Low-temperature curing powder coating and preparation method thereof

A powder coating and low-temperature technology, which is applied in the field of low-temperature curing powder coating and its preparation, can solve the problems of difficult to meet high requirements, short curing time, reduce curing temperature and curing time, and reduce the occurrence of pinholes in the coating film , Improve the anti-interference ability and improve the hardness of the coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

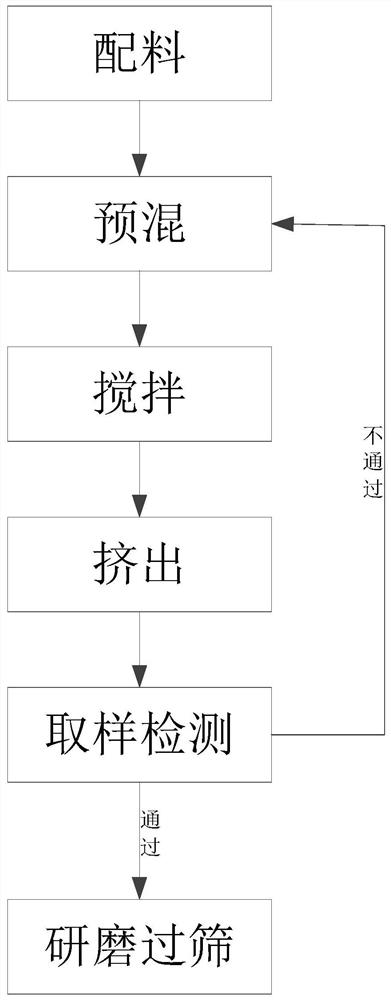

[0043] The production detection process of the present embodiment is as follows:

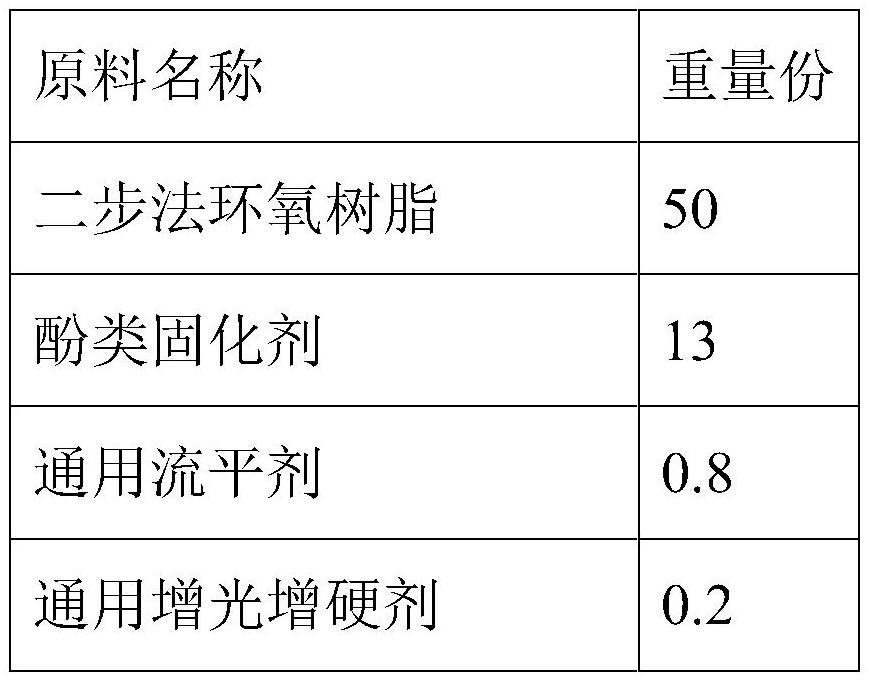

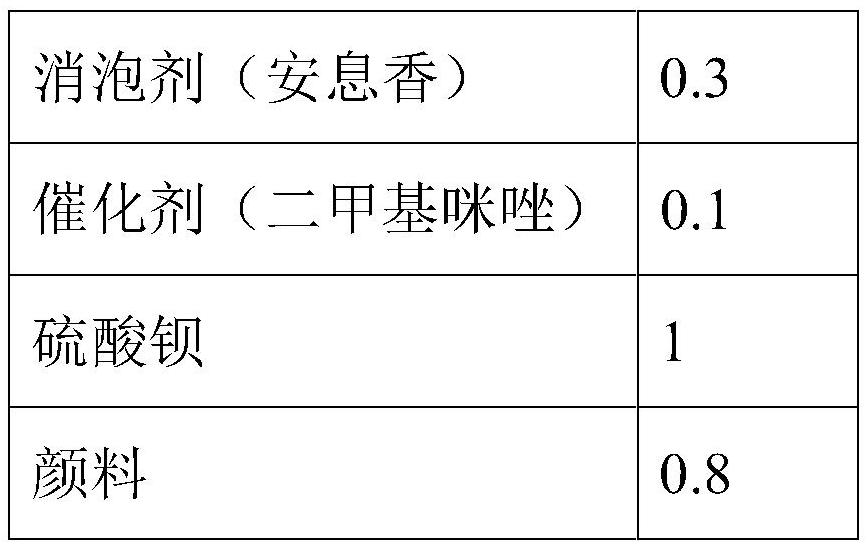

[0044] 1. Ingredients: Weigh the corresponding production raw materials according to the following raw material formula table.

[0045]

[0046]

[0047] 2. Premix:

[0048] Put the weighed raw materials into 1 / 2 two-step epoxy resin into the mixing tank first, then put all other raw materials into the mixing tank, and finally put the remaining 1 / 2 two-step epoxy resin into the mixing tank;

[0049] 3. Stirring:

[0050] After the feeding is completed, first set the stirring tank to stir at a slow speed for 3 minutes, and then set the stirring tank to stir quickly for 60 seconds; wherein, the speed frequency of the slow stirring of the stirring tank is 20 Hz, and the speed frequency of the fast stirring is 40 Hz.

[0051] 4. Extrusion:

[0052] The uniformly stirred mixed raw materials are put into the feeding hopper of the extruder, which has the function of cooling and crushing, and i...

Embodiment 2

[0063] The production detection process of the present embodiment is as follows:

[0064] 1. Ingredients: Weigh the corresponding production raw materials according to the following raw material formula table.

[0065]

[0066]

[0067] 2. Premix:

[0068] Put the weighed raw materials into 1 / 2 two-step epoxy resin into the mixing tank first, then put all other raw materials into the mixing tank, and finally put the remaining 1 / 2 two-step epoxy resin into the mixing tank;

[0069] 3. Stirring:

[0070] After the feeding is completed, first set the stirring tank to stir at a slow speed for 3 minutes, and then set the stirring tank to stir quickly for 60 seconds; wherein, the speed frequency of the slow stirring of the stirring tank is 20 Hz, and the speed frequency of the fast stirring is 40 Hz.

[0071] 4. Extrusion:

[0072] The uniformly stirred mixed raw materials are put into the feeding hopper of the extruder, which has the function of cooling and crushing, and i...

Embodiment 3

[0083] The production detection process of the present embodiment is as follows:

[0084] 1. Ingredients: Weigh the corresponding production raw materials according to the following raw material formula table.

[0085] raw material name parts by weight Two-step epoxy resin 55 Phenolic curing agent 15 Universal leveling agent 1.0 Universal brightening and hardening agent 0.3 Defoamer (benzoin) 0.4 Catalyst (Dimethylimidazole) 0.5 Barium sulfate 18 pigment 12

[0086] 2. Premix:

[0087] Put the weighed raw materials into 1 / 2 two-step epoxy resin into the mixing tank first, then put all other raw materials into the mixing tank, and finally put the remaining 1 / 2 two-step epoxy resin into the mixing tank;

[0088] 3. Stirring:

[0089] After the feeding is completed, first set the stirring tank to stir at a slow speed for 3 minutes, and then set the stirring tank to stir quickly for 60 seconds; wherein, the speed fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com