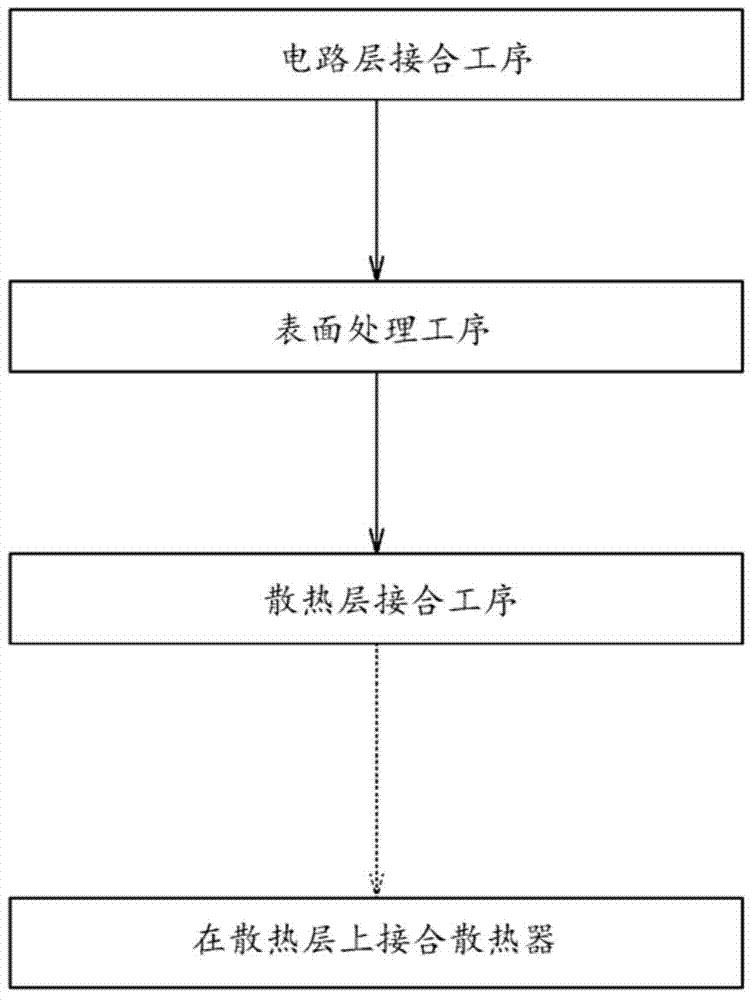

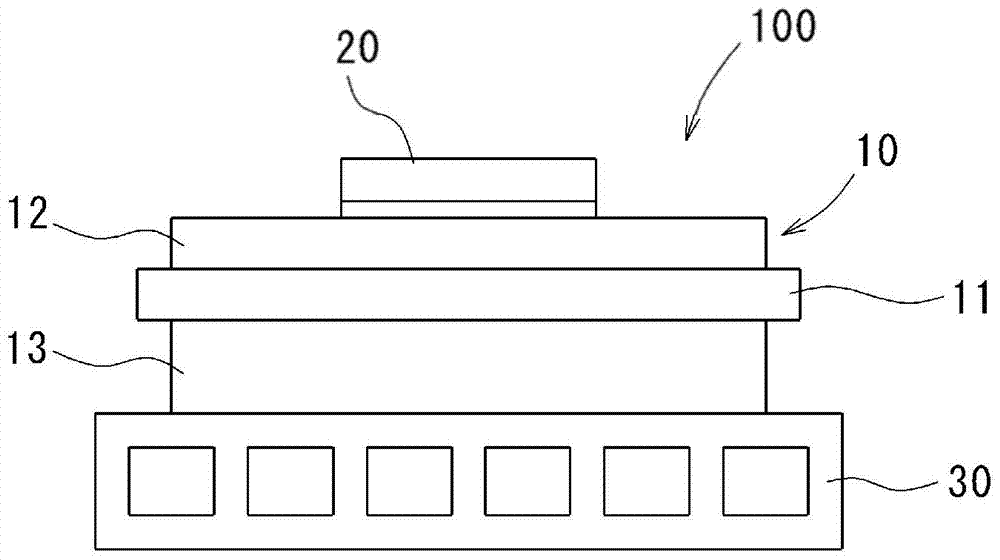

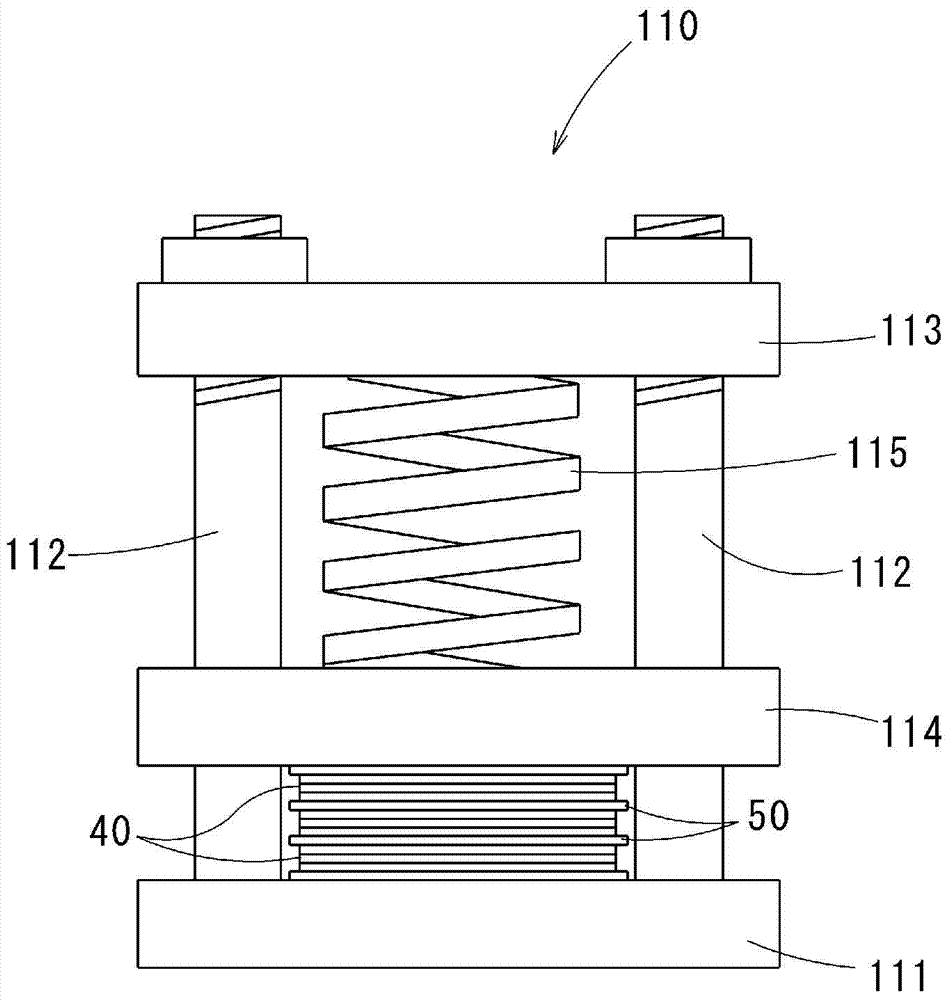

Method for producing substrate for power modules

A technology of a power module and a manufacturing method, which is applied in the field of manufacturing substrates for power modules, can solve problems such as increased peeling of the bonding interface between a ceramic substrate and a heat dissipation layer, and achieve the effects of high bonding reliability and corrosion inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0043] Example

[0044] In order to confirm the effect of the manufacturing method by the power module board|substrate demonstrated above, the experiment was performed.

[0045] First, ceramic substrates made of AlN of 30 mm square were prepared as samples a to g. Among them, the ceramic substrates of the samples b to g were subjected to heat treatment at 860° C. for 30 minutes, assuming that they were bonded by active metal brazing. Then, among the samples b to g to which the heat treatment was applied, the samples c to g were surface-treated with an acid as described below. The thickness of each oxide film in the samples a to g after each treatment was measured.

[0046] a: No heat treatment

[0047] b: heat treatment only

[0048] c: After heat treatment, immersion in 18% by mass hydrochloric acid for 2.5 minutes

[0049] d: After heat treatment, immersed in 18% by mass hydrochloric acid for 5 minutes

[0050] e: After heat treatment, immersion in 18% by mass hydrochl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com