A Control Method of Active Clamp Flyback Converter

A flyback converter and control method technology, applied in control/regulation systems, DC power input conversion into DC power output, instruments, etc., can solve the problem of clamping capacitor energy not being released, etc., to achieve high light load efficiency, The effect of low no-load power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In one embodiment, the active clamp flyback converter is used to regulate the input voltage and output a desired voltage, the active clamp flyback converter includes a main switch tube for controlling the current magnitude of the primary winding of the flyback transformer, and A clamp switch tube that clamps the node voltage on the primary side of the flyback transformer. The controller generates control signals for controlling the main switch and the clamp switch by detecting a feedback (FB) voltage.

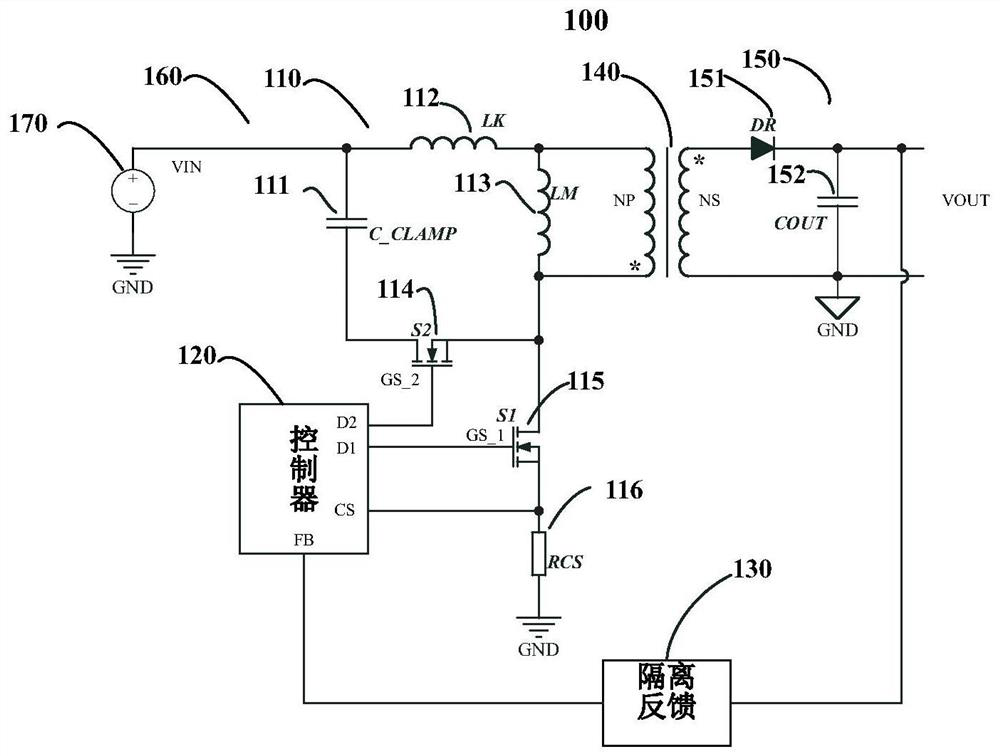

[0025] figure 1 An active clamp flyback power supply 100 according to some embodiments is presented in schematic form. Wherein 100 includes an active clamp flyback (ACF) converter 160 and a controller 120 for adjusting the input voltage of the voltage source 170 and outputting a desired output voltage V out .

[0026] The ACF converter 160 includes a primary side circuit 110 , a flyback transformer 140 , and a secondary side circuit 150 . Both the primary winding and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com