Electricity-membrane coupled water treatment system with clean energy and water treatment method

A treatment system and coupled water technology, applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of limiting the practical application of electrochemical oxidation degradation technology, low degradation efficiency, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

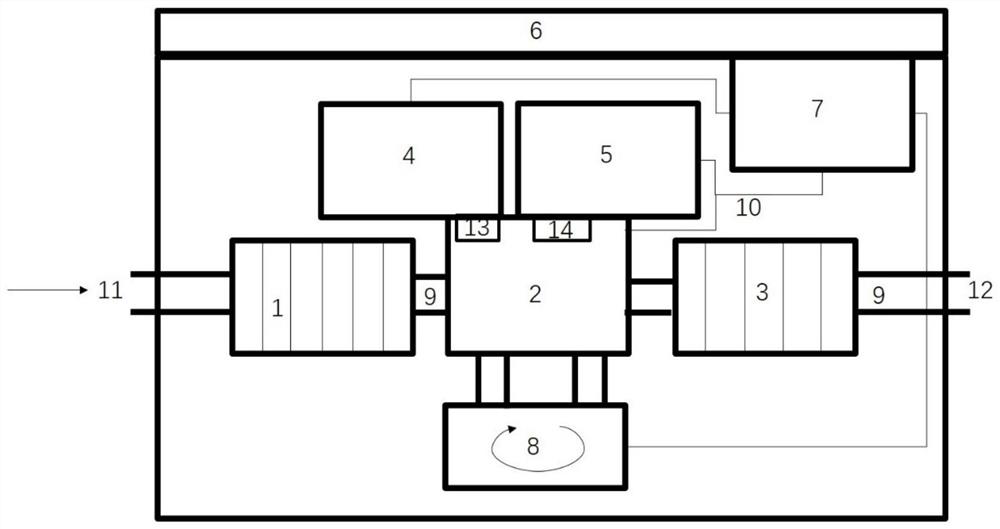

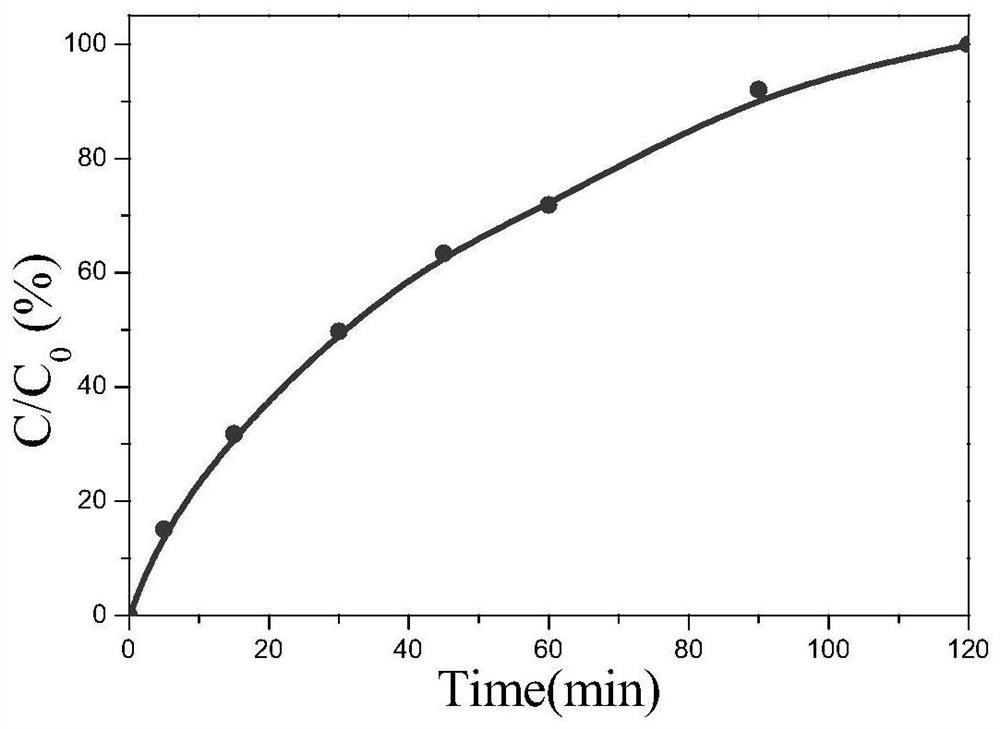

[0086] The above system is used to treat and degrade antibiotic-tetracycline hydrochloride (TCH) simulated wastewater. The TCH in the simulated organic wastewater is 1g / L. The filter module performs the second filtration, and the water filtered through the second time enters the electrochemical degradation module. After entering the electrochemical degradation module, the circulation pump is turned on. During the electrochemical treatment process, the electrolyte concentration is sodium sulfate (0.01M), and the applied current is 0.6A, the ultrasound is provided by the ultrasonic generation template, the power of the ultrasound provided is 100W, the ozone is fed into the gas control module, the output of ozone is 150g / min, and the concentration of ozone is 25mg / L; The water is then separated by nanofiltration through the nanofiltration separation module, and the intercepted concentrated water is returned to the electrochemical degradation module for electrochemical oxidation tr...

Embodiment 2

[0089] The above-mentioned system is used to degrade the high-salt wastewater of a chemical plant in Shandong. The high-salt wastewater first enters the coarse filtration module for the first filtration, and then enters the fine filtration module for the second filtration, and the second-filtered water enters the electrochemical degradation module. , after entering the electrochemical degradation module, turn on the circulating water pump. During the electrochemical treatment, the electrolyte concentration is sodium sulfate (0.01M), the applied current is 0.6A, and the ultrasound is provided by the ultrasonic generator template. The power of the ultrasound is 100W. The gas control module is fed with ozone, the ozone output is 150g / min, and the ozone concentration is 25mg / L; the electrochemically treated water is obtained through electrochemical oxidation treatment, and then the nanofiltration separation module is used for nanofiltration separation. The water returns to the elec...

Embodiment 3

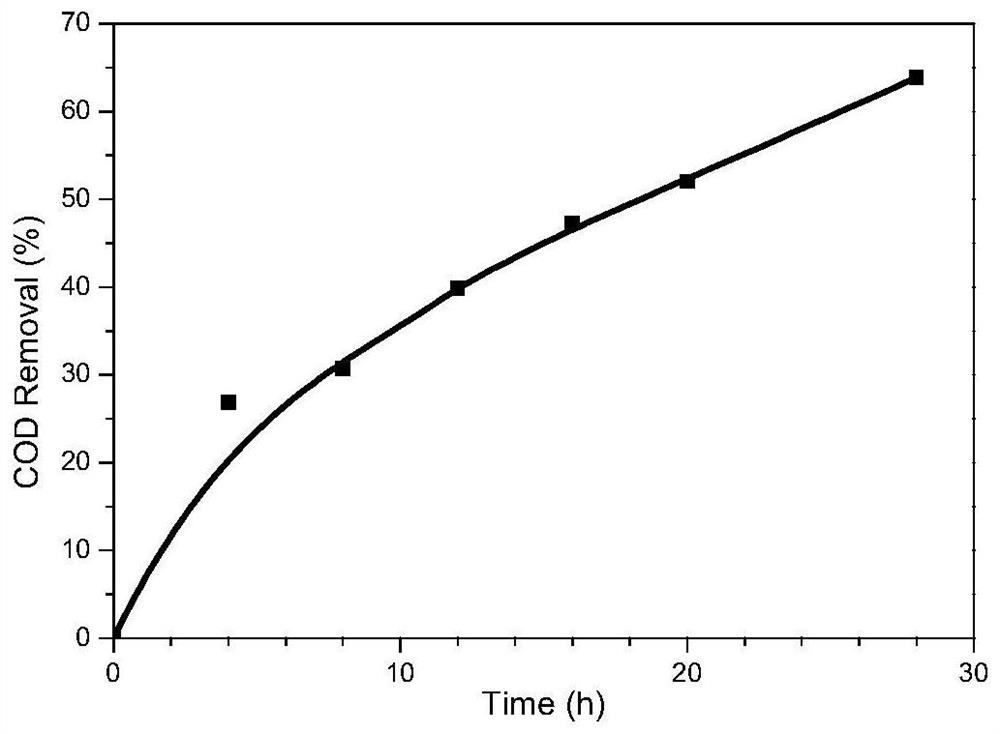

[0092] The above system is used to treat and degrade the landfill leachate. The landfill leachate first enters the coarse filtration module for the first filtration, and then enters the fine filtration module for the second filtration. After the second filtration, the water enters the electrochemical degradation module and enters the electrochemical After degrading the module, turn on the circulating water pump. During the electrochemical treatment, the electrolyte concentration is sodium sulfate (0.01M), the applied current is 0.6A, and the ultrasound is provided by the ultrasonic generation template. The power of the ultrasound is 100W, and the gas control module passes Into ozone, the ozone output is 150g / min, and the ozone concentration is 25mg / L; electrochemical oxidation treatment obtains electrochemically treated water, and then nanofiltration separation is carried out through the nanofiltration separation module, and the intercepted concentrated water is returned to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com