Glass connection method and device based on frit

A connection method and glass frit technology, applied in the field of glass connection process, can solve the problems of complex heating method, narrow welding window, inability to remove, etc., and achieve the effect of good connection effect, reduction of pores, and avoidance of scrap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The laser sintering method in this embodiment includes the following steps:

[0060] Step 1: ultrasonically clean the glass substrate with a mixture of distilled water and detergent.

[0061]Step 2: The glass paste is coated on the glass substrate by screen printing. Among them, the two screen plates used are screen printing plates with a film thickness of 10 μm. Screen printing pattern width 0.8mm. The final coating thickness is 4-5 μm, that is, a low-thickness glass frit coating is obtained.

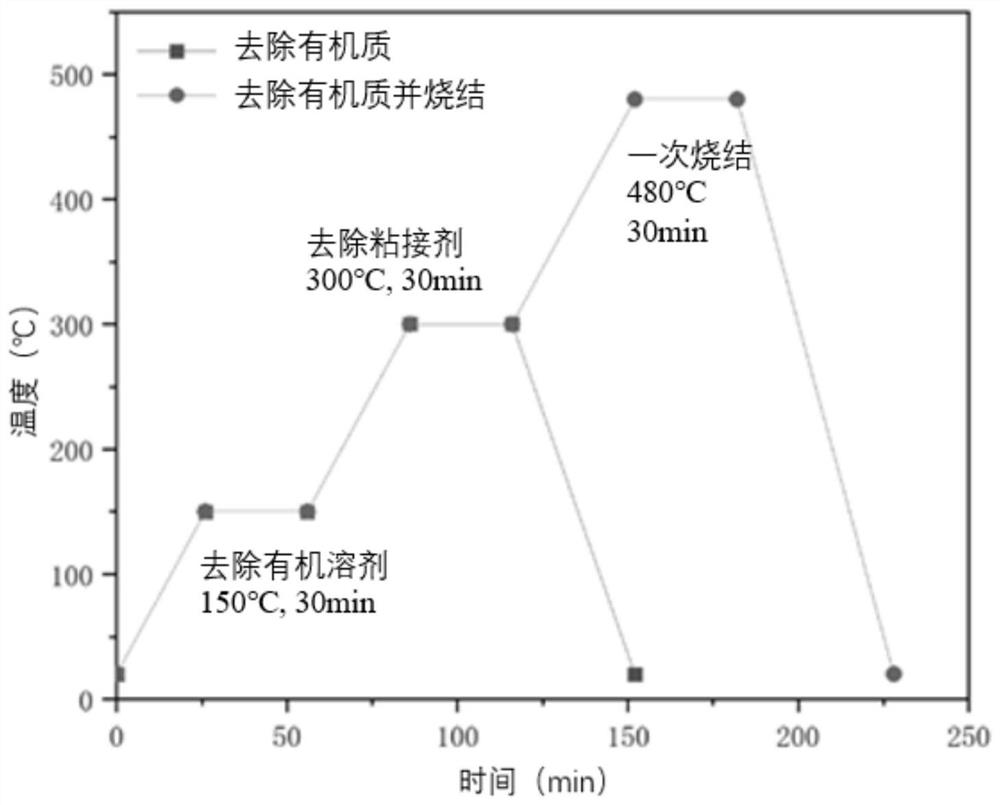

[0062] Step 3: The low-thickness glass frit coating is divided into two stages in the heating stage of the heating furnace. The heating furnace directly heats the coated glass substrate to 150 ° C in the air, keeps the temperature for 30 minutes, and removes the organic solvent; 300 ℃, heat preservation for 30min, remove the adhesive. The heating furnace heating curve is as figure 1 shown.

[0063] Step 4: Pull out the first pressing block 6, shrink the first cylinder 8, ...

Embodiment 2

[0065] The laser sintering method in this embodiment includes the following steps:

[0066] Step 1: ultrasonically clean the glass substrate with a mixture of distilled water and detergent.

[0067] Step 2: The glass paste is coated on the glass substrate by screen printing. Among them, the two screen plates used are screen printing plates with a film thickness of 25 μm. Screen printing pattern width 0.8mm. The final coating thickness is 8-10 μm, that is, a high-thickness glass frit coating is obtained.

[0068] Step 3: The high-thickness frit coating is divided into three stages during the heating stage in the furnace: organic solvent removal, binder removal and pre-sintering. heating curve such as figure 1 As shown in the figure, after removing the organic solvent and the binder, it was heated to 480 °C for 30 min, and then sintered.

[0069] Step 4: Pull out the first pressure plate 6, shrink the first cylinder 8, the second cylinder 11, the third cylinder 15, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com