Environment-friendly VOCs low-temperature combustion catalyst and preparation method thereof

An environmentally friendly, low-temperature combustion technology, applied in the field of resources and the environment, can solve problems such as poisoning and deactivation, chlorine poisoning catalysts, etc., and achieve the effects of enhancing reactivity, inhibiting erosion, and strengthening interactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

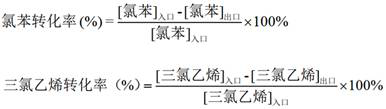

Image

Examples

Embodiment 1

[0027] A preparation method of an environment-friendly VOCs low-temperature combustion catalyst is realized through the following specific steps:

[0028] (1) Preparation of mesoporous cerium-manganese composite oxides

[0029] Stir and mix the cerium nitrate solution and the manganese acetate solution at room temperature for 10 minutes, add urea and CTAB and continue to stir for 25 minutes, then treat the resulting mixed solution at 85°C for 24 hours, successively centrifuge, wash, dry, and then roast at 350°C 4h obtains mesoporous cerium-manganese composite oxide; the ratio of the amount of matter of said cerium nitrate and manganese acetate is 0.25:1, the addition of said urea is 10 times of the amount of total matter of cerium nitrate and manganese acetate, and said CTAB The addition of is the 5wt% of cerium nitrate and manganese acetate gross mass;

[0030] (2) Preparation of composite carrier

[0031] 1) Synthesis of ionic liquid precursor PyPS

[0032]Add 1,3-propane...

Embodiment 2

[0038] A preparation method of an environment-friendly VOCs low-temperature combustion catalyst is realized through the following specific steps:

[0039] (1) Preparation of mesoporous cerium-manganese composite oxides

[0040] Stir and mix the cerium nitrate solution and manganese acetate solution at room temperature for 15 minutes, add urea and CTAB and continue to stir for 30 minutes, then treat the resulting mixed solution at 90°C for 18 hours, centrifuge, wash, and dry in sequence, and then roast at 400°C 3h obtains mesoporous cerium-manganese composite oxide; the ratio of the amount of matter of the cerium nitrate and manganese acetate is 1:1, the addition of the urea is 15 times of the total amount of matter of the cerium nitrate and manganese acetate, and the CTAB The addition of is 7 wt% of cerium nitrate and manganese acetate gross mass;

[0041] (2) Preparation of composite carrier

[0042] 1) Synthesis of ionic liquid precursor PyPS

[0043] Add 1,3-propane sult...

Embodiment 3

[0049] A preparation method of an environment-friendly VOCs low-temperature combustion catalyst is realized through the following specific steps:

[0050] (1) Preparation of mesoporous cerium-manganese composite oxides

[0051] Stir and mix the cerium nitrate solution and the manganese acetate solution at room temperature for 20 minutes, add urea and CTAB and continue to stir for 35 minutes, then treat the resulting mixed solution at 95°C for 12 hours, successively centrifuge, wash, dry, and then roast at 450°C 2h obtains mesoporous cerium-manganese composite oxide; the ratio of the amount of matter of said cerium nitrate and manganese acetate is 4:1, the addition of said urea is 20 times of the amount of total matter of cerium nitrate and manganese acetate, and said CTAB The add-on is 9wt% of the total mass of cerium nitrate and manganese acetate;

[0052] (2) Preparation of composite carrier

[0053] 1) Synthesis of ionic liquid precursor PyPS

[0054] Add 1,3-propane sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com