Catalyst, preparation method thereof and method for synthesizing hexamethylenediamine intermediate

A catalyst and carrier technology, applied in the field of synthesizing hexamethylenediamine intermediates, catalysts and their preparation, can solve the problem of many by-products, and achieve the effects of reducing by-products, improving selectivity, and reducing mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

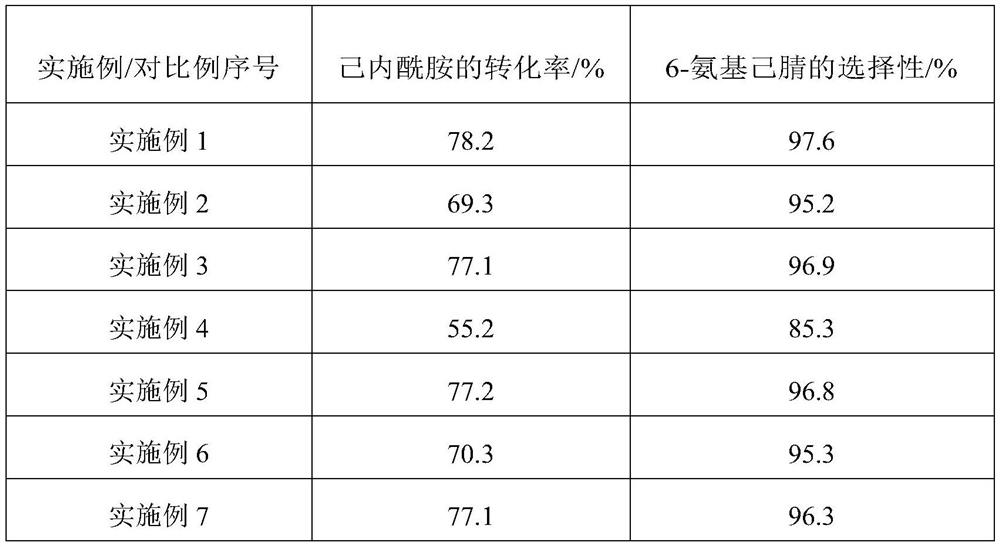

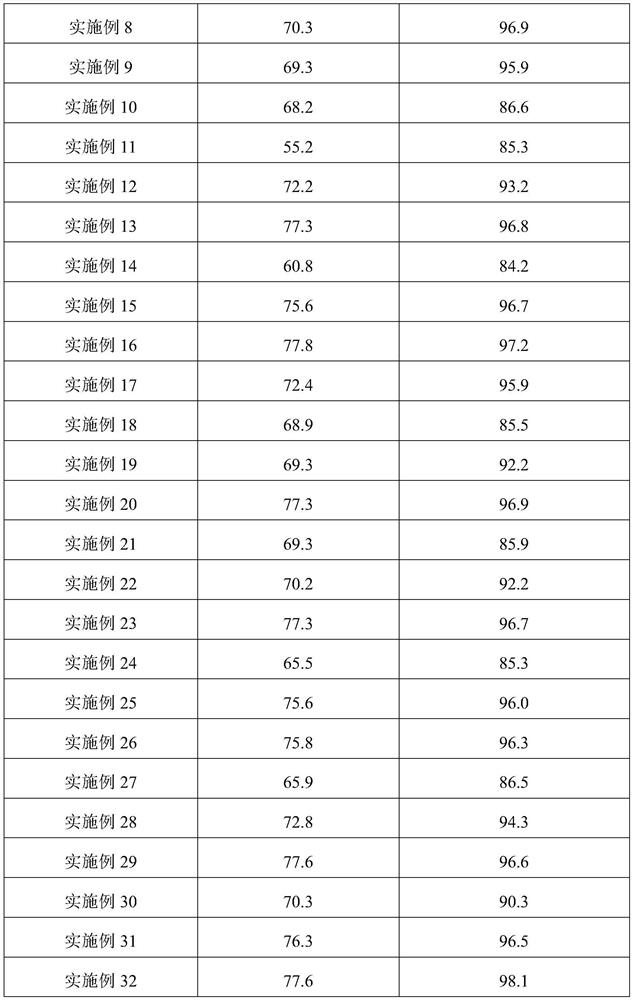

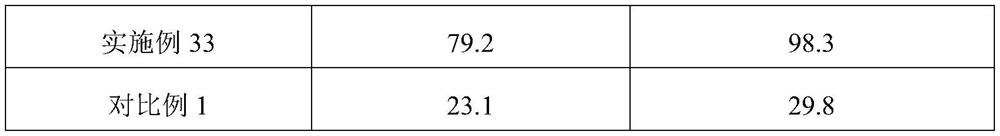

Examples

preparation example Construction

[0028] In another typical embodiment of the present application, a preparation method of the aforementioned catalyst is provided, the preparation method comprising: step S1, mixing the shell-forming solution and the carrier to obtain a mixture; step S2, adjusting the pH value of the mixture To coat the carrier to obtain the coated system; and step S3, subjecting the coated system to solid-liquid separation, drying for the first time, and roasting for the first time to obtain a catalyst, wherein the shell-forming solution is selected from aluminum nitrate solution , any one or more of zinc nitrate solution, copper nitrate solution, ferric nitrate solution, aluminum sulfate solution.

[0029] Fully mix the above-mentioned shell-forming solution with the carrier, and adjust the pH so that the shell-forming solution forms a precipitate and coats the carrier to obtain the coated system, and then separate the obtained solid components by solid-liquid separation of the coated system ...

Embodiment 1

[0047] Weigh 10g of aluminum nitrate and dissolve it in 100g of water, slowly add 30g of calcium oxide to the aluminum nitrate solution at 90°C, and stir for 4h to obtain a mixture, after stirring the mixture for 30min, slowly add 10% ammonia solution dropwise until the pH value is 8 Between ~10, continue to stir for 1 hour, so that the aluminum ions are completely precipitated and coated on the calcium oxide carrier, and the coated system is obtained. After the coated system is filtered and washed twice, the filter residue is dried in an oven at 60°C After drying for 20 hours, the catalyst was further roasted in a muffle furnace at 650°C for 5 hours to obtain the desired catalyst Al with a core-shell structure. 2 o 3 -CaO, the shell thickness of the catalyst is 10nm, Al 2 o 3 The molar ratio with CaO is 0.045:1, Al 2 o 3 The pore diameter of the shell layer is 30-40 μm.

[0048] Take 20g of the above-mentioned catalyst and put it into a kneader, add 2g of turnip powder a...

Embodiment 2

[0050] The difference between embodiment 2 and embodiment 1 is that

[0051] Weigh 1.14g of aluminum nitrate and dissolve it in 100g of water, add 30g of calcium oxide to obtain the required catalyst Al with a core-shell structure 2 o 3 -CaO, the Al 2 o 3 -CaO catalyst with shell thickness of 0.1nm, Al 2 o 3 The molar ratio with CaO is 0.005:1, Al 2 o 3 The pore diameter of the shell layer is 10-30 μm, and a cylindrical catalyst with a diameter of 4 mm is finally obtained after molding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Shell thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com