Diaphragm with reversible thermal shutdown performance, and preparation method and application thereof

A thermal shutdown and performance technology, applied in electrical components, electrochemical generators, circuits, etc., can solve the problems of few channels, unusable batteries, large lithium ion transmission impedance, etc., to improve safety performance and increase internal resistance , Extend the effect of application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

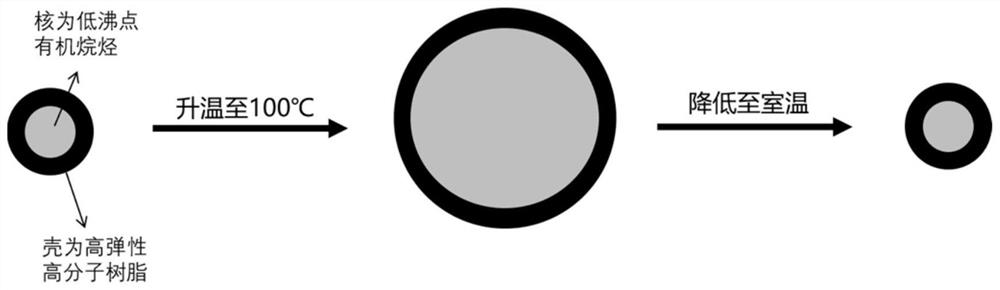

[0059] Example 1: Synthesis of polymer microspheres with core-shell structure

[0060] 600g of deionized water, 7.5g of sodium dodecylsulfonate, 7.5g of Tween 80, and 100g of cyclohexane were added to the high-pressure sealed reactor and replaced with nitrogen for 3 times. Then the temperature was raised to 70 ° C, and the stirring speed was 500 r min -1 ; Add 189g of 1,3-butadiene, 81g of styrene, 30g of ethylene glycol dimethacrylate monomers and 2.4g of ammonium persulfate as initiator to carry out polymerization reaction. After the reaction is kept for 6 hours, the temperature is lowered, the material is discharged, and spray-dried at a temperature not higher than 50° C. to obtain heat-responsive polymer microspheres whose outer shell is cross-linked styrene-butadiene rubber and whose core is cyclohexane.

[0061] The mass fraction of alkanes in the obtained polymer microspheres was 24.8%.

Embodiment 2-20

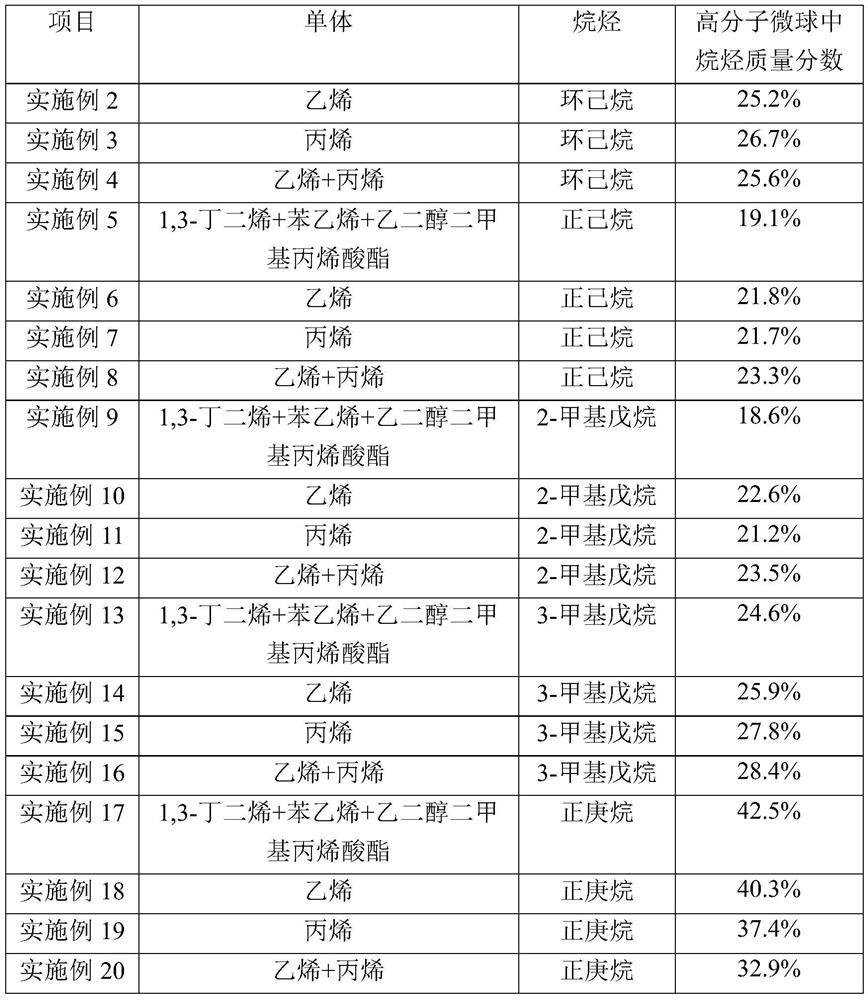

[0062] Example 2-20: Synthesis of polymer microspheres with core-shell structure

[0063] Example 2-20 Polymer microspheres with a core-shell structure were prepared in the same manner as in Example 1, except that the polymerized monomer and the inner core alkane were replaced, see Table 1.

[0064] Table 1 Different monomers and alkanes used to prepare polymer microspheres and the mass fraction of alkanes in the prepared polymer microspheres.

[0065]

Embodiment 21

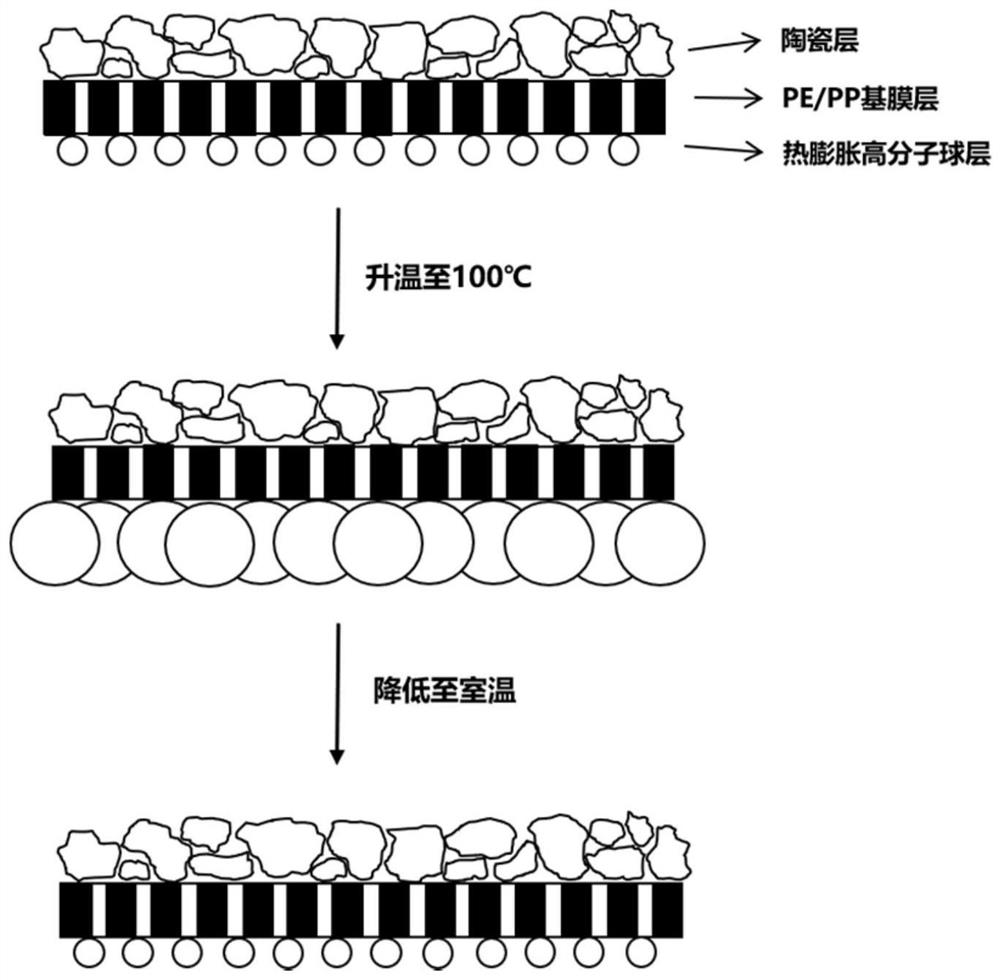

[0066] Example 21: Preparation of Composite Diaphragm

[0067] Alumina powder (D50: 350nm), sodium polyacrylate aqueous solution (Lubrizol K702), acrylonitrile copolymer binder (Indile LA133) were added to the mixer according to the mass ratio of 97:0.7:6.3, and then Deionized water was added for slurry mixing and stirring, and the solid content was adjusted to 15% to obtain coating ceramic slurry.

[0068] The polymer microspheres in Example 1, sodium polyacrylate aqueous solution (Lubrizol K702), and styrene-butadiene rubber binder (Zion 451B) were added to the agitator according to the mass ratio of 90:0.5:9.5, and then Deionized water was added for slurry mixing and stirring, and the solid content was adjusted to 15% to obtain the coated polymer microsphere slurry.

[0069] The obtained coated ceramic slurry was coated on one side of the polyethylene base film by gravure coating, and the coating thickness was 3 μm. After the ceramic coating was dried, a ceramic PE separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com