Ceria-carbon-sulfur composite, method for preparing same, and positive electrode and lithium-sulfur battery comprising same

A cerium dioxide and carbon composite technology, applied in the direction of cerium oxide/cerium hydroxide, lanthanide oxide/hydroxide, rare earth metal oxide/hydroxide, etc. Performance of electrochemical properties and other issues to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0165] Water is prepared by mixing an aqueous dispersion of multi-walled carbon nanotubes (MWCNT, diameter: 10nm-20nm) and polystyrene (PS, diameter: 500nm-600nm) colloidal solution at a ratio of MWCNT:PS=1g:3.5g Dispersions.

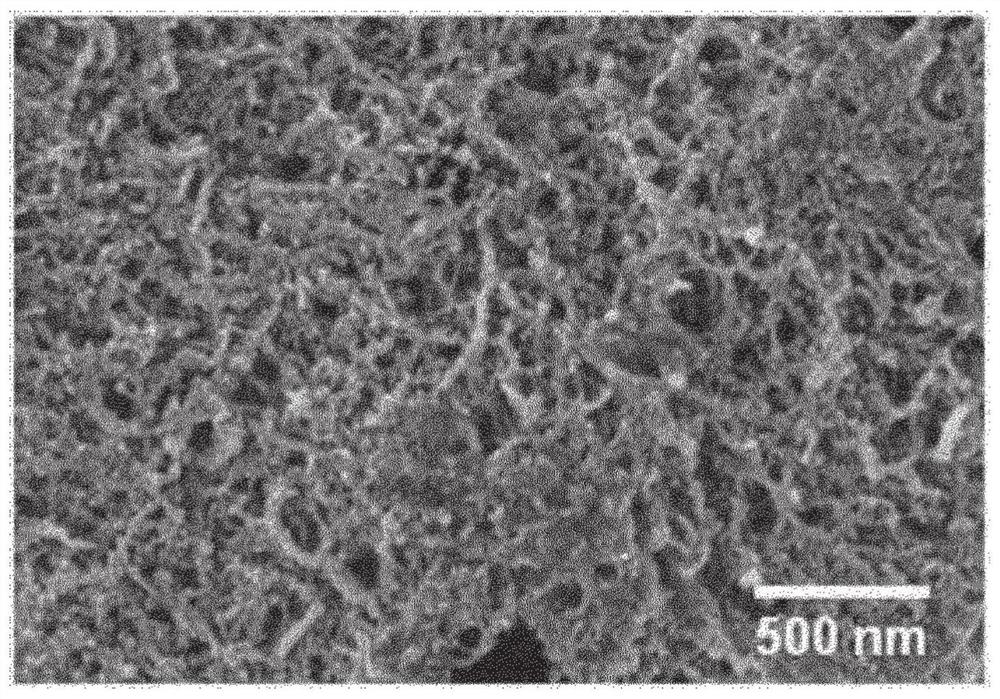

[0166] Polystyrene-carbon nanotube (PS-MWCNT) composites were prepared by spray-drying the dispersion at 140° C. (Labplant, SD-Basic). PS-MWCNT composites were recovered, followed by heat treatment at 500 °C for 2 h in an argon (Ar) atmosphere to remove polystyrene to fabricate CNT aggregates with hierarchical pore structures ( figure 2 ).

[0167] 0.45 g of the obtained carbon nanotube aggregates and 0.9 g of Ce(NO 3 ) 3 ·6H 2 O was added to distilled water and heated to a temperature of 95°C. While maintaining the above temperature, 1.75 g of 6-aminocaproic acid and 0.07 mL of hydrochloric acid were added and hydrothermal synthesis was performed for 5 hours.

[0168] After the synthesis was completed, the mixture was washed several times with d...

Embodiment 2

[0178] The mixture obtained by mixing the ceria-carbon-sulfur compound prepared in Example 1, the conductive material and the binder in a weight ratio of 8:1:1 was dissolved in distilled water to prepare the positive electrode active material slurry, and then This was coated on a current collector having an aluminum foil with a thickness of 20 μm to prepare a positive electrode.

[0179] Carboxymethylcellulose (CMC) was used as the conductive material, and styrene-butadiene rubber (SBR) was used as the binder.

[0180] A lithium-sulfur battery coin-type battery was fabricated using polyethylene as a separator and a lithium foil having a thickness of 45 μm as a negative electrode. At this point, use a mixture of 1M LiFSI and 0.5M LiNO 3 An electrolytic solution prepared by dissolving in a mixed solvent of diglyme and 1,3-dioxolane (volume ratio: 1:1) was used to prepare a coin-type battery.

experiment example 1

[0183] Experimental example 1: Electrochemical characteristics of lithium-sulfur batteries

[0184] The electrochemical performances of the lithium-sulfur batteries prepared in Example 2 and Comparative Example 2 were characterized.

[0185] Capacity characteristics and Coulombic efficiency were measured at a charge / discharge voltage range of 1.5V to 2.8V, a discharge C rate of 1C, and a charge C rate of 1C, and the results are shown in Table 1 and Figure 9 middle.

[0186] Table 1

[0187]

[0188] From the results in Table 1, it was confirmed that the lithium-sulfur battery of Example 2 including the ceria-carbon-sulfur complex of Example 1 of the present invention maintained the initial capacity to some extent even after 50 cycles. However, the lithium-sulfur battery of Comparative Example 2 containing the ceria-carbon-sulfur composite of Comparative Example 1 showed a decrease in capacity of about 40% or more after 50 cycles.

[0189] Therefore, it was confirmed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com