Multi-source solid waste-based grouting cementing material as well as preparation method and application thereof

A cementitious material and grouting technology, applied in the field of multi-source solid waste-based grouting cementitious materials and their preparation, can solve the problem of poor corrosion resistance, less than 1% utilization rate of red mud, and setting time of grouting cementitious materials. It can meet the needs of engineering applications, solve the problem of solid waste storage, and improve the comprehensive utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

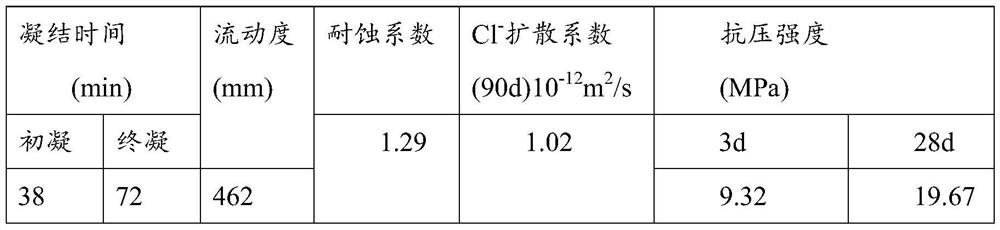

Embodiment 1

[0046] 1. Components and mass ratio: 60 parts of Bayer process red mud, 70 parts of other solid waste, 55 parts of activator, and 20 parts of admixture. Other solid wastes include the following raw materials in parts by weight: 20 parts of coal-fired slag, 20 parts of casting pig iron slag, 15 parts of converter steel slag, and 15 parts of desulfurized gypsum. Activator components and mass ratios are 34 parts of sodium hydroxide aqueous solution with a concentration of 12%, 22 parts of water glass, 18 parts of calcium chloride and 40 parts of sulphoaluminate cement clinker. The additive components and mass ratio are 8 parts of calcium formate, 22 parts of superfine silica fume, 8 parts of magnesium oxide expansion agent, and 6 parts of naphthalene-based water reducer.

[0047] 2. Preparation method: Use a ball mill to grind the red mud to a specific surface area of 500m 2 / Kg, grind the slag to a specific surface area of 450m 2 / Kg, grind the steel slag to a specific sur...

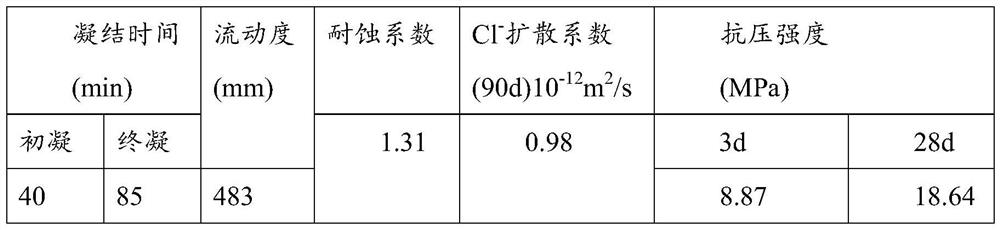

Embodiment 2

[0051] 1. Components and mass ratio: 80 parts of Bayer red mud, 70 parts of other solid waste, 60 parts of activator, 20 parts of admixture; other solid waste contains the following raw materials by weight; 20 parts of coal-fired slag, steelmaking pig iron 20 parts of slag, 15 parts of open hearth steel slag, 15 parts of desulfurized gypsum; 35 parts of activator components and mass ratio of 15% sodium hydroxide aqueous solution, 25 parts of water glass, 18 parts of calcium chloride, ordinary portland cement 45 servings. The components and mass ratio of the admixture are 8 parts of dimethyltriisopropanolamine, 30 parts of superfine magnesium oxide, 12 parts of iron filing expansion agent, and 6 parts of polycarboxylate superplasticizer.

[0052] 2. Preparation method: Use a ball mill to grind the red mud to a specific surface area of 450m 2 / Kg, grind the slag to a specific surface area of 400m 2 / Kg, grind the steel slag to a specific surface area of 350m 2 / Kg, grin...

Embodiment 3

[0056] 1. Components and mass ratio: 60 parts of sintering red mud, 60 parts of other solid waste, 40 parts of activator, and 10 parts of admixture. Other solid wastes include the following raw materials in parts by weight: 25 parts of coal-fired slag, 15 parts of special pig iron slag, 12 parts of electric furnace steel slag, and 8 parts of desulfurized gypsum. Activator components and mass ratios are 28 parts of 10% sodium hydroxide aqueous solution, 12 parts of water glass, 10 parts of calcium chloride and 30 parts of aluminate cement clinker. The additive components and mass ratio are 4 parts of triethanolamine, 15 parts of ultra-fine zeolite powder, 7 parts of calcium sulfoaluminate expansion agent, and 2 parts of naphthalene-based water reducer.

[0057] 2. Preparation method: Use a ball mill to grind the red mud to a specific surface area of 500m 2 / Kg, grind the slag to a specific surface area of 450m 2 / Kg, grind the steel slag to a specific surface area of 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com