Composite material based on agricultural wastes as well as preparation method and application of composite material

A technology for agricultural waste and composite materials, which is applied in the field of agricultural waste-based composite materials and their preparation, can solve the problems that hinder the formation of stable entangled networks of macromolecules, the difficulty of cellulose to form entangled structures, the destruction of multi-level structures and the Crystal structure and other problems, to achieve the effect of improving the degree of dissolution that is difficult to control, good interface compatibility, and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

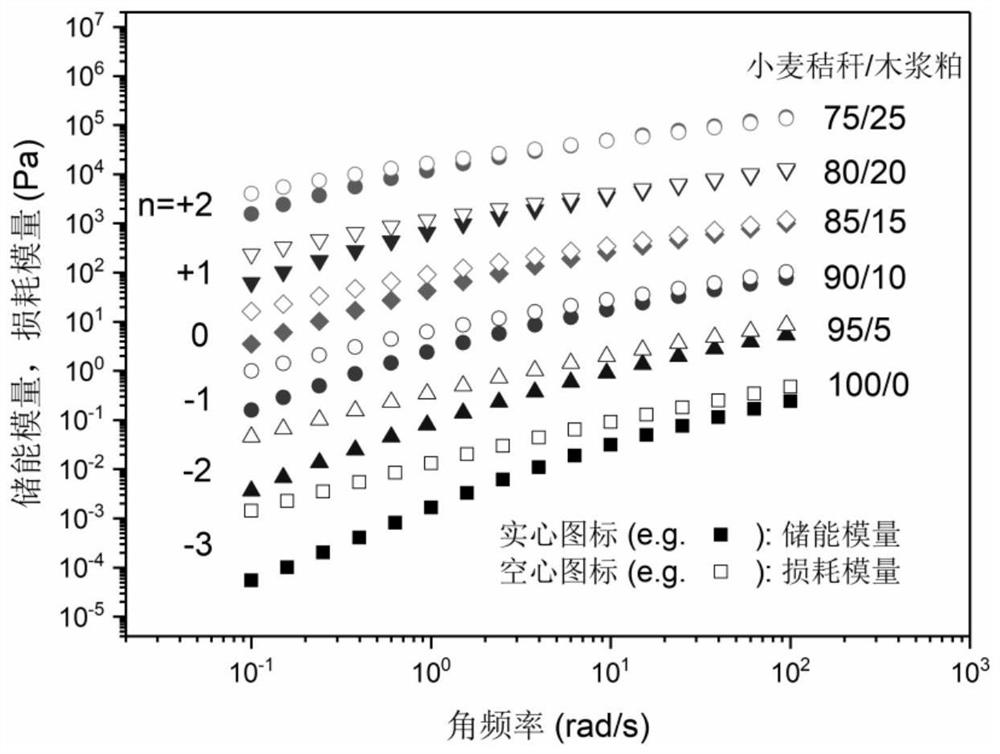

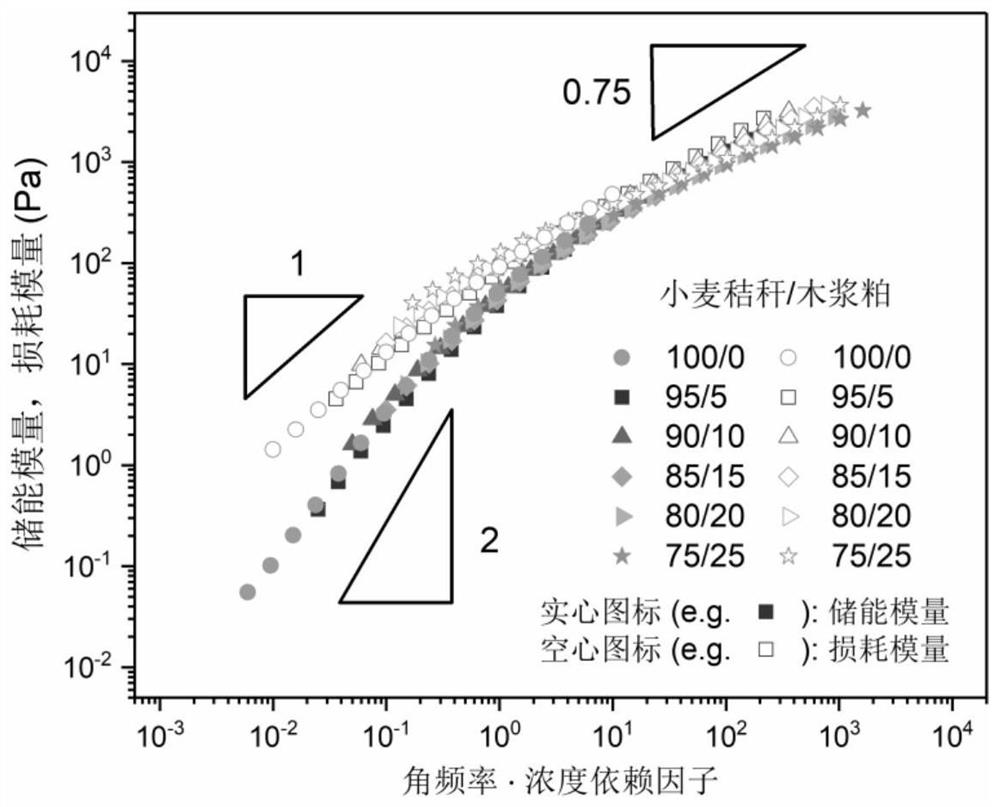

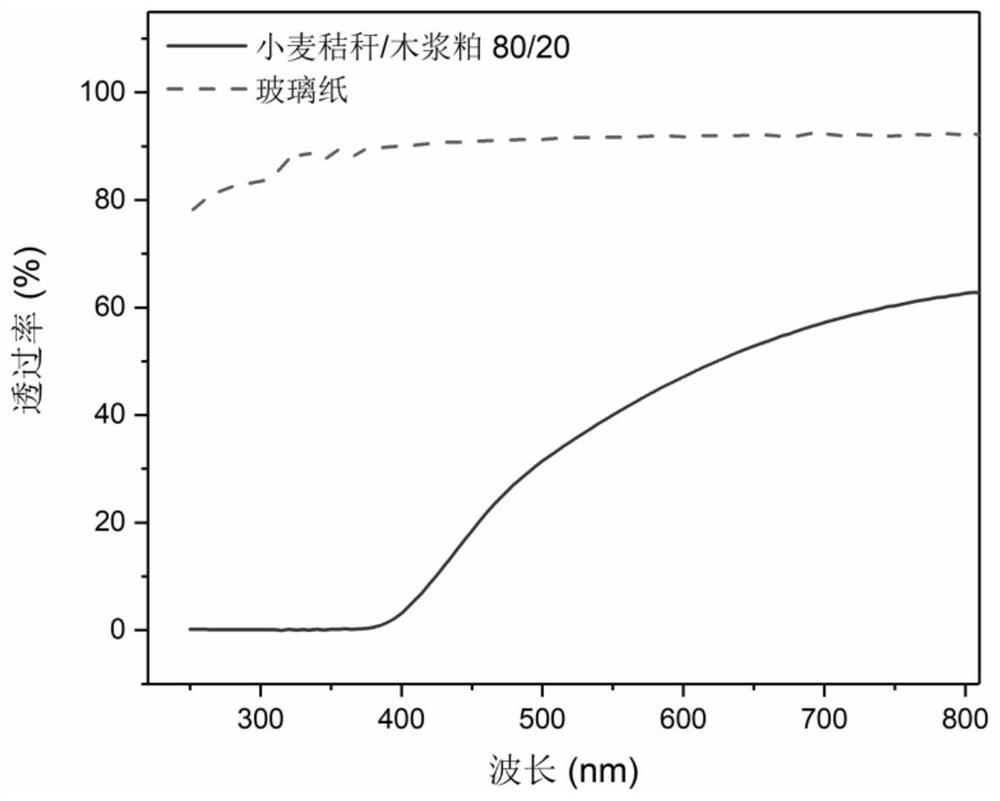

[0058] The selected agricultural waste raw material is wheat straw with a cellulose mass fraction of about 56%, and the selected cellulose raw material is wood pulp with a polymerization degree of about 1300. Weigh 19.2g of dry AMIMCl ionic liquid and 0.64g of dry wheat straw, stir and dissolve at 120°C, and form a uniform brown solution after about 120 minutes. Add 0.16g dry wood pulp to the solution, stir and dissolve further at 80°C, after about 60 minutes, a uniform brown wheat straw / wood pulp / AMIMCl mixed solution is obtained, observed with a polarizing microscope, the field of view is Black, indicating that the wheat straw cellulose and wood pulp are basically completely dissolved. The mass percentage of wheat straw in the wheat straw / wood pulp / AMIMCl mixed solution was 3.2%, and the mass ratio of wood pulp and wheat straw was 1:4. Spread the mixed solution of wheat straw / wood pulp / AMIMCl evenly on the surface of the glass plate, and put it into a coagulation pool with ...

Embodiment 2

[0062] The raw material of agricultural waste is rice straw, and its cellulose mass fraction is about 45%, and the selected cellulose raw material is wood pulp, and its degree of polymerization is about 1300. Weigh 9.2g of dry AMIMCl ionic liquid, weigh 0.64g of dry rice straw and 0.16g of dry wood pulp, stir and dissolve together at 120°C, and after about 180 minutes, uniform brown rice straw / wood pulp is obtained Meal / AMIMCl mixed solution was all black in the field of view observed with a polarizing microscope, indicating that the rice straw cellulose and wood pulp were basically completely dissolved. The mass percentage of rice straw in the rice straw / wood pulp / AMIMCl mixed solution was 6.4%, and the mass ratio of wood pulp and rice straw was 1:4. The mixed solution of rice straw / wood pulp / AMIMCl was evenly spread on the surface of the glass plate, and the mixture of AMIMCl and water was used as the coagulation bath. In the coagulation bath, the mass ratio of water to AMIM...

Embodiment 3

[0064]The raw material of agricultural waste is corn stalk, and its cellulose mass fraction is about 52%, and the raw material of cellulose is wood pulp, and its degree of polymerization is about 1300. Weigh 6.0g of dry BMIMAc ionic liquid and 0.64g of dry corn stalks, stir and dissolve at 120°C, and after about 120 minutes, a uniform brown solution is formed, which is black in the field of view observed with a polarizing microscope, indicating that corn stalk cellulose Almost completely dissolved. Weigh 3.2g of dry BMIMAc ionic liquid and 0.16g of dry wood pulp, stir and dissolve at 80°C, and after about 60 minutes, a uniform yellow transparent solution is formed, which is black in the field of view observed with a polarizing microscope, indicating that wood pulp The meal is basically completely dissolved. The above-mentioned corn stalk / BMIMAc solution and wood pulp / BMIMAc solution were mixed, and stirred at 80°C until uniformly mixed to obtain a corn stalk / wood pulp / BMIMAc ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com