Mechanochromic high-toughness nylon 6 and its preparation method

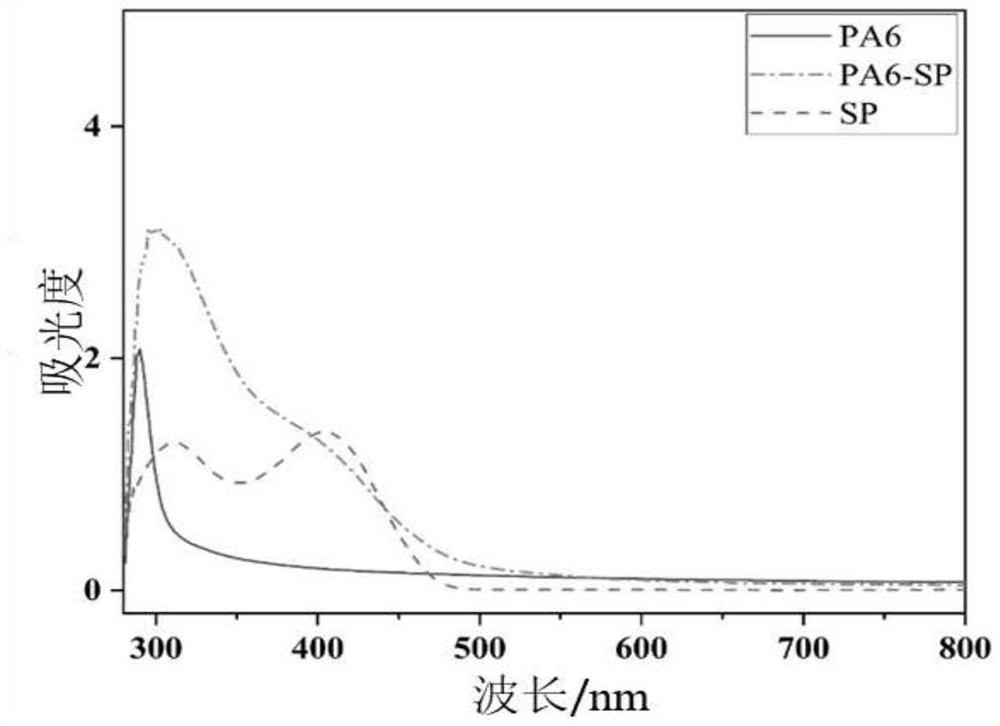

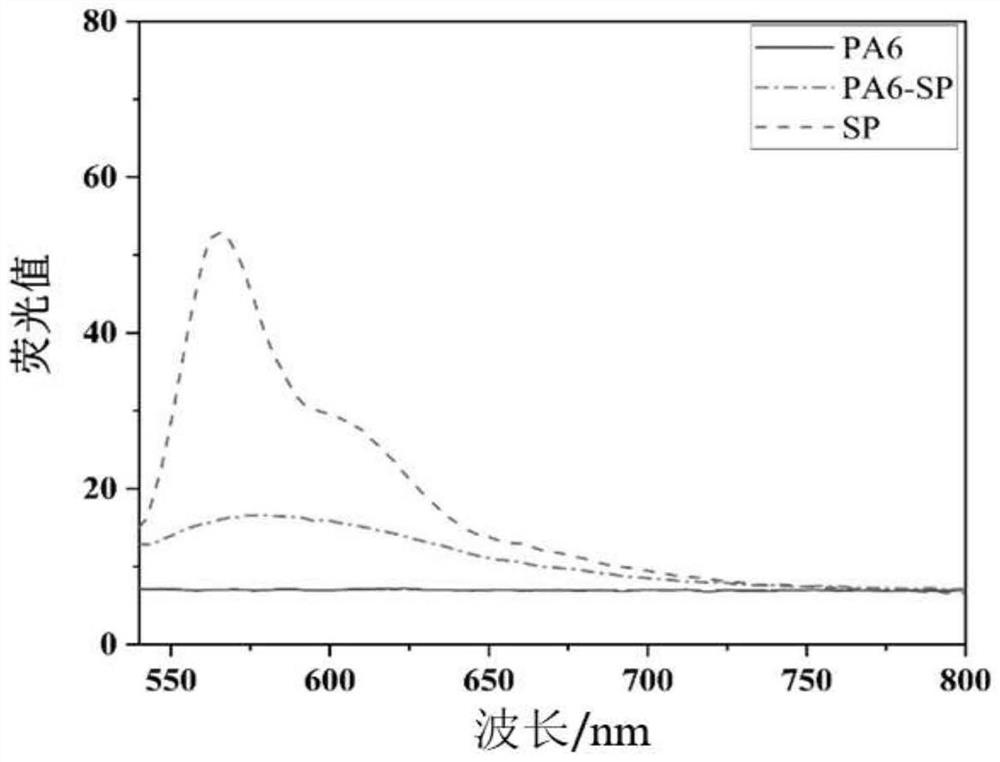

A technology that causes color change and high toughness. It is applied in the field of mechanochromic high toughness nylon 6 and its preparation. It can solve the problems of discoloration of spiropyran, poor impact resistance and low toughness, and achieve improved effectiveness, high response sensitivity, Effects of Reliability and Sensitivity Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

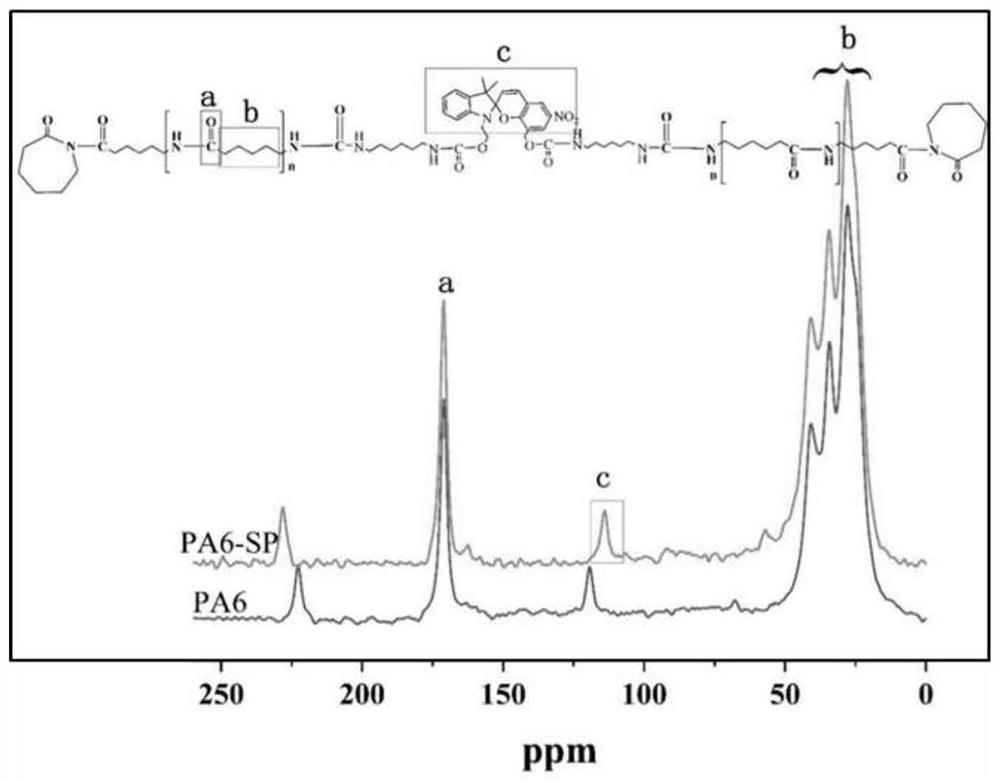

[0032] The preparation method of the mechanochromic high-toughness nylon 6 provided by the invention comprises the following steps:

[0033] S1. Polymerize diisocyanate with a molar ratio of 1.1:1 to 1.3:1 and polyether diol at 80 to 90° C. After reacting for 2 to 4 hours, an isocyanate-terminated polyurethane prepolymer is prepared. The process is as follows:

[0034]

[0035] Wherein R is one or more of hexamethylene, diphenylmethane, and methanephenyl, and R' is one or more of polyethylene glycol, polypropylene glycol, and polytetramethylene glycol.

[0036]The key point of this step is that the diisocyanate needs to be in excess to ensure that the end groups are isocyanate groups. By adjusting the reaction temperature and reaction time, the molecular weight and purity of the isocyanate-terminated polyurethane prepolymers are controlled to prepare different Lizhi Nylon 6 with color change responsive properties.

[0037] S2. Add the isocyanate-terminated polyurethane pr...

Embodiment 1

[0044] The mechanochromic high-toughness nylon 6 provided in Example 1 is prepared through the following steps:

[0045] S1. Preparation of isocyanate-terminated polyurethane prepolymer: According to n(NCO):n(OH)=1.2:1, weigh toluene diisocyanate and polypropylene glycol respectively, add polypropylene glycol into a three-necked flask, and heat at 110°C After drying under reduced pressure for 2 hours, lower the reaction temperature to 85° C., add toluene diisocyanate, and react at constant temperature for 3 hours to obtain an isocyanato-terminated polyurethane prepolymer with a molecular weight of 1800 g / mol.

[0046] S2. Preparation of isocyanato-terminated spiropyran derivatives: according to n(NCO):n(OH)=1.2:1, respectively weigh the isocyanato-terminated polyurethane prepolymer and dihydroxy spiropyran, and It was placed in a reaction flask, and then the catalyst dibutyltin dilaurate (DBTDL) was added into the reaction flask, and stirred at 85° C. for 2 h to obtain an isoc...

Embodiment 2~5

[0052] Compared with Example 1, the mechanochromic high-toughness nylon 6 provided in Examples 2-5 differs in that the preparation conditions in Step S1 and the molecular weight of the isocyanato-terminated polyurethane prepolymer are shown in Table 1 , and others are substantially the same as those in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com