Flexible environment-friendly high-temperature-resistant protective film and preparation method thereof

A high-temperature-resistant protective film and environmental protection technology, applied in the field of film manufacturing, can solve the problems of difficult to exert the performance of polymer film, the range of high-temperature resistance effect, and the inability to exert high strength, etc., to achieve enhanced molecular confinement effect and good heat insulation effect , Reduce the effect of heat conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

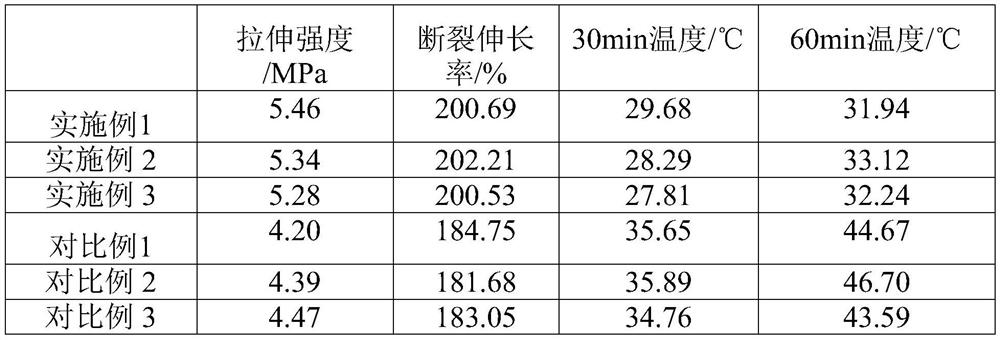

Examples

Embodiment 1

[0026] A kind of flexible environmental protection high temperature resistant protective film, this protective film comprises basic core layer, infrared reflective layer; The mass ratio of described basic core layer, infrared reflective layer is 8:0.1; In parts by mass, described infrared reflective layer consists of the following Raw materials: 5 parts of aromatic polyamide fibers, 0.3 parts of nano-copper oxide, 0.3 parts of nano-zinc sulfide, 0.05 parts of perfluoroalkyl polyether, 25 parts of phenolic resin modified neoprene, and 15 parts of polytetrafluoroethylene. The aromatic polyamide fiber is polyparaphenylene terephthalamide fiber; the fineness of the aromatic polyamide fiber is 0.8mm; the basic core layer is composed of the following raw materials in parts by mass: poly 10 parts of benzimidazole fiber, 0.5 part of basalt fiber, 0.2 part of nano-silica, 15 parts of epichlorohydrin rubber, 22 parts of o-cresol novolac epoxy resin, 8 parts of methyl silicone rubber, 30 ...

Embodiment 2

[0037]A kind of flexible environmental protection high temperature resistant protective film, this protective film comprises basic core layer, infrared reflective layer; The mass ratio of described basic core layer, infrared reflective layer is 5:0.1; In parts by mass, described infrared reflective layer consists of the following Raw materials: 3 parts of aromatic polyamide fiber, 0.1 part of nano-copper oxide, 0.1 part of nano-zinc sulfide, 0.01 part of perfluoroalkyl polyether, 15 parts of phenolic resin modified neoprene, and 5 parts of polytetrafluoroethylene The aromatic polyamide fiber polyphenylene isophthalamide fiber; the fineness of the aromatic polyamide fiber is 0.8mm; the basic core layer is composed of the following raw materials in parts by mass: polyphenylene 10 parts of imidazole fiber, 0.5 part of basalt fiber, 0.2 part of nano-silica, 15 parts of chlorohydrin rubber, 22 parts of o-cresol novolac epoxy resin, 8 parts of methyl silicone rubber, 30 parts of poly...

Embodiment 3

[0048] A kind of flexible environmental protection high temperature resistant protective film, this protective film comprises basic core layer, infrared reflective layer; The mass ratio of described basic core layer, infrared reflective layer is 7:0.1; In parts by mass, described infrared reflective layer consists of the following Raw materials: 4 parts of aromatic polyamide fibers, 0.23 parts of nano-copper oxide, 0.13 parts of nano-zinc sulfide, 0.03 parts of perfluoroalkyl polyether, 18 parts of phenolic resin modified neoprene, and 11 parts of polytetrafluoroethylene. The aromatic polyamide fiber is formed by mixing poly-p-phenylene terephthalamide fiber and poly-m-phenylene isophthalamide fiber at a mass ratio of 1:1; the aromatic polyamide The fiber fineness is 0.5 mm; the basic core layer is composed of the following raw materials in parts by mass: 9 parts of polybenzimidazole fiber, 0.4 part of basalt fiber, 1 part of nano-silica, 13 parts of chlorohydrin rubber, o-cres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com