Treatment system and treatment method for preparing ammonium nitrate

A treatment system, ammonium nitrate technology, applied in ammonium nitrate fertilizer, water/sewage treatment, aerobic process treatment, etc., can solve problems such as retention, achieve stable effect, broad application prospects, and high reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

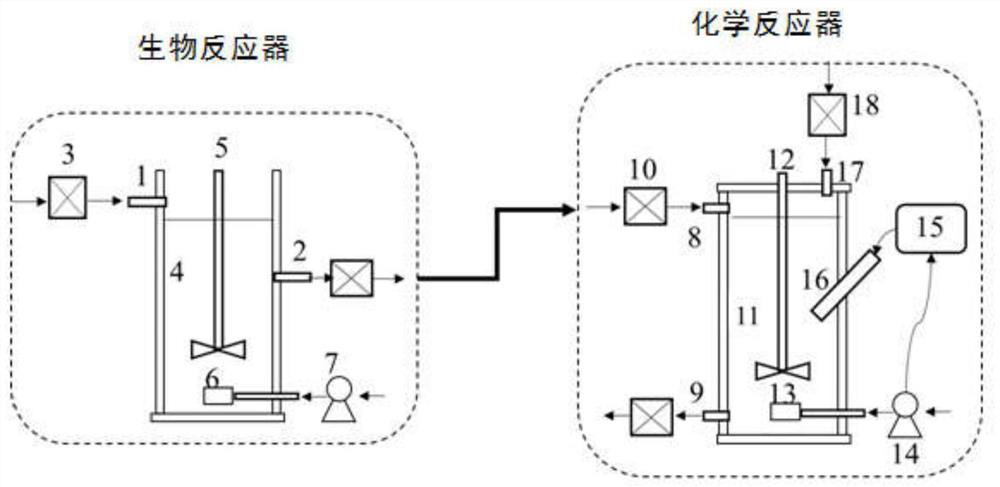

[0038] Such as figure 1 As shown, this embodiment provides a treatment system for preparing ammonium nitrate, including a bioreactor and a chemical reactor.

[0039] Wherein, the bioreactor is a sequence batch reactor (SBR) with a volume of 1.5L, including a water inlet 1, a water outlet 2, a peristaltic pump 3, a reaction chamber 4, a stirring paddle 5, a first aeration head 6 and The first aeration device 7 is provided with a peristaltic pump 3 at the water inlet 1 and the water outlet 2 . The reaction chamber 4 includes activated sludge inoculated with nitrosating bacteria, and the first aeration device 7 provides biological nitrosation reaction in the reaction chamber 4 through the first aeration head 6 arranged at the bottom of the reaction chamber 4. Oxygen, the stirring paddle 5 makes the activated sludge fully mix and contact with the wastewater containing ammonia nitrogen.

[0040] Among them, the chemical reactor includes a water inlet 8, a water outlet 9, a peristal...

Embodiment 2

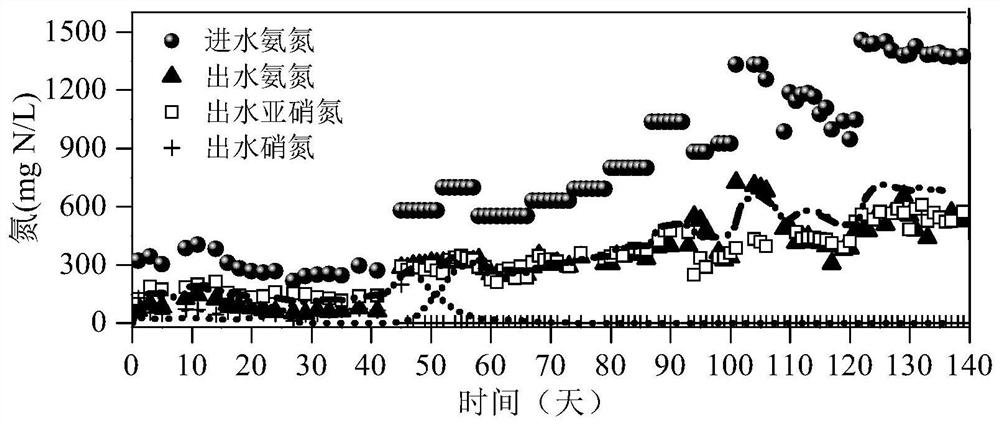

[0043] The present embodiment provides a kind of method that adopts the processing system of embodiment 1 to prepare ammonium nitrate, and wherein feed is the urine that stays in storage pond for 3 days, specifically as follows:

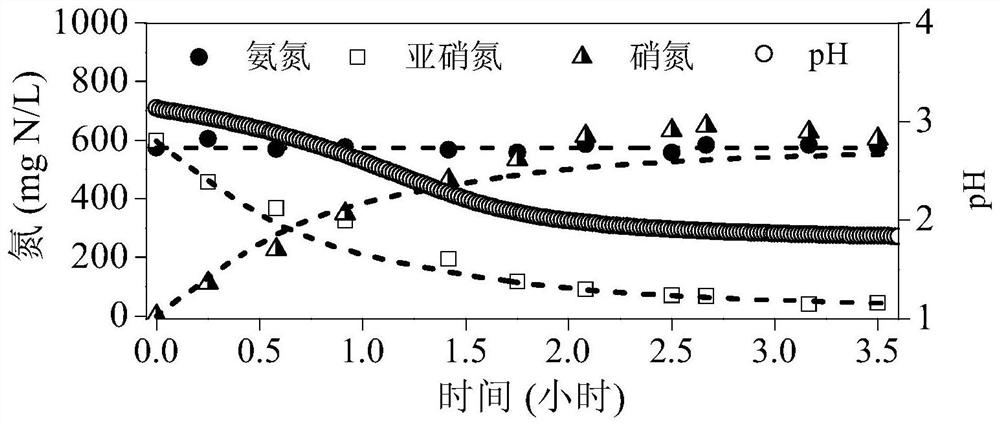

[0044] Firstly, the urine is pumped into the reaction chamber of the SRB, aerated (dissolved oxygen concentration does not need to be controlled), so that the ammonia nitrogen in the urine undergoes a biological nitrosation reaction, and the residence time is 1 day, and then the effluent of the SBR (at this time The ratio of ammonia nitrogen to nitrite nitrogen is 1:1) pumped into the closed reaction chamber of the chemical reactor, and the initial pH of the solution is 3 by adding 1:9 hydrochloric acid (the concentration of free nitrous acid in the solution at this time is about 240HNO 2 -N / L), use dissolved oxygen electrodes and dissolved oxygen controllers to control pure oxygen intermittent aeration, so that the dissolved oxygen concentration in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com