secondary battery

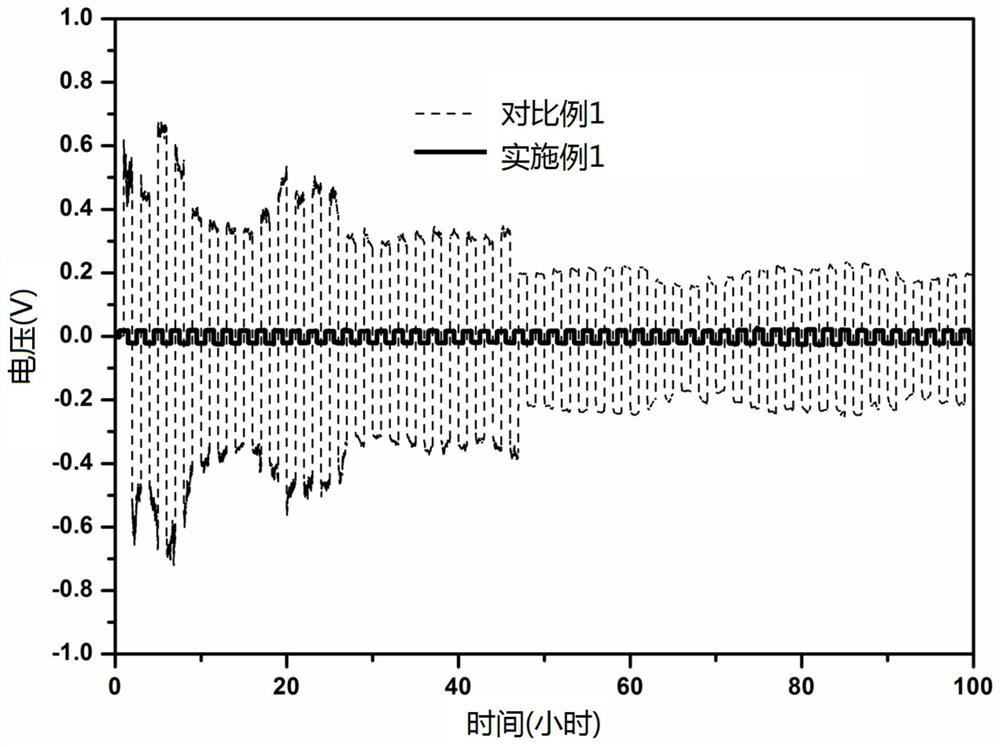

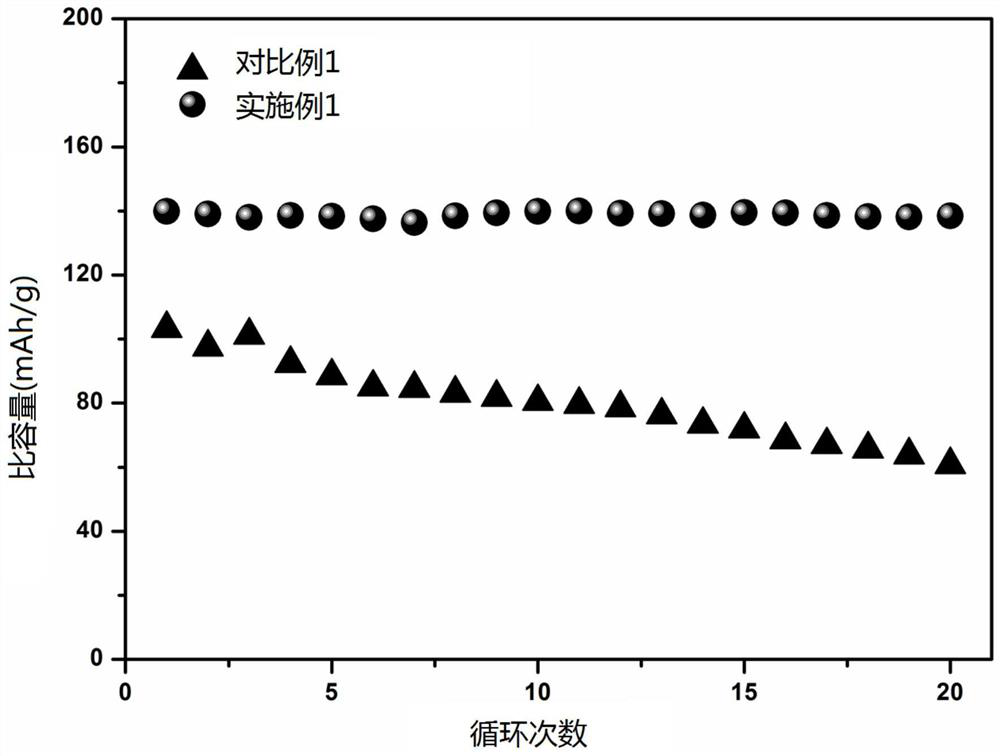

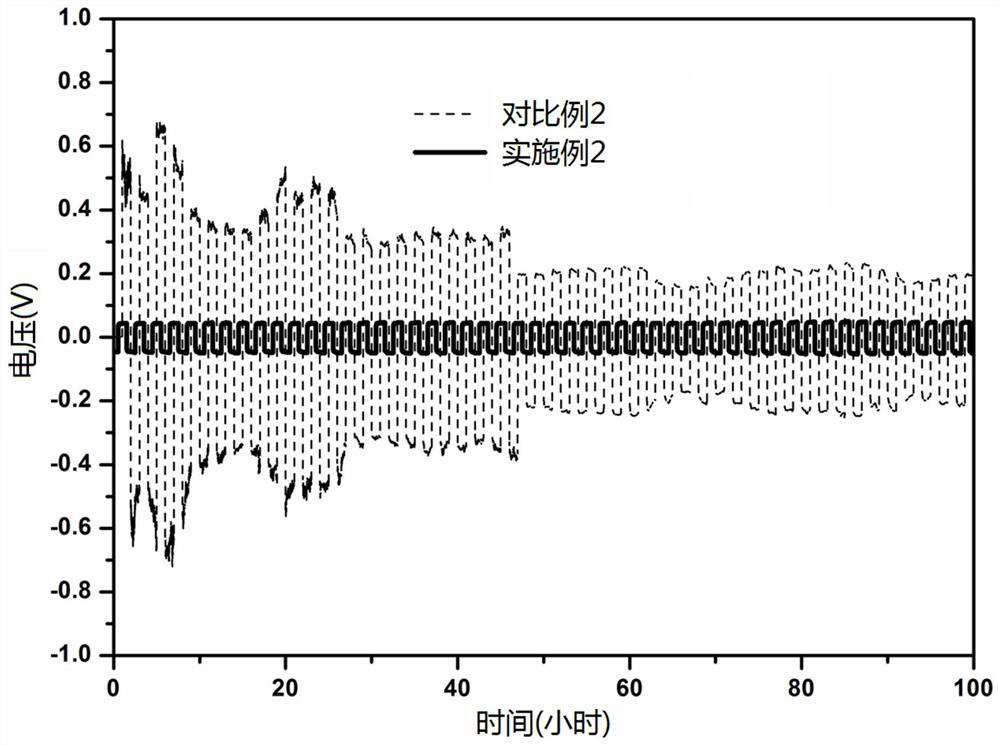

A secondary battery and electrolyte technology, which is applied in the direction of secondary batteries, lithium batteries, battery electrodes, etc., can solve the problems of rapid battery cycle attenuation, interface fracture, etc., and achieve improved interface compatibility, good contact, and improved cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of Li 7 La 3 Zr 2 o 12 (LLZO) particles

[0025] Will C 2 h 3 o 2 Li·2H 2 O, C 6 h 9 LaO 6 1.5H 2 O, C 8 h 12 o 8 Zr was weighed according to the molar ratio, dissolved in deionized water, and stirred ultrasonically for 1 hour. After the ultrasonic stirring was completed, the above solution was transferred to a polytetrafluoroethylene-lined stainless steel high-pressure reactor, and the reactor was placed in a dry box to heat up in a sealed manner. Heat to 80°C, keep warm for 12h, continue to heat up to 200°C, keep warm for 24h. After natural cooling, the hydrothermal product was taken out, and the hydrothermal product was centrifugally washed several times with deionized water and absolute ethanol respectively. After cleaning, it was dried at 120°C for 6 hours. After drying, the powder was calcined in a muffle furnace at 950°C for 12 hours. , and finally obtained Li with a particle size (D50) of 300nm 7 La 3 Zr 2 o 12 (LLZO) parti...

Embodiment 2

[0035] The core uses Li 6.4 Al 0.2 La 3 Zr 2 o 12 (Al-LLZO) particles, the outer shell is made of polymer PEO.

[0036] Specifically, with C 2 h 3 o 2 Li·2H 2 O, C 6 h 9 LaO 6 1.5H 2 O, C 8 h 12 o 8 Zr and Al(NO 3 ) 3 9H 2 O is raw material, prepares Li in the same manner as in Example 1 6.4 Al 0.2 La 3 Zr 2 o 12 (Al-LLZO) particles.

[0037] Add Al-LLZO and PEO into the beaker according to the mass ratio Al-LLZO:PEO=1:5, and prepare core-shell particles in the same manner as in Example 1.

[0038] Prepare the electrolyte and the modified layer in the same manner as in Example 1, and assemble the secondary battery.

Embodiment 3

[0040] The core uses Li 6.75 La 3 Zr 1.75 Nb 0.25 o 12 (Nb-LLZO) particles, the outer shell is made of poly 2-phenoxyethyl acrylate (EGPEA), and the solid electrolyte is made of Li 7 La 3 Zr 2 o 12 .

[0041] Specifically, with C 2 h 3 o 2 Li·2H 2 O, C 6 h 9 LaO 6 1.5H 2 O, C 8 h 12 o 8 Zr and niobium oxalate are raw materials, prepare Li in the same manner as in Example 1 6.75 La 3 Zr 1.75 Nb 0.25 o 12 (Nb-LLZO) particles.

[0042] Nb-LLZO and EGPEA were added into the beaker according to the mass ratio of Nb-LLZO:EGPEA=1:3, and core-shell particles were prepared in the same manner as in Example 1.

[0043] Prepare the electrolyte and the modified layer in the same manner as in Example 1, and assemble the secondary battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com