Antibacterial active dressing and preparation method thereof

A technology of antibacterial activity and microspheres, which is applied in the field of antibacterial active dressings and its preparation, can solve the problems of cell irritation and poor water solubility, etc., and achieve improved performance of easy degradation, reduced dosage, good mechanical properties and biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

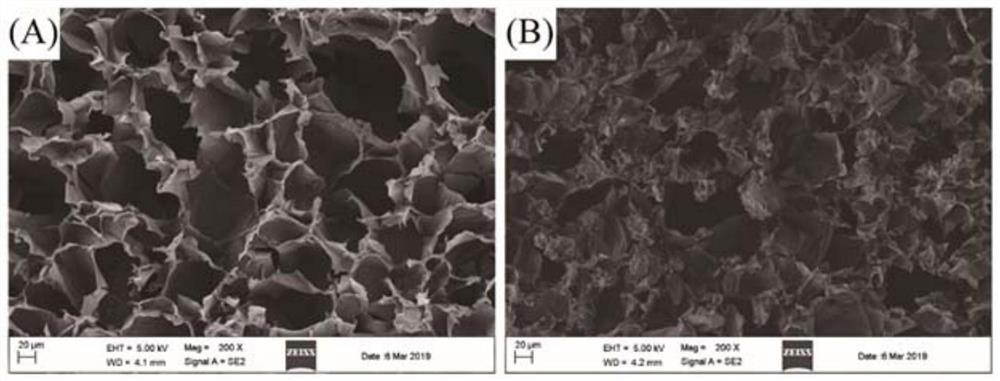

[0037]A kind of carboxymethylcellulose / sericin dressing (CMC / Ser), its preparation method is: sodium carboxymethylcellulose powder (2g) and sericin (0.2g) are added into 100mL deionized water gradually, then Stir gently until completely dissolved, add 0.1 g 5 wt.% citric acid (polymer weight) as a crosslinking agent and 0.06 g 3 wt.% glycerol (polymer weight) as a crosslinking extender, and then pour the mixture into poly Then, the mold was stored at -70°C overnight and freeze-dried; then, the sample was cross-linked at 70°C for 72 hours to obtain a carboxymethylcellulose / sericin dressing (CMC / Ser).

[0038] Among them, the preparation method of sericin protein is as follows: heat and alkali degumming method is used to extract sericin from silkworm cocoons, 5.0g silkworm cocoons are cut into pieces and washed with deionized water, immersed in 200mL 0.02M Na 2 CO 3 The solution was boiled for 1 hour, then the insoluble residue was removed by centrifugation (3500rpm, 10 minutes...

Embodiment 2

[0040] A kind of carboxymethylcellulose / sericin dressing (CMC / Ser), its preparation method is: add carboxymethylcellulose sodium powder (2g) and sericin (1g) gradually to 100mL deionized water, then gently Gently stir until completely dissolved, add 0.1g 5wt.% citric acid (polymer weight) as a crosslinking agent and 0.06g 3wt.% glycerin (polymer weight) as a crosslinking extender, and then pour the mixture into polytetrafluoroethylene Then, the mold was stored at -70°C overnight and freeze-dried; then, the sample was cross-linked at 70°C for 72 hours to obtain a carboxymethylcellulose / sericin dressing (CMC / Ser).

[0041] The preparation method of sericin is the same as that in Example 1.

Embodiment 3

[0043] A kind of carboxymethylcellulose / sericin dressing (CMC / Ser), its preparation method is: add carboxymethylcellulose sodium powder (2g) and sericin (2g) into 100mL deionized water gradually, then gently Gently stir until completely dissolved, add 0.1g 5wt.% citric acid (polymer weight) as a crosslinking agent and 0.06g 3wt.% glycerin (polymer weight) as a crosslinking extender, and then pour the mixture into polytetrafluoroethylene Then, the mold was stored at -70°C overnight and freeze-dried; then, the sample was cross-linked at 70°C for 72 hours to obtain a carboxymethylcellulose / sericin dressing (CMC / Ser).

[0044] The preparation method of sericin is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com