Sulfur-resistant and water-resistant manganese low-temperature denitration catalyst and preparation method thereof

A low-temperature denitration and catalyst technology, which is used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. It can reduce the production cost, enhance the ability of sulfur and water resistance, and enhance the sulfur resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

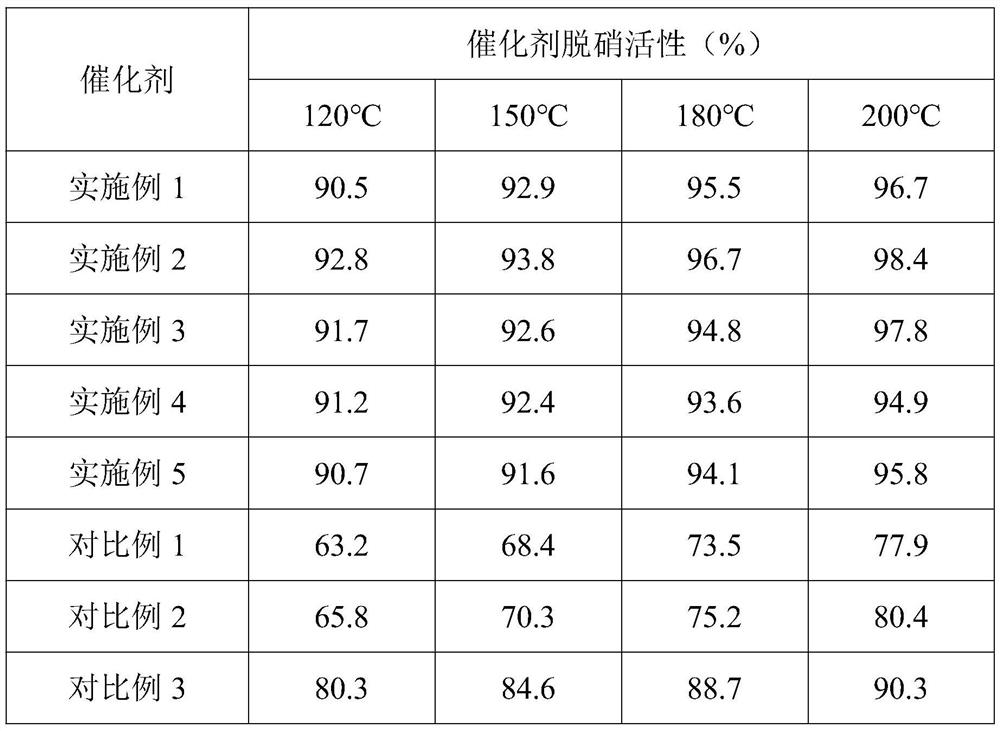

Examples

Embodiment 1

[0028] Example 1 A manganese-based low-temperature denitration catalyst with high sulfur and water resistance and low cost, and the preparation method is as follows:

[0029] (1) According to m TiO2 / V NaOH (g / ml)=0.005 added to 8mol / L sodium hydroxide solution and stirred for 30min, then placed in a hydrothermal reaction kettle at 150℃ for airtight reaction for 24h, after cooling, washed with 0.05mol / L HCl, and washed with deionized water until neutral . After drying at 60°C for 10 hours, a titanium dioxide nanotube precursor was obtained.

[0030] (2) Add 5 parts of molybdenum disulfide, 3 parts of 30% wt silica sol, 1 part of propylhydroxymethyl cellulose, 3 parts of glass fiber, and 2 parts of aluminum dihydrogen phosphate to 85 parts of titanium dioxide nanotube precursor. It is mixed with 120 parts of deionized water, stale, honeycomb extrusion molding, dried at 60°C for 48h, and calcined at 300°C for 24h to obtain a titanium dioxide nanotube honeycomb carrier.

[0031] (3) ...

Embodiment 2

[0032] Example 2 A manganese-based low-temperature denitration catalyst with high sulfur and water resistance and low cost, the preparation method is as follows:

[0033] (1) According to m TiO2 / V KOH (g / ml)=0.01 added to 12mol / L potassium hydroxide solution and stirred for 60min, then placed in a hydrothermal reaction kettle at 220℃ for 12h airtight reaction, after cooling, use 0.1mol / LH 2 SO 4 Wash, wash with deionized water to neutral. After drying at 100°C for 8 hours, a titanium dioxide nanotube precursor was obtained.

[0034] (2) Add 10 parts of tungsten disulfide, 5 parts of 30% wt silica sol, 3 parts of propylhydroxymethyl cellulose, 5 parts of glass fiber, and 8 parts of aluminum dihydrogen phosphate to 75 parts of titanium dioxide nanotube precursor. It is mixed with 150 parts of deionized water, stale, honeycomb extrusion molding, dried at 80°C for 24 hours, and calcined at 500°C for 12 hours to obtain a titanium dioxide nanotube honeycomb carrier.

[0035] (3) Prepar...

Embodiment 3

[0036] Example 3 A manganese-based low-temperature denitrification catalyst with high sulfur and water resistance and low cost, the preparation method is as follows:

[0037] (1) According to m TiO2 / V NaOH (g / ml)=0.008 was added to 10mol / L sodium hydroxide solution and stirred for 60min, then placed in a hydrothermal reaction kettle at 210℃ for airtight reaction for 24h, after cooling, use 0.05mol / LHNO 3 Wash, wash with deionized water to neutral. After drying at 90°C for 10 hours, a titanium dioxide nanotube precursor was obtained.

[0038] (2) Add 3 parts of molybdenum disulfide, 3 parts of tungsten disulfide, 4 parts of 30%wt silica sol, 3 parts of propylhydroxymethyl cellulose, 5 parts of glass fiber to 80 parts of titanium dioxide nanotube precursor. Mixing 6 parts of aluminum dihydrogen phosphate and 135 parts of deionized water, aging, honeycomb extrusion molding, drying at 70°C for 36 hours, and calcining at 400°C for 18 hours to obtain a titanium dioxide nanotube honeyco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com