A kind of paper-based filter material base paper that replaces mask melt-blown cloth and preparation method thereof

A technology of filter material and melt-blown cloth, which is applied to the paper-based filter material base paper and its preparation field to replace the melt-blown cloth of masks, can solve the problem of environmental pollution, low output of polypropylene melt-blown cloth, plant fiber and polylactic acid fiber into paper Problems such as large aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

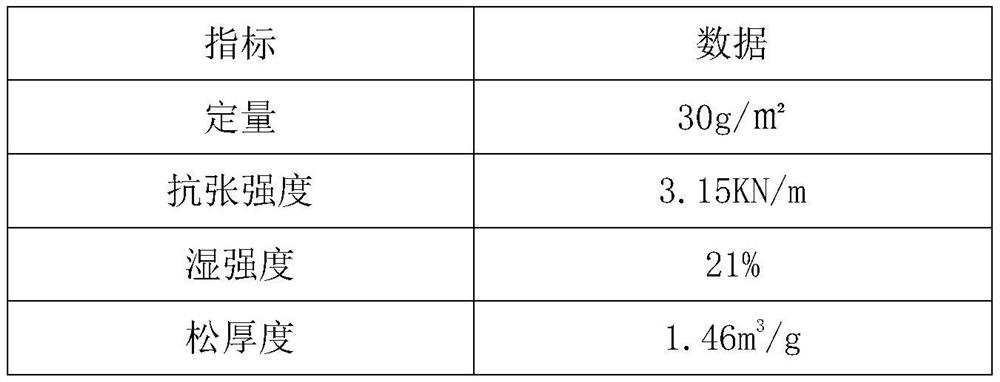

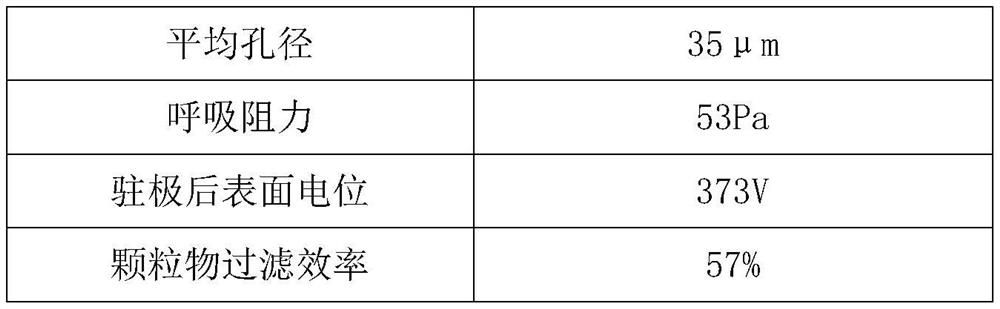

Embodiment 1

[0072] A kind of paper-based filter material raw paper that replaces mask melt-blown cloth and preparation method thereof, the steps are as follows:

[0073] (1) Mix the polylactic acid fiber accounting for 30% of the total fiber mass ratio with the softwood fiber with a beating degree of 30°SR accounting for 70% of the total fiber mass ratio, and add 0.5% of the total fiber mass as a papermaking wet strength agent polyamide Ammonia epichlorohydrin, and disperse evenly, make slurry;

[0074] (2) After diluting the slurry prepared in step (1) to a concentration of 0.025%, the paper machine is loaded, and the paper is formed by inclined wire forming to obtain a wet paper web;

[0075] (3) to the wet paper web surface that step (2) makes the negative ion fiber coating that above-mentioned making is sprayed, sprays upper surface, and spray amount is 3.5g / m in terms of solids 2 , and then according to the drying process of 30g / ㎡ sanitary napkin base paper and the subsequent paper-...

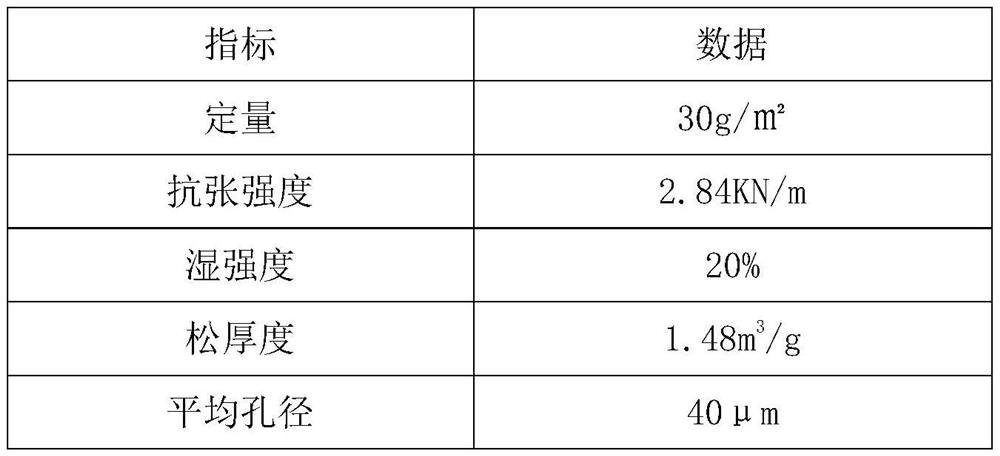

Embodiment 2

[0080] A kind of paper-based filter material raw paper that replaces mask melt-blown cloth and preparation method thereof, the steps are as follows:

[0081] (1) The polylactic acid fiber accounting for 40% of the total fiber mass ratio and the coniferous wood fiber with a beating degree of 30°SR accounting for 60% of the total fiber mass ratio are mixed, and 0.5% of the total fiber mass is added. Ammonia epichlorohydrin, and disperse evenly, make slurry;

[0082] (2) After diluting the slurry prepared in step (1) to a concentration of 0.025%, the paper machine is loaded, and the paper is formed by inclined wire forming to obtain a wet paper web;

[0083] (3) spray the negative ion fiber coating that embodiment 1 makes to the wet paper web surface that step (2) makes, spray the upper surface, and the spray amount is 3.5g / m in terms of solids 2 , and then according to the drying process of 30g / ㎡ sanitary napkin base paper and the subsequent paper-making process, the paper-base...

Embodiment 3

[0088]A kind of paper-based filter material raw paper that replaces mask melt-blown cloth and preparation method thereof, the steps are as follows:

[0089] (1) The polylactic acid fiber accounting for 20% of the total fiber mass ratio and the coniferous wood fiber accounting for 80% of the total fiber mass ratio with a beating degree of 30 ° SR are mixed, and 0.5% of the total fiber mass is added. Ammonia epichlorohydrin, and disperse evenly, make slurry;

[0090] (2) After diluting the slurry prepared in step (1) to a concentration of 0.025%, the paper machine is loaded, and the paper is formed by inclined wire forming to obtain a wet paper web;

[0091] (3) spray the negative ion fiber coating that embodiment 1 makes to the wet paper web surface that step (2) makes, spray the upper surface, and the spray amount is 3.5g / m in terms of solids 2 , and then according to the drying process of 30g / ㎡ sanitary napkin base paper and the subsequent paper-making process, the paper-bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com