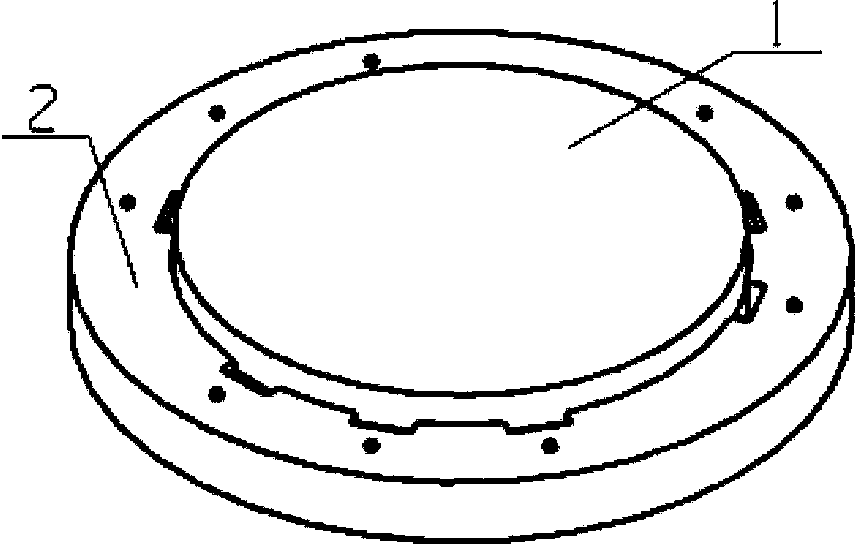

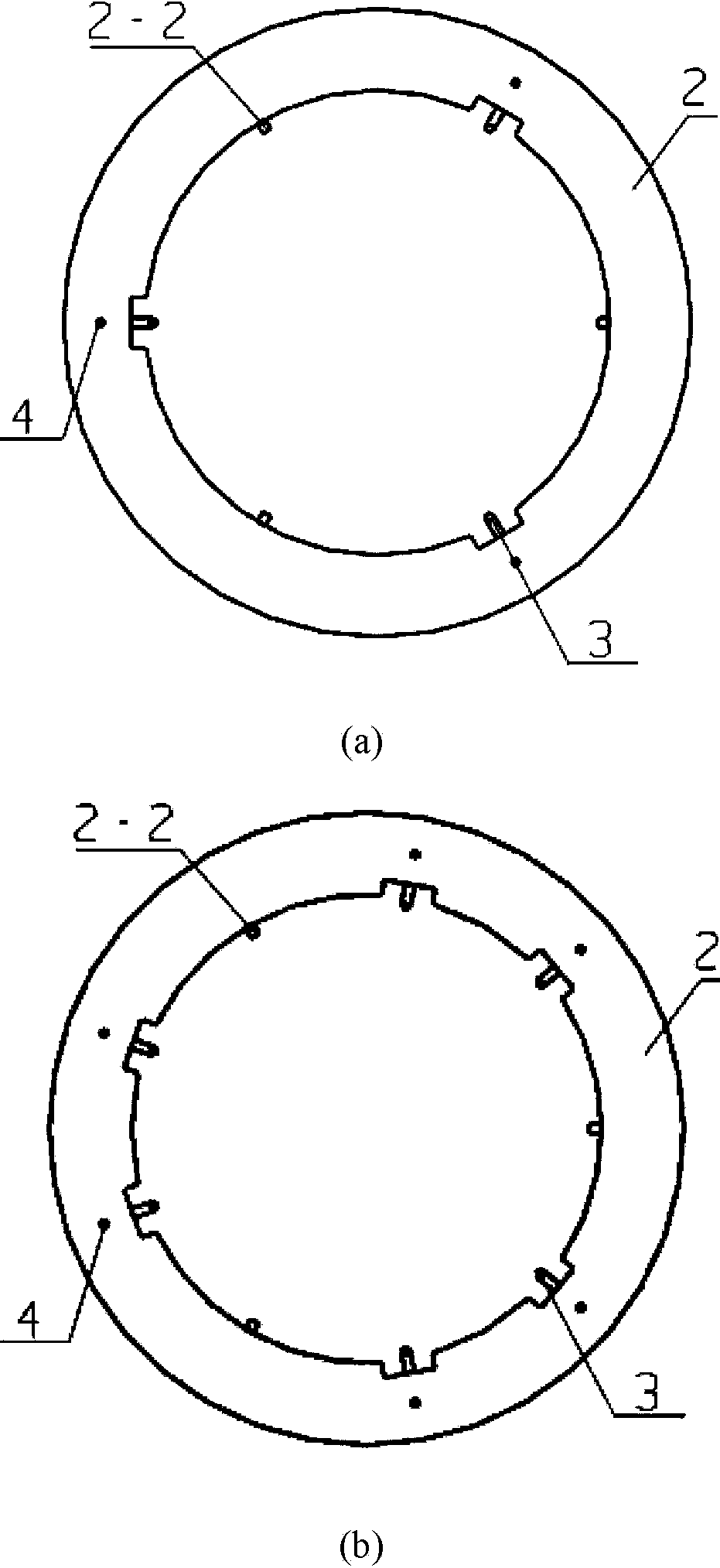

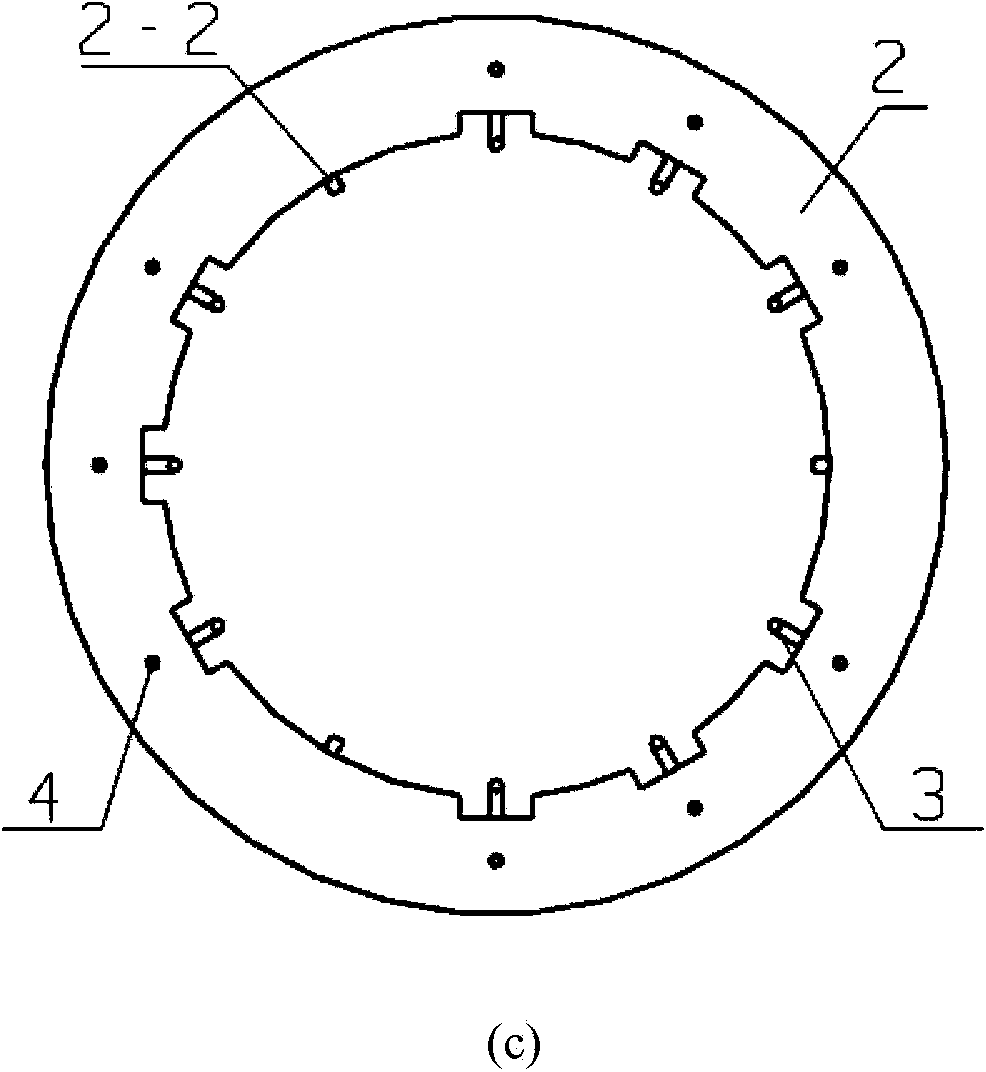

[0020] The inventive idea of the present invention is: a high-precision adjustable optical element support device, which includes: a mirror frame with three-point fixed support, adjustable flexible auxiliary support shrapnel, multi-stage displacement reduction flexible hinge, thread adjustment rod, thread lock Springs, screws.

[0021] The picture frame is the ring-shaped main structure of the support device, which has good rigidity and is generally made of stainless steel or Invar. Adjusting rod and threaded locking spring mounting threaded hole;

[0022] The three-point fixed support is evenly distributed in the circumferential direction of 120°, and its support surface can be designed as a slope tangent to the optical element or a radius of curvature slightly larger than the spherical surface of the optical element, which is convenient for fixing the optical element and the frame with structural glue;

[0023] The number of the adjustable flexible auxiliary support shrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com