Ultrasonic-assisted electric arc welding device

An arc welding and ultrasonic-assisted technology, which is applied in the direction of arc welding equipment, welding equipment, welding accessories, etc., can solve problems such as coarse joint structure grains, limited joint service performance, poor plastic toughness of joints, etc., to promote interaction and avoid High current and high-frequency high-voltage pulse damage and reduce the effect of weld porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Installation process

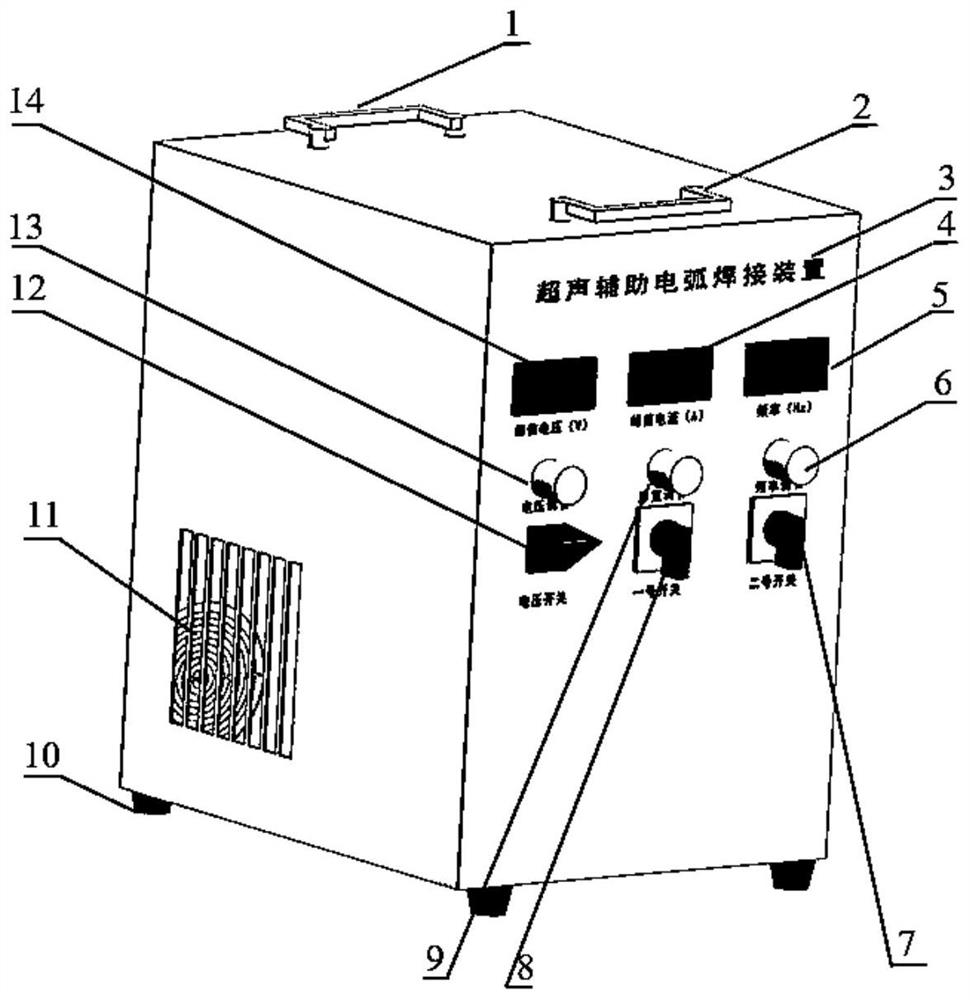

[0029] The ultrasonic-assisted arc welding device mainly includes an ultrasonic signal generator, an isolation coupling device, an automatic switch device, and a chassis body. The front side of the chassis body includes the ultrasonic signal peak current at the top, the ultrasonic signal peak voltage, and the ultrasonic signal frequency display. Ultrasonic signal voltage adjustment knob, ultrasonic signal current adjustment knob, ultrasonic signal pulse width adjustment knob, ultrasonic signal generator and automatic switching device power supply switch, ultrasonic signal frequency gear knob.

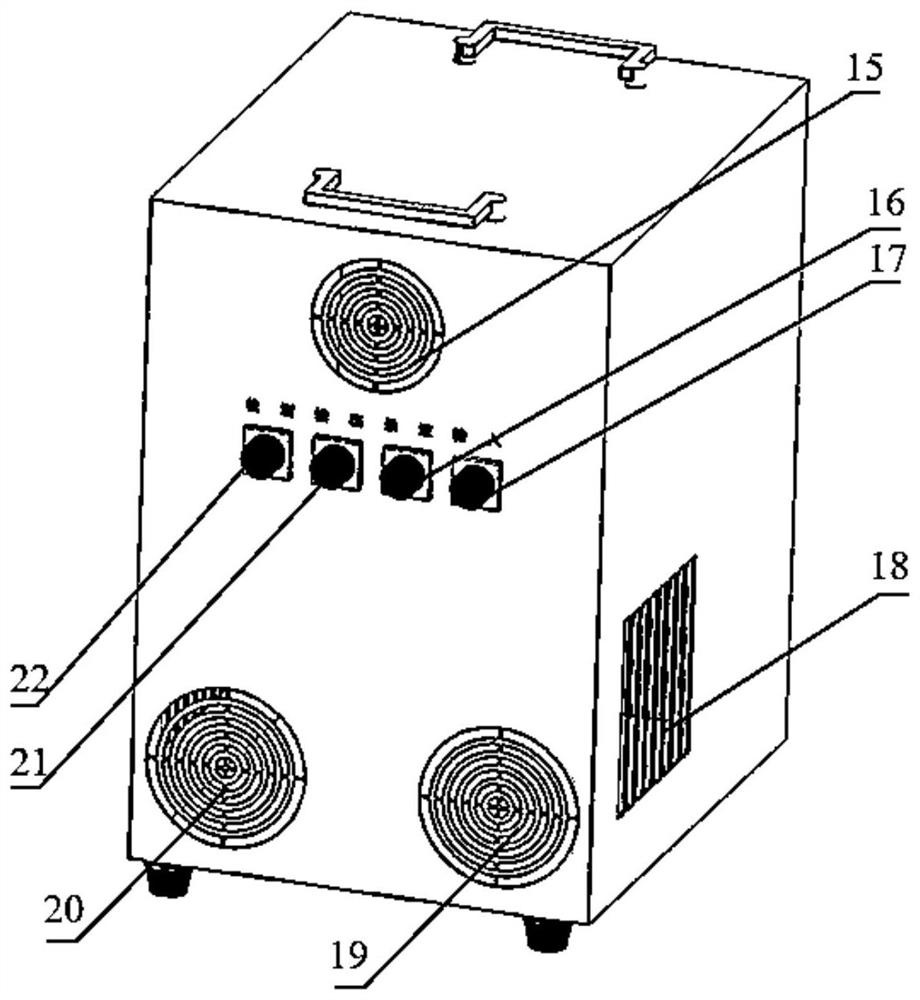

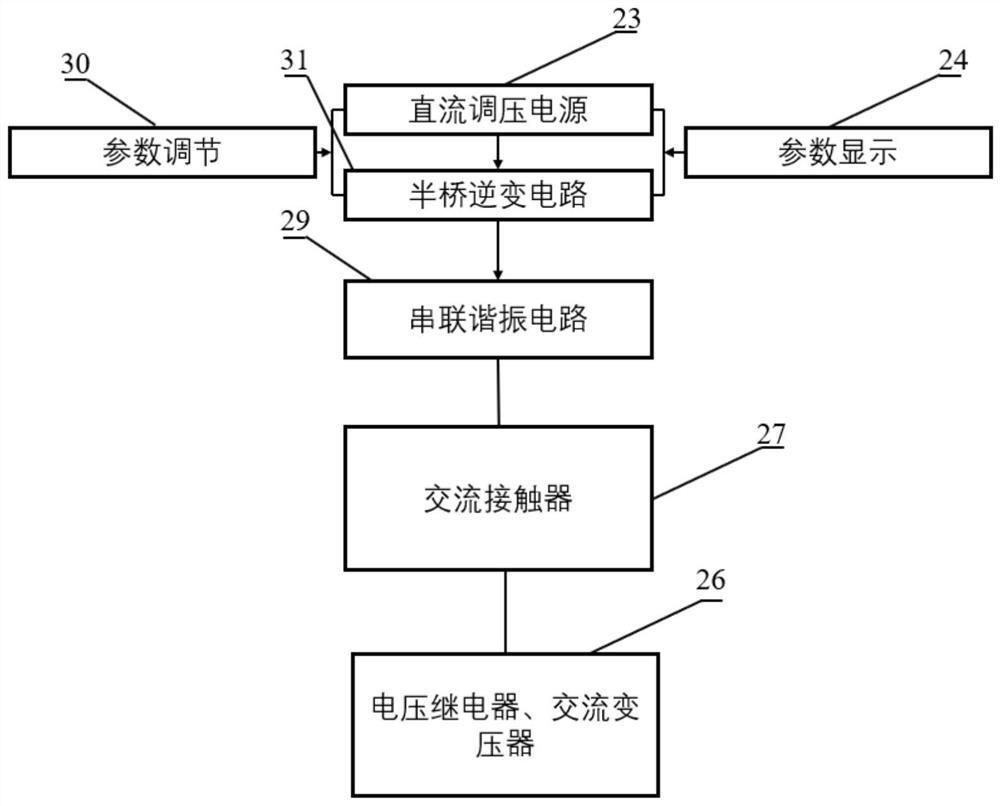

[0030] The invention provides an ultrasonic assisted arc welding device, which includes a chassis body 1, the first layer inside the chassis body 1 is an ultrasonic signal generator, the ultrasonic signal generator includes a DC voltage regulating power supply 23 and a half-bridge inverter circuit 31, and the ultrasonic auxiliary The arc welding device swit...

Embodiment 2

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0039] Installation process

[0040] The ultrasonic assisted arc welding device mainly includes an ultrasonic signal generator, an isolation coupling device, an automatic switch device, and a chassis body. The front side of the chassis body includes the peak current, peak voltage, and frequency Hz display at the top, and the voltage adjustment knob on the upper part of the front side of the chassis. Current adjustment knob, pulse width adjustment knob, ultrasonic signal generator and automatic switching device power supply switch, ultrasonic signal frequency gear knob.

[0041]The invention provides an ultrasonic assisted arc welding device, which includes a chassis body 1, the first layer inside the chassis body 1 is an ultrasonic signal generator, the ultrasonic signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com