Polyurethane coating and preparation method thereof

A polyurethane coating and polyurethane emulsion technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of waste of energy consumption, non-compliance with national environmental protection indicators, easy to sag, etc., to solve the problem of excessive voc and ensure excellent quality. performance, the effect of improving anti-settling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

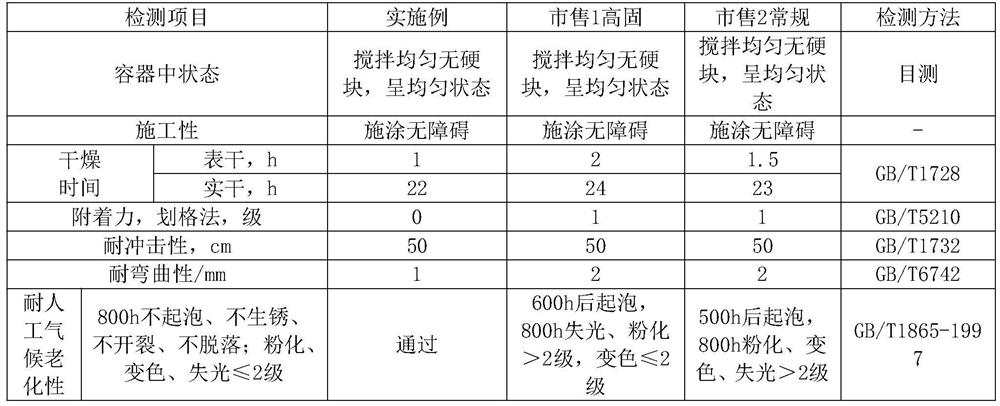

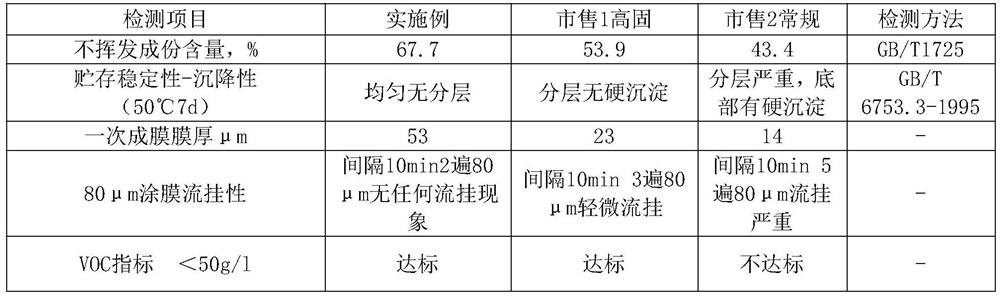

Examples

Embodiment

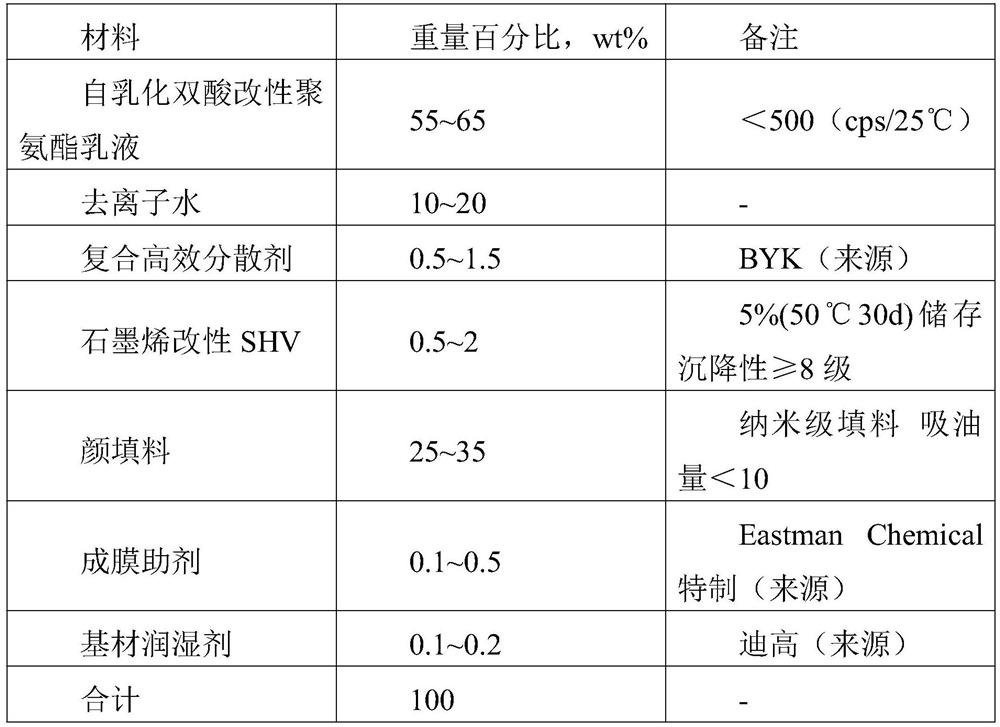

[0030] Polyurethane coating of the present invention comprises following composition by mass fraction:

[0031]

[0032] A kind of preparation method of polyurethane coating of the present invention, it comprises the following steps:

[0033] (1) 268.8g water is added to the reactor;

[0034] (2) Start the mixer, the mixer speed is 500 rpm, add 32g composite high-efficiency dispersant, 20g graphene modified SHV, and stir evenly;

[0035] (3) 800g of rutile titanium dioxide and 400g of nanoscale filler powder were dropped into, stirred at 1500 rpm, and the stirring time was 60 minutes;

[0036] (4) Reduce the rotating speed of the mixer, brush the tank with 36.6g deionized water; then pass through the grinder, grind twice, and the fineness reaches 18 μm; grind into the batching tank for the last time;

[0037] (5) 2400g self-emulsifying bis-acid modified polyurethane emulsion is dropped into the batching tank and mixed evenly with the ground slurry; the mixer speed is 500 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com