Infrared radiation insulating coating as well as paint and preparation method thereof

A coating and coating technology, applied in the field of infrared radiation insulating coating and its coating and preparation, can solve the problems of poor thermal conductivity, low radiation efficiency, and low radiation power of the insulating coating, achieve less thermal interface, enhance thermal radiation and Heat transfer efficiency, high degree of industrialization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The invention provides a method for preparing a multi-stage infrared radiation heating coating, which specifically includes the following steps:

[0026] (1) The graphene oxide solution with a concentration of 0.1 mg / mL was sprayed at 200°C, and reduced by HI at 80°C for 8 hours to prepare spherical graphene.

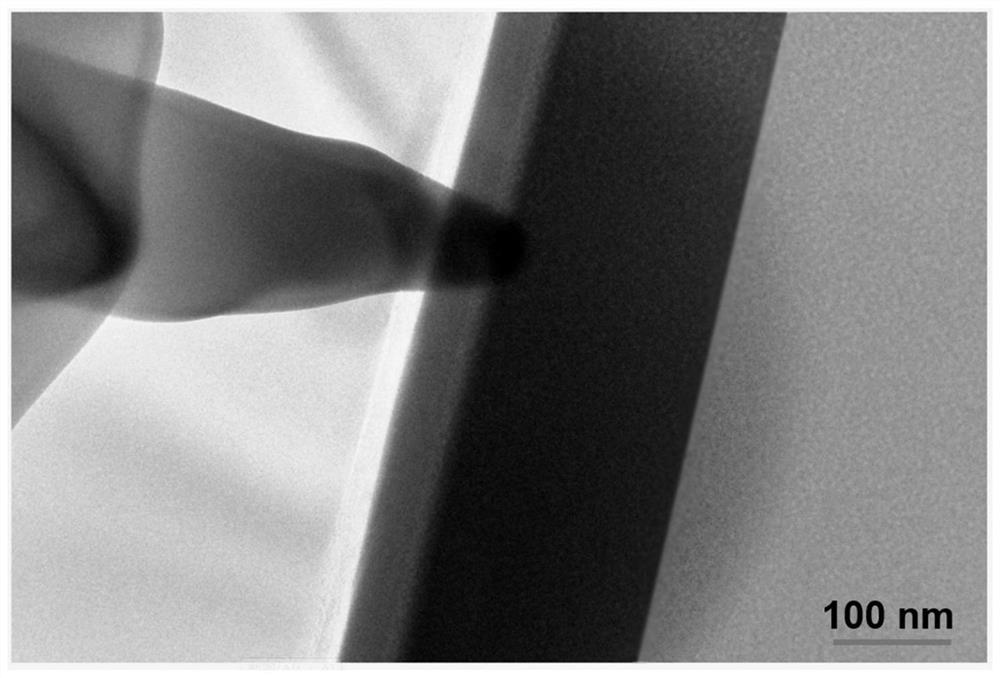

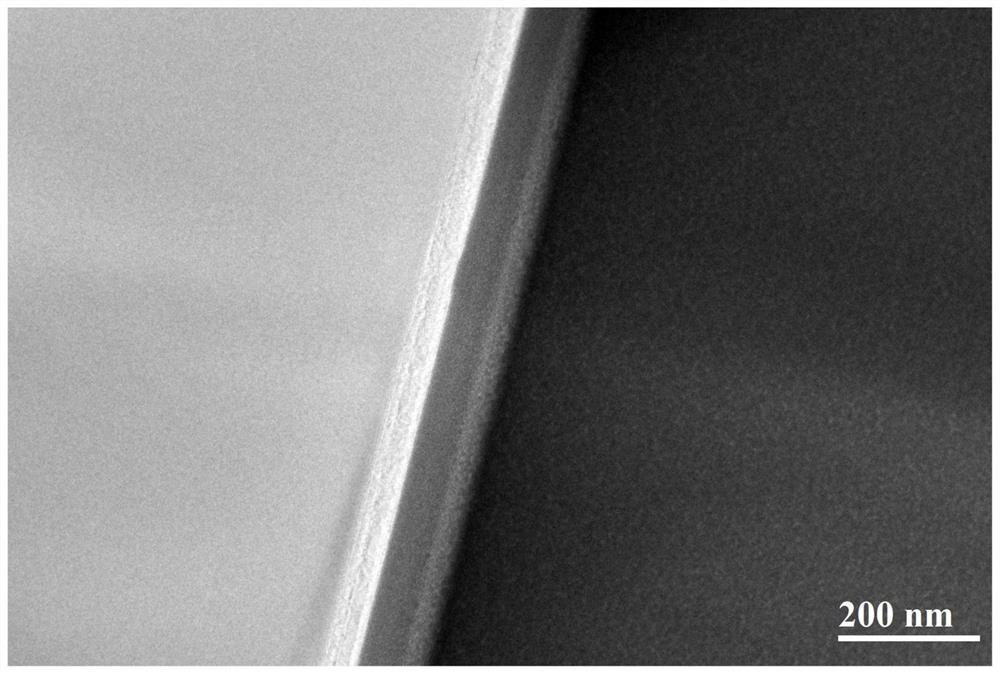

[0027] The scanning electron microscope test proves that the spherical graphene is finally obtained, and the I of the spherical graphene is detected by Raman detection. D / I G The value is 1.1, and its scale is 1 μm, and the wall thickness of spherical graphene is 2 atomic layers.

[0028] (2) Take the above-mentioned 1 weight part of spherical graphene and 0.02 weight part of polyimide with a molecular weight of 2000, 4 weight parts of feldspar nanopowder, 0.5 weight part of a molecular weight of 9800, a hyperbranched carbosilane with a degree of branching of 1.1, and 0.1 parts by weight of dicumyl peroxide were mixed uniformly to obtain a mixed coating.

[0...

Embodiment 2

[0034] A method for preparing a multi-stage infrared radiation heating coating, specifically comprising the following steps:

[0035] (1) The graphene oxide solution with a concentration of 1 mg / mL was sprayed at 180°C, and reduced by HI at 100°C for 2 hours to prepare spherical graphene.

[0036] It is proved by SEM detection that spherical highly wrinkled graphene is finally obtained, and by Raman detection, the I of the spherical graphene D / I G The value is 0.8, and its scale is 3 μm, and the wall thickness of spherical graphene is 4 atomic layers.

[0037] (2) Take the above-mentioned 1 weight part of spherical graphene and 0.12 weight part of pitch with a molecular weight of 10000, 1 weight part of mica nanopowder, 2 parts by weight of hyperbranched carbosilane with a molecular weight of 8000 and a degree of branching of 2 and 0.1 part by weight of hyperbranched carbosilane The oxidized benzoic acid is mixed uniformly to obtain a mixed paint.

[0038] (3) The mixed pa...

Embodiment 3

[0042] A method for preparing a multi-stage infrared radiation heating coating, specifically comprising the following steps:

[0043] (1) Graphene oxide with a concentration of 0.1 mg / mL was sprayed at 220°C, and reduced by HI at 90°C for 4 hours to prepare spherical graphene.

[0044] It is proved by SEM detection that multi-fold spherical graphene is finally obtained, and by Raman detection, the I of the spherical graphene D / I G The value is 0.8, and its scale is 2 μm, and the wall thickness of spherical graphene is 3 atomic layers.

[0045] (2) Take the above-mentioned 1 weight part of spherical graphene and 0.1 weight part of polyacrylonitrile with molecular weight of 10000, 2 weight parts of kaolin nanopowder, 1 weight part of hyperbranched carbosilane with molecular weight of 8000, branching degree of 1.6 and 0.05 weight part Parts of 2,5-dimethyl-2,5 bis(tert-butylperoxy)hexane were mixed uniformly to obtain a mixed paint.

[0046] (3) Spray the mixed paint obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com