Preparation method of high-strength thermal insulation mortar

一种保温砂浆、高强度的技术,应用在陶瓷制品、应用、家里用具等方向,能够解决导热系数、干表观密度和收缩率大、搅拌工艺不合理搅拌时间搅拌强度、不能满足保温砂浆特殊要求等问题,达到缩短固化干燥的时间、降低干表观密度、导热系数降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

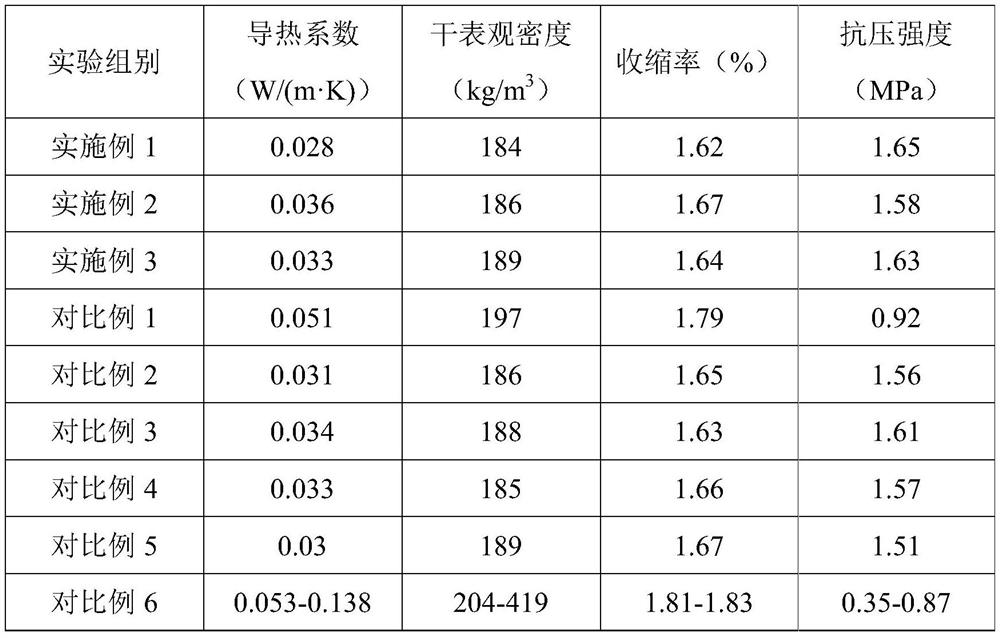

Examples

Embodiment 1

[0025] A thermal insulation mortar, in parts by weight, comprising the following raw materials: 112 parts of Portland cement, 8 parts of fly ash, 10 parts of limestone powder, 14 parts of polystyrene particles, 10 parts of bentonite, 4 parts of thickener, 6 parts of double fly powder, 5 parts of thickener, 3 parts of carboxyethyl methylcellulose, 1.2 parts of sodium lauryl sulfate, 13 parts of calcium fluoride, 15 parts of styrene-maleic anhydride copolymer, 26 parts of sodium carbonate , 6 parts of hydrochloric acid.

[0026] The thickener is cellulose ether;

[0027] Described tackifier is ethylene-vinyl acetate copolymer latex powder;

[0028] The molar concentration of described hydrochloric acid is 3mol / L;

[0029] The preparation method of described thermal insulation mortar, comprises the following steps:

[0030] S1: Mix Portland cement, fly ash, limestone powder, polystyrene granules, bentonite, thickener, double fly powder, thickener, carboxyethyl methyl cellulose...

Embodiment 2

[0034] A kind of thermal insulation mortar, which comprises the following raw materials in parts by weight: 96 parts of Portland cement, 5 parts of fly ash, 12 parts of limestone powder, 15 parts of polystyrene particles, 9 parts of bentonite, 5 parts of thickener, 4 parts of double fly powder, 6 parts of thickening agent, 2 parts of carboxyethyl methyl cellulose, 0.8 parts of sodium lauryl sulfate, 14 parts of calcium fluoride, 16 parts of silicone-polyurethane copolymer, 22 parts of sodium carbonate, 7 parts of hydrochloric acid.

[0035] The thickener is cellulose ether;

[0036] Described tackifier is ethylene-vinyl acetate copolymer latex powder;

[0037] The molar concentration of described hydrochloric acid is 2mol / L;

[0038] The preparation method of described thermal insulation mortar, comprises the following steps:

[0039] S1: Mix Portland cement, fly ash, limestone powder, polystyrene granules, bentonite, thickener, double fly powder, thickener, carboxyethyl meth...

Embodiment 3

[0043] A thermal insulation mortar, in parts by weight, comprising the following raw materials: 120 parts of Portland cement, 10 parts of fly ash, 6 parts of limestone powder, 10 parts of polystyrene particles, 12 parts of bentonite, 3 parts of thickener, 7 parts of double fly powder, 4 parts of thickener, 4 parts of carboxyethyl methylcellulose, 1.5 parts of sodium lauryl sulfate, 12 parts of calcium fluoride, styrene maleic anhydride copolymer or silicone-polyurethane copolymer 10 parts, 28 parts of sodium carbonate, 8 parts of hydrochloric acid.

[0044] The thickener is cellulose ether;

[0045] Described tackifier is ethylene-vinyl acetate copolymer latex powder;

[0046] The molar concentration of described hydrochloric acid is 4mol / L;

[0047] The preparation method of described thermal insulation mortar, comprises the following steps:

[0048] S1: Mix Portland cement, fly ash, limestone powder, polystyrene granules, bentonite, thickener, double fly powder, thickener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com