Water-saving, energy-saving and low noise oil gas dual-purpose air blast range

A blast stove, low-noise technology, applied in the field of high-efficiency, energy-saving and low-noise blast stoves, can solve the problems of heat loss, burnout of sub-fire caps, electricity consumption, etc., to reduce heat loss, reduce heat energy absorption, and reduce heat conduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

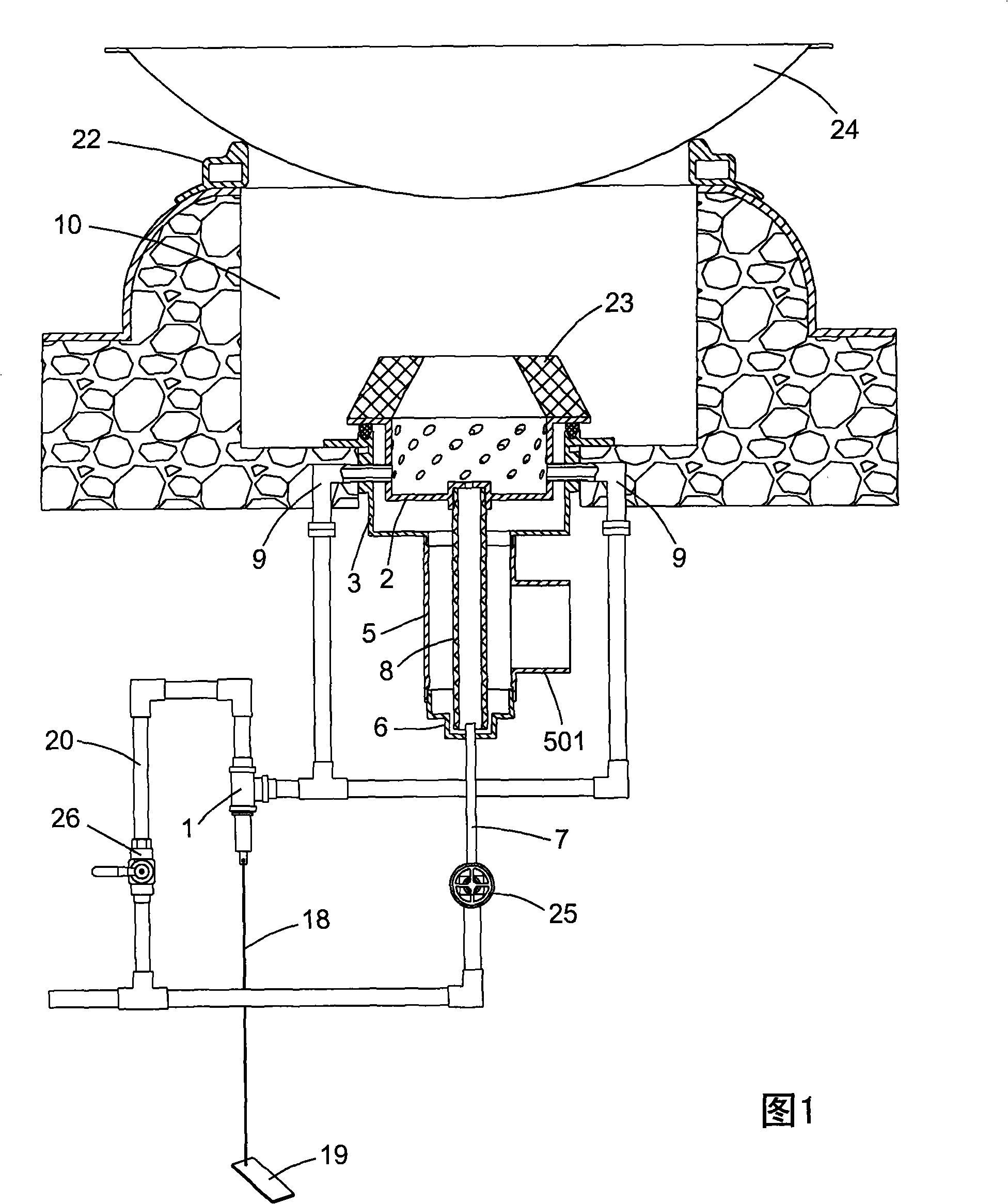

[0031] Label in the figure

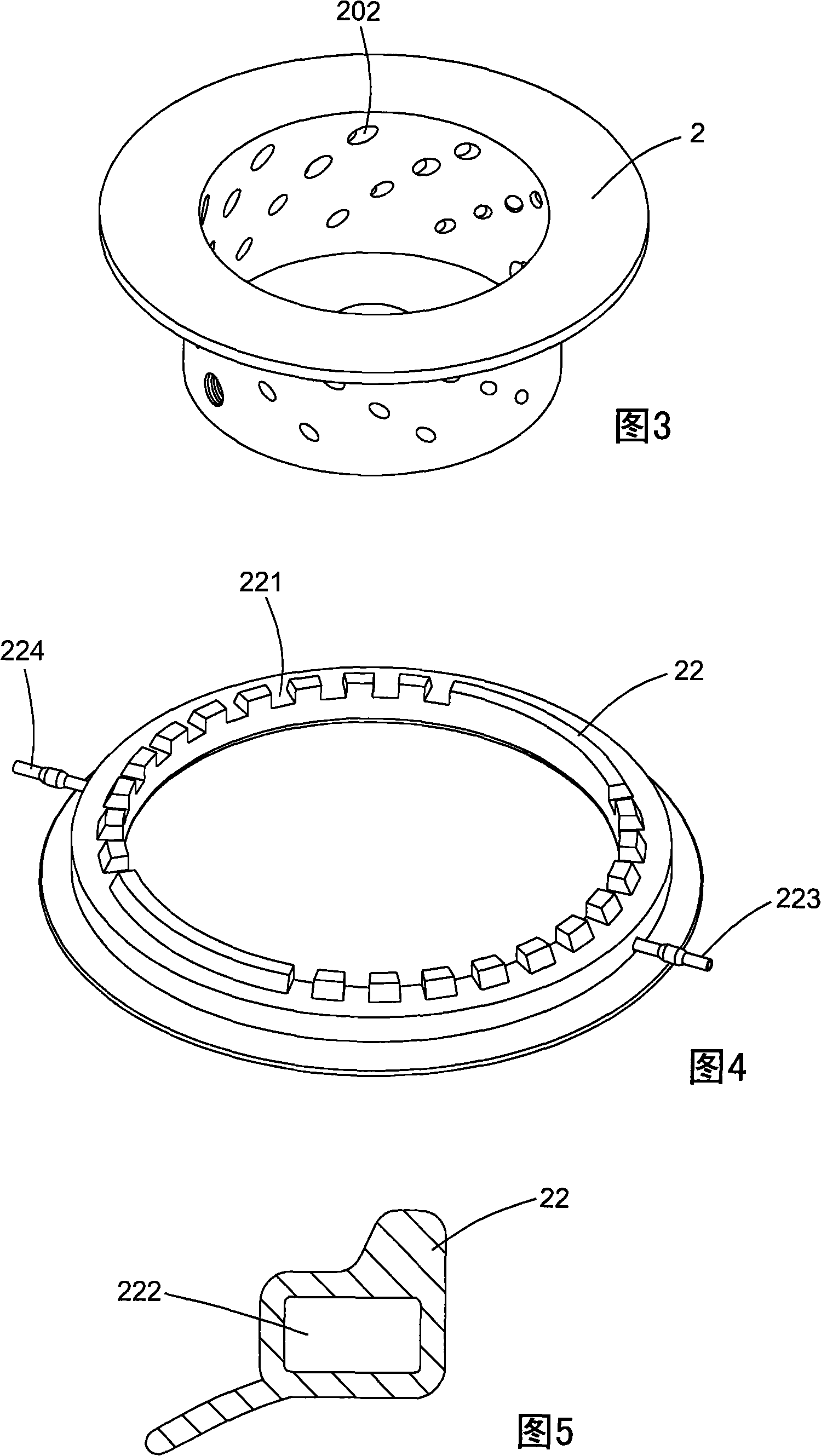

[0032] 1 foot valve 2 inner fire bowl

[0033] 201 Pipe head cap seat 202 Wind eye 203 Flange plate 204 Air outlet

[0034] 3 outer fire bowl 301 groove 303 flange

[0035] 4 air channel 5 air duct 501 nozzle

[0036] 6 plug 601 pipe head base 602 gap

[0037] 7 Auxiliary gas supply pipe 8 Casing pipe 9 Inlet pipe 10 Stove chamber

[0038] 11 valve body 111 inlet 112 outlet 113 valve port

[0039] 12 Stem 13 Disc 14 Stem Seat

[0040] 15 first spring 16 second spring 17 retaining ring 18 traction rope 19 pedal

[0041] 20 main gas supply pipe 21 insulation pad 22 stove ring 221 gap

[0042] 222 inner cavity 223 water inlet pipe 224 water outlet pipe

[0043] 23 fire ring 24 pot 25 needle valve 26 ball valve

[0044] 27 sealing ring 28 sealing ring 29 gasket

[0045] 30 nozzle 31 elbow 32 inner fire bowl 321 wind eye

[0046] 33 outer fire bowl 34 air cap 341 air eye

[0047] 35 intake pipe 36 screw 37 screw

[0048] Please refer to Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com