Chromium-reducing cement and preparation method thereof

A technology for cement and cement clinker, applied in the field of cement, can solve the problems of strict temperature requirements and affect the effect of reducing chromium, and achieve the effects of strong oxidation resistance, avoiding the phenomenon of pump blockage, and good effect of reducing chromium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

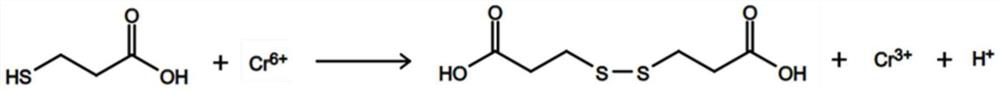

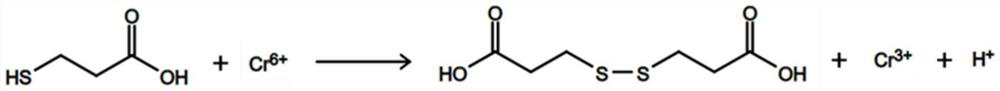

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Preparation of reduced chromium cement:

[0063] 1.1 Raw materials:

[0064] 85 parts of cement clinker, 10 parts of cement mixture, 5 parts of gypsum;

[0065] The grinding aid is a single-type chromium-reduced cement grinding aid, and its addition amount is 0.05% of the total weight of the main material;

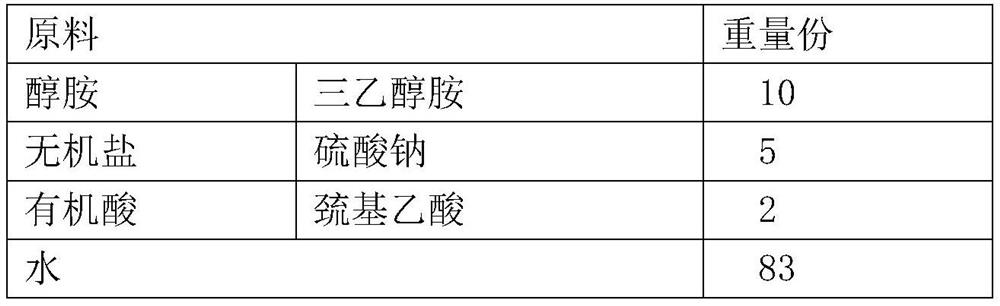

[0066] Grinding aid raw material consumption is shown in table 1 below:

[0067] Table 1 Embodiment 1 grinding aid raw material list:

[0068]

[0069] 1.2 Preparation method, comprising the following steps:

[0070] (1) preparation of grinding aids

[0071] ①At room temperature, add water into the reaction vessel, add inorganic salt or chromium-reducing additive and stir evenly while stirring; after adding inorganic salt or chromium-reducing additive, stir at a speed of 65r / min for 15min;

[0072] ②Stop stirring, add alcohol amine and stir evenly; after adding alcohol amine, stir at a speed of 65r / min for 4min.

[0073] ③Stop stirring, add organic acid and...

Embodiment 2

[0078] Preparation of reduced chromium cement:

[0079] 2.1 Raw materials:

[0080] 60 parts of cement clinker, 35 parts of cement mixture, 5 parts of gypsum;

[0081] The grinding aid is a single-type chromium-reduced cement grinding aid, and its addition amount is 0.2% of the total weight of the main material;

[0082] Grinding aid raw material consumption is shown in table 2 below:

[0083] Table 2 embodiment 2 grinding aid raw material list:

[0084]

[0085] 2.2 Preparation method, comprising the following steps:

[0086] (1) preparation of grinding aids

[0087] ①At room temperature, add water to the reaction vessel, add inorganic salt or chromium-reducing additive and stir evenly while stirring; after adding inorganic salt or chromium-reducing additive, stir for 5 minutes at a speed of 70r / min;

[0088] ②Stop stirring, add alcohol amine and stir evenly; after adding alcohol amine, stir at a speed of 70r / min for 3 minutes.

[0089] ③Stop stirring, add organic ac...

Embodiment 3

[0094] Preparation of reduced chromium cement:

[0095] 3.1 Raw materials:

[0096] 64.5 parts of cement clinker, 30 parts of cement mixture, and 5 parts of gypsum;

[0097] The grinding aid is a single-type chromium-reduced cement grinding aid, and its addition amount is 0.1% of the total weight of the main material;

[0098] Grinding aid raw material consumption is shown in table 3 below:

[0099] Table 3 embodiment 3 grinding aid raw material list:

[0100]

[0101] 3.2 Preparation method, comprising the following steps:

[0102] (1) preparation of grinding aids

[0103] ①At room temperature, add water into the reaction vessel, add inorganic salt or chromium-reducing additive and stir evenly while stirring; after adding inorganic salt or chromium-reducing additive, stir at a speed of 60r / min for 20min;

[0104] ②Stop stirring, add alcohol amine and stir evenly; after adding alcohol amine, stir at a speed of 60r / min for 5min.

[0105] ③Stop stirring, add organic aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com