High-strength drag reduction type spiral steel pipe for long-distance oil and gas transportation and machining process thereof

A technology of spiral steel pipe and processing technology, applied in the field of spiral steel pipe, can solve the problems of declining service performance of spiral steel pipe, affecting the mechanical properties of welds, affecting the safety and stability of oil and gas transportation, and achieving enhanced residual stress control during forming, strengthening The effect of welding process parameter control and improving docking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

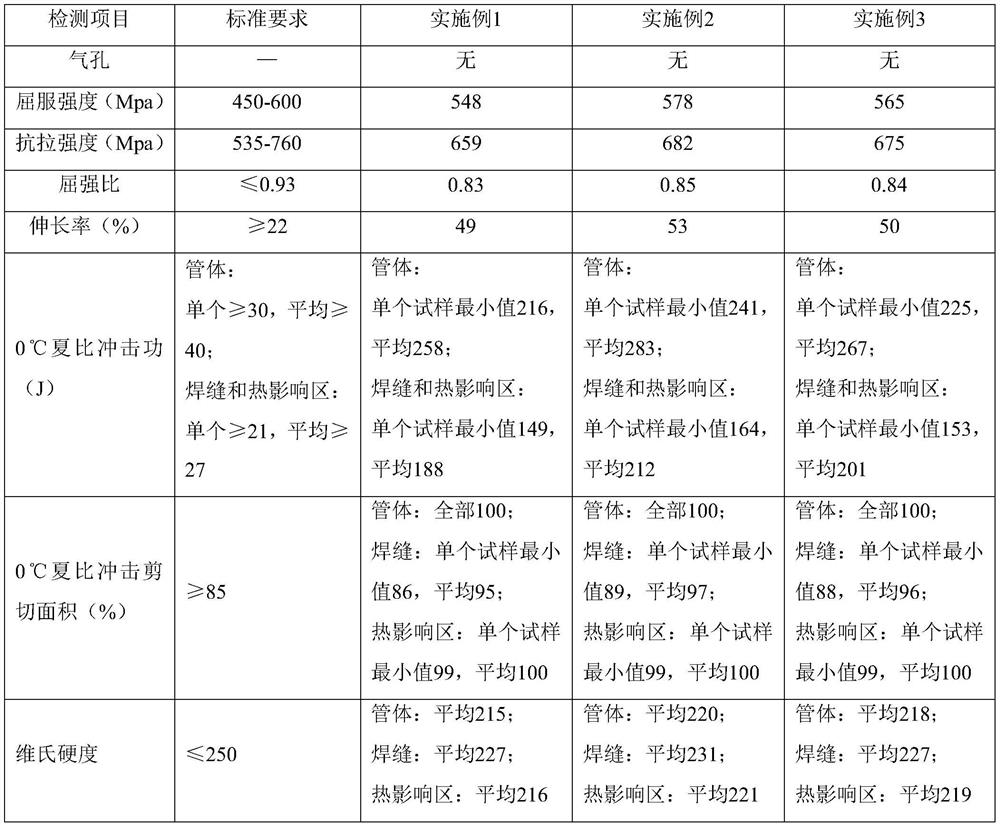

Examples

Embodiment 1

[0044] A high-strength drag-reducing spiral steel pipe for long-distance oil and gas transportation,

[0045] The weight percent of the chemical composition of the base steel plate is: C 0.12%, Si 0.25%, Mn 1.09%, P 0.2%, S0.12%, V 0.024%, Cr 0.04%, Ni 0.0053%, Cu 0.015%, the balance Fe;

[0046] The thickness of the parent steel plate is 8.5mm;

[0047] The yield strength of the parent steel plate is 550Mpa, and the tensile strength is 615Mpa;

[0048] The weight percent of the chemical composition of the spiral weld is: C 0.05%, Si 0.12%, Mn 5.3%, P≤0.15%, S≤0.06%, V 0.052%, Cr 0.02%, Ni 0.22%, Cu 0.09%, Ti 0.027%, B 0.08%, balance Fe;

[0049] The processing technology includes the following steps:

[0050] S1, unwinding and leveling;

[0051] S2, edge milling: adopt double edge milling process, first rough mill I-shaped groove; then fine-mill X-shaped groove, blunt edge 7.0mm, groove angle 70°;

[0052] S3, pre-bending: the size of the pre-bending edge is 490mm in ra...

Embodiment 2

[0060] A high-strength drag-reducing spiral steel pipe for long-distance oil and gas transportation,

[0061] The weight percent of the chemical composition of the base steel plate is: C 0.17%, Si 0.28%, Mn 1.1%, P 0.19%, S0.11%, V 0.02%, Cr 0.05%, Ni 0.01%, Cu 0.02%, the balance Fe;

[0062] The thickness of the base steel plate is 9mm;

[0063] The yield strength of the parent steel plate is 575Mpa, and the tensile strength is 630Mpa;

[0064] The weight percent of the chemical composition of the spiral weld is: C 0.06%, Si 0.13%, Mn 5.5%, P≤0.15%, S≤0.06%, V 0.049%, Cr 0.04%, Ni 0.24%, Cu 0.011%, Ti 0.023%, B 0.05%, balance Fe;

[0065] The processing technology includes the following steps:

[0066] S1, unwinding and leveling;

[0067] S2, edge milling: adopt double edge milling process, first rough mill I-shaped groove; then fine-mill X-shaped groove, the blunt edge is 7.5mm, and the groove angle is 75°;

[0068] S3, pre-bending: the size of the pre-bending edge is ...

Embodiment 3

[0076] A high-strength drag-reducing spiral steel pipe for long-distance oil and gas transportation,

[0077] The weight percent of the chemical composition of the base steel plate is: C 0.2%, Si 0.31%, Mn 1.14%, P 0.15%, S0.09%, V 0.015%, Cr 0.06%, Ni 0.013%, Cu 0.022%, the balance Fe;

[0078] The thickness of the base steel plate is 9.5mm;

[0079] The yield strength of the parent steel plate is 590Mpa, and the tensile strength is 645Mpa;

[0080] The weight percent of the chemical composition of the spiral weld is: C 0.08%, Si 0.16%, Mn 5.8%, P≤0.15%, S≤0.06%, V 0.044%, Cr 0.06%, Ni 0.28%, Cu 0.015%, Ti 0.02%, B 0.02%, balance Fe;

[0081] The processing technology includes the following steps:

[0082] S1, unwinding and leveling;

[0083] S2, edge milling: adopt double edge milling process, first rough mill I-shaped groove; then fine-mill X-shaped groove, blunt edge 8.0mm, groove angle 80°;

[0084] S3, pre-bending: the size of the pre-bending edge is 490mm in radiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com