Unmanned rapid cleaning system for airport oil tank

A cleaning system and oil tank technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, grease/oily substances/floating matter removal devices, etc., which can solve the problem of excessive land occupation, complex system composition, and failure to achieve standard discharge of sewage and other problems to achieve the effect of ensuring safe operation and solving non-recyclable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

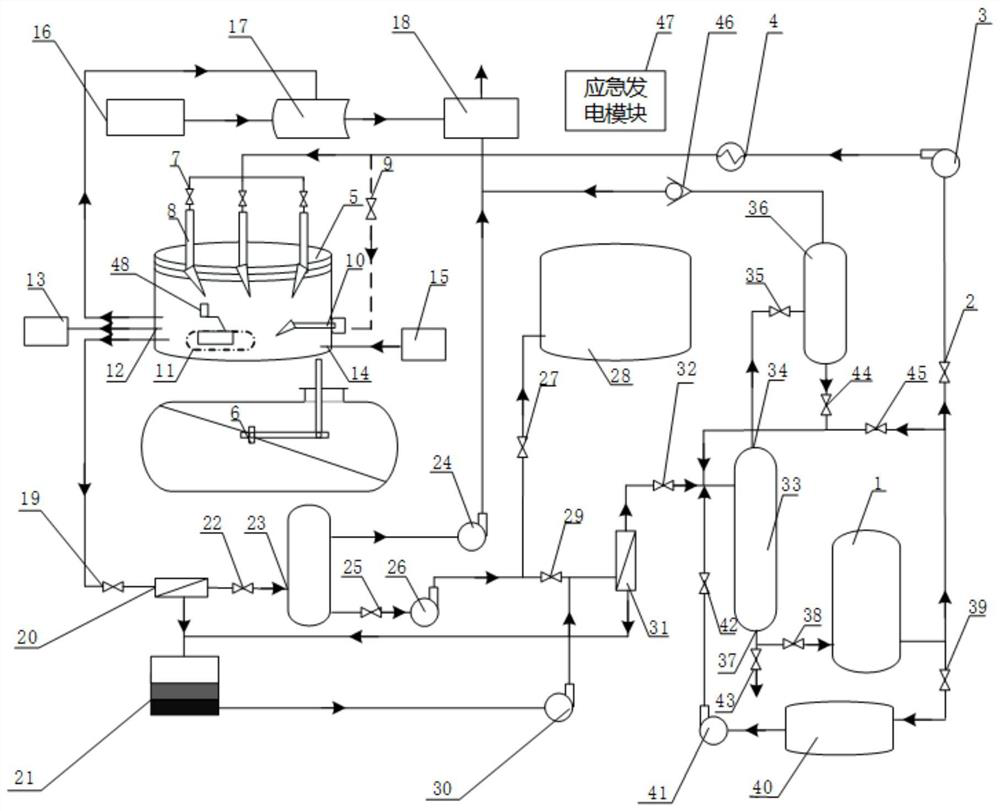

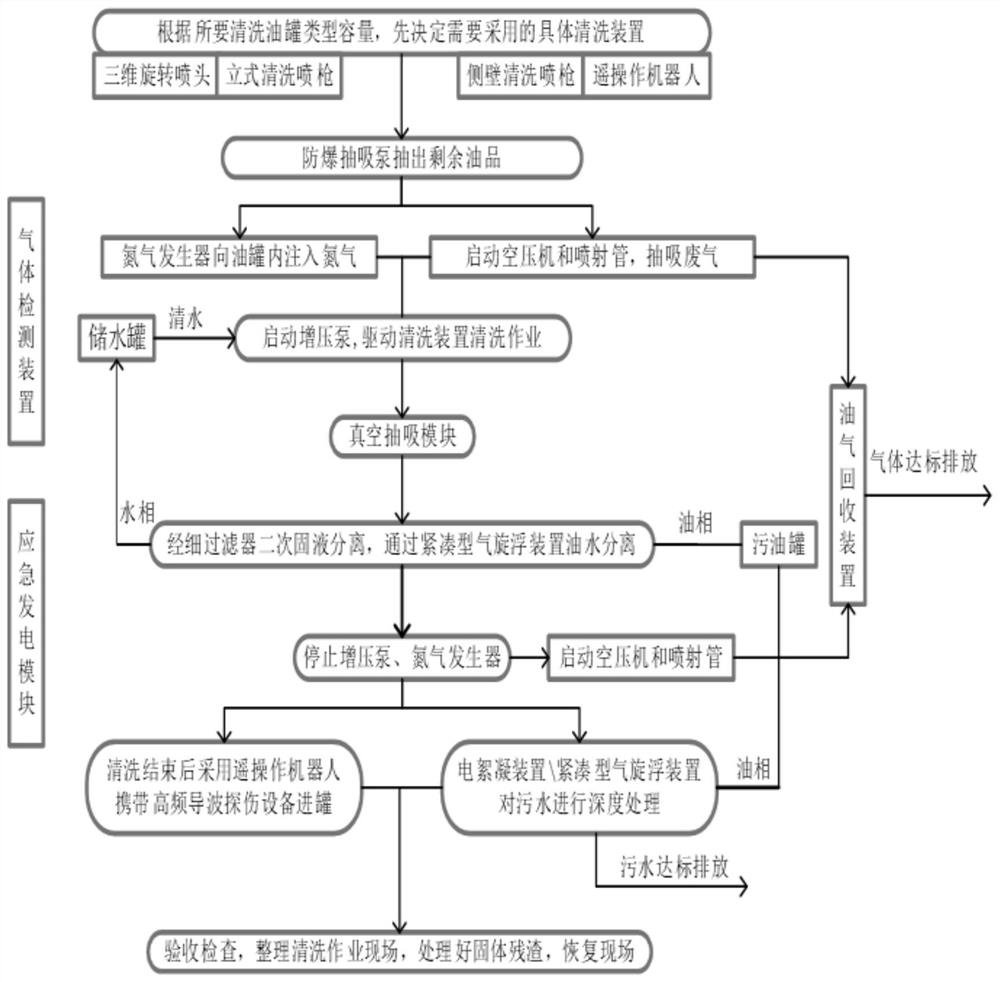

[0053] refer to figure 1 , an airport unmanned rapid cleaning system provided by the present invention, comprising: a cleaning module, a gas detection module, a nitrogen generation module, a vacuum suction module, an oil-water separation and reuse module, a sewage discharge treatment module meeting standards, an oil gas recovery treatment module, and a non-destructive Detection module and emergency power generation module.

[0054] The cleaning module includes a water storage tank 1 connected through a clean water pipeline, a booster pump 3, a heater 4, and cleaning equipment. The cleaning equipment includes a small three-dimensional rotary nozzle 6 for cleaning the soil-covered tank, and a vertical spray nozzle for cleaning the vault tank. Spray gun 8, side wall spray gun 10 for cleaning oil tanks in caverns or built-in roof oil tanks, and remote operation robot 11 for cleaning and non-destructive testing of large internal floating roof oil storage tanks; valve 2 is opened, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com