A kind of preparation method of cuprous oxide electrode

A cuprous oxide and electrode technology, applied in the field of electrochemistry, can solve the problems of high cost, poor structure uniformity, complex preparation process, etc., and achieve the effect of high capacitance value and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) The copper sheet was ultrasonically cleaned with a mixed solution of ethanol and deionized water, and then immersed in a sulfuric acid solution with a mass concentration of 10% for 5 hours to remove possible oxides on the surface of the copper sheet.

[0029] (2) Add 3.2g copper sulfate (0.02 mol), 1.0g ferric sulfate, 0.2g phenyltrimethylammonium chloride, 0.2g benzylamine in 100g deionized water, stir and dissolve, and use 10% Sulfuric acid adjusted the pH of the solution to 5.1.

[0030] (3) take the processed copper sheet as the negative electrode and the platinum sheet as the anode, and the prepared solution of the step (2) is the electrodeposition solution, at room temperature, the current density is 70mA / cm 2 Under the condition of DC electrodeposition for 5 minutes; after the reaction, the sample was washed with deionized water and dried at 150°C for 2 hours to obtain a cuprous oxide electrode.

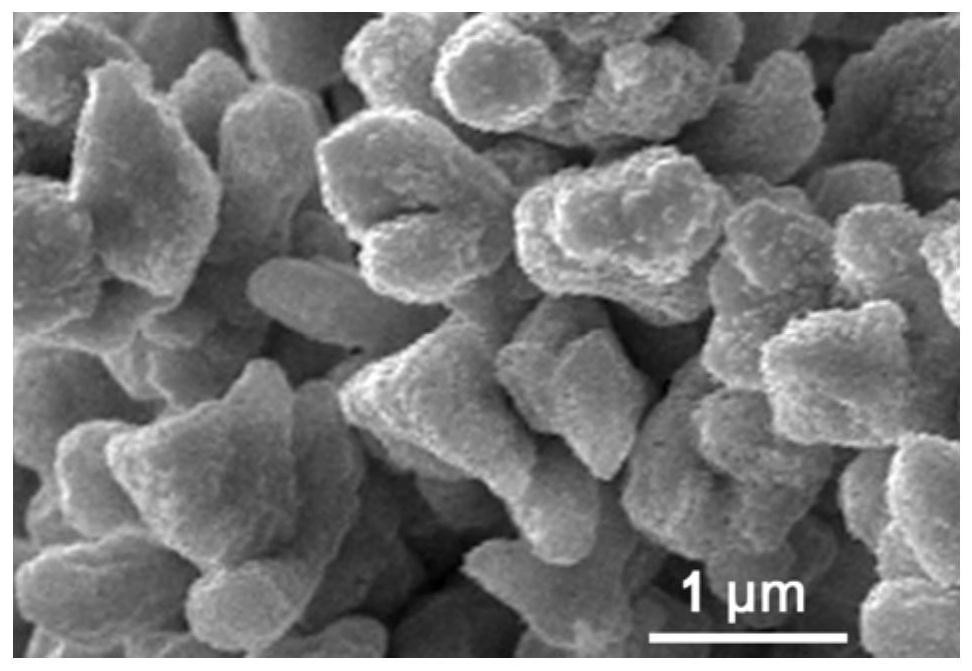

[0031] The morphology and structure of the prepared cuprous o...

Embodiment 2

[0034] (1) Change sulfuric acid into hydrochloric acid, carry out pretreatment to copper sheet with embodiment 1 (1) process step.

[0035] (2) Add 2.7g cupric chloride, 0.5g ferric chloride, 0.3g phenyltrimethylammonium chloride, 0.1g phenethylamine in 100g deionized water, stir and dissolve, and adjust with 10% sulfuric acid with mass concentration The pH of the solution was 5.6.

[0036] (3) At 120mA / cm 2 Under the condition of direct current electrodeposition for 3 minutes, the other process steps are the same as in Example 1 (3), and a cuprous oxide electrode can be prepared.

Embodiment 3

[0038] (1) Copper sheet is carried out pretreatment with embodiment 1 (1) technological step.

[0039] (2) add 3.6g copper acetate, 1.5g ferric sulfate, 0.1g benzyltrimethylammonium chloride, 0.3g cyclohexylamine in 100g deionized water, stir and dissolve, be the sulfuric acid adjustment solution of 10% with mass concentration The pH is 4.3.

[0040] (3) At 40mA / cm 2 Under the conditions of direct current electrodeposition for 8 minutes, other process steps are the same as in Example 1 (3), and a cuprous oxide electrode can be prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com