Carbonate modified carbon nitride, preparation method thereof and application thereof in low-concentration ammonia-nitrogen wastewater treatment

A low-concentration ammonia nitrogen and wastewater treatment technology, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve problems such as unfavorable reuse, complex zeolite regeneration, small adsorption capacity, etc., to reduce energy The effect of consumption, simple preparation method, and excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

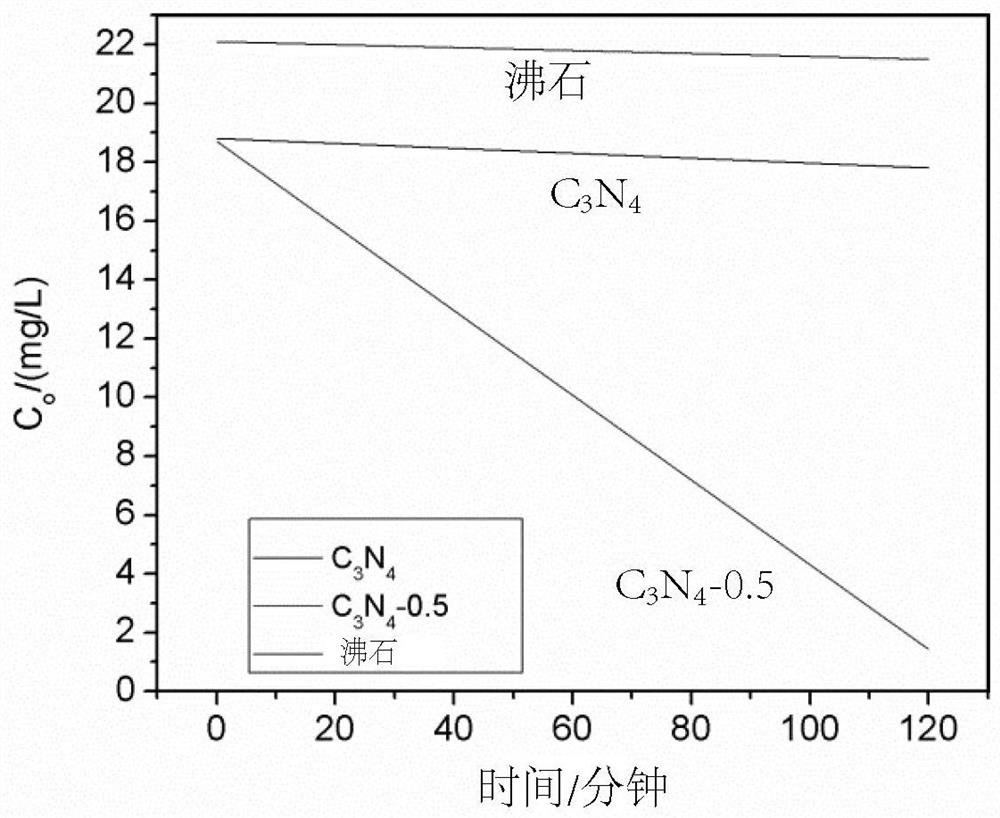

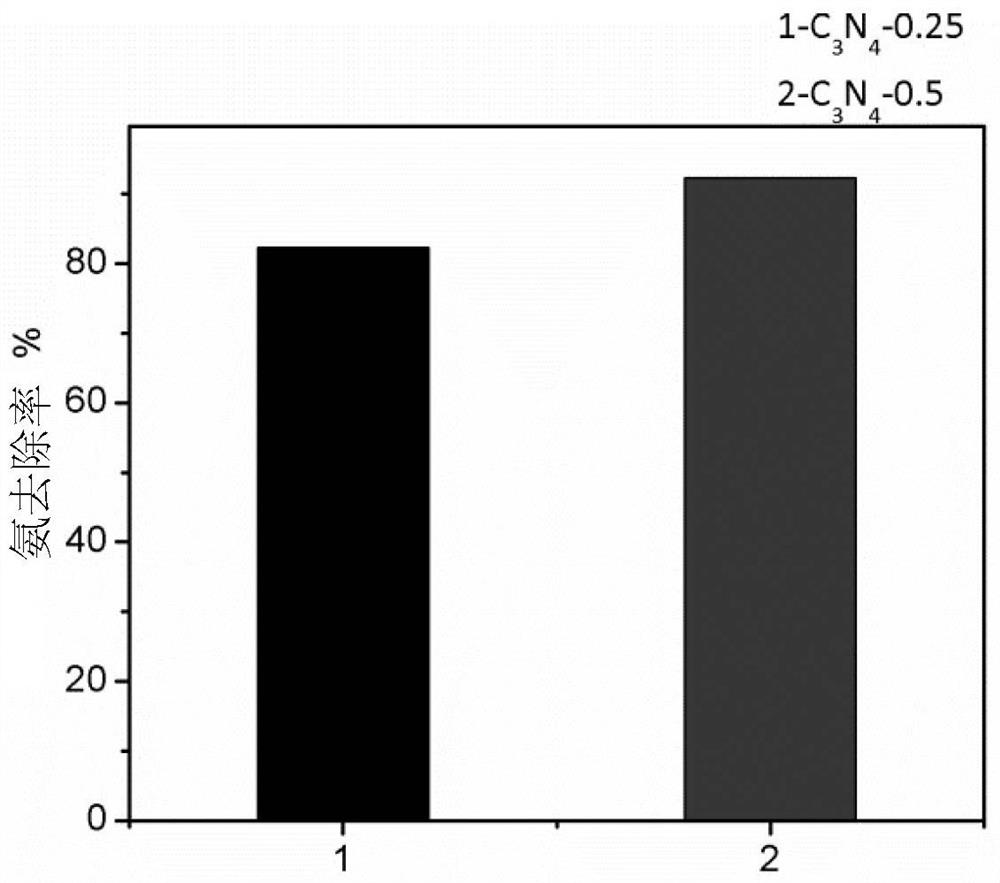

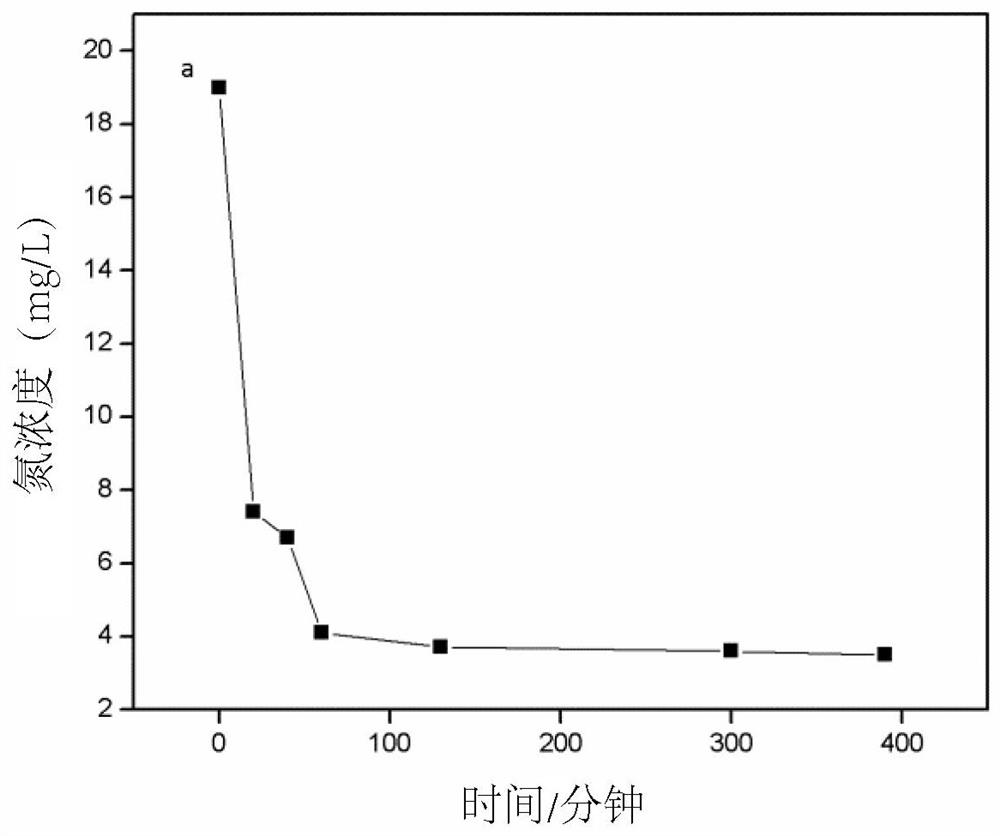

[0038] Weigh sodium bicarbonate and melamine (see Table 1) according to the molar ratio, and mix them uniformly, and transfer the mixture into a crucible and place it in a muffle furnace. Under the condition that the atmosphere is air, the temperature is raised to 520°C, the holding time is 4h, and naturally cooled to room temperature, the material is ground in a mortar, washed with deionized water until neutral, and the obtained powder is placed at 60°C Dry in a drying oven. The prepared sample (0.1g) was added to the solution containing 20mg / L NH 4 In the Cl solution, stir for 120min, and after standing for 20min, take the supernatant to measure the concentration of ammonia nitrogen, and the test results are listed in Table 1.

Embodiment 2

[0040] Take sodium bicarbonate and melamine (see table 1) according to mol ratio, and it is mixed homogeneously, and repeat the method for embodiment 1, only changed the mol ratio of carbonate and carbon nitride precursor, test result is in table 1 listed.

Embodiment 3

[0042] Weigh sodium carbonate and urea (see Table 1) according to the molar ratio, and mix it homogeneously, and repeat the method of Example 1, and the test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com