A glass handling device

A handling device and glass technology, applied in the direction of transportation and packaging, furnace, electric charge control, etc., can solve the problems of affecting work efficiency, not stable enough, glass breakage, etc., and achieve the effect of convenient operation, stable transportation, and reduction of glass breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

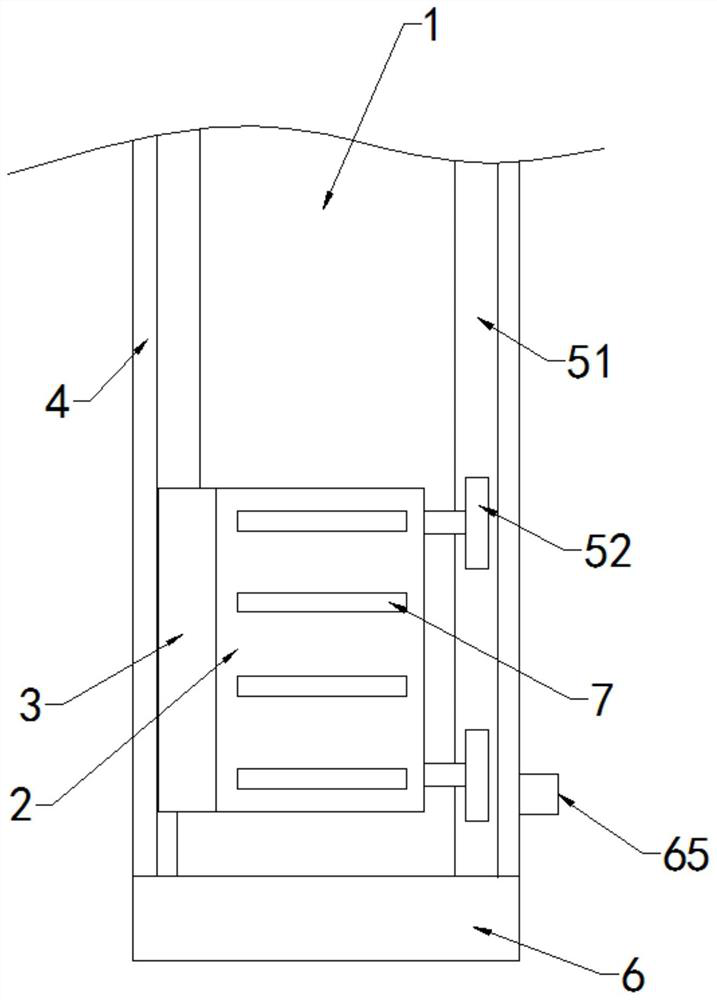

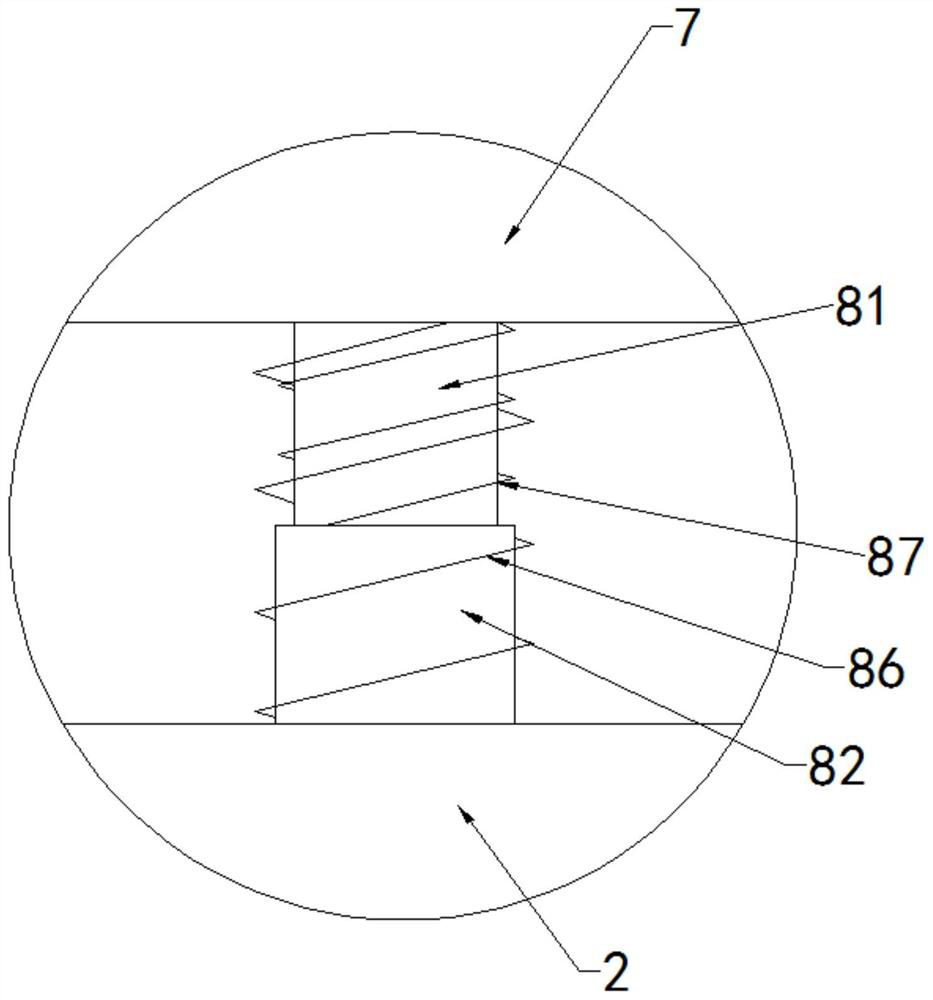

[0031] like Figure 1 to Figure 6As shown, the present invention discloses a glass handling device. In a specific embodiment of the present invention, it includes a base 1 fixed on the ground, and the base 1 is provided with a conveying mechanism that can move on the base 1 . The conveying mechanism includes a carrier plate 2 for carrying glass and a backing plate 3 vertically arranged on one side of the carrier plate 2, a limiting plate 4 is fixed on the side of the backing plate 3 away from the carrier plate 2 on the base 1, the The limit block 41 is fixed on the back plate 3, and the limit plate 4 is provided with a limit chute 42 for the limit block 41 to slide therein. The limit chute 42 is a T-shaped groove to prevent the limit Block 41 escapes from the limit chute 42, and the backing plate 3 is connected with the limit plate 4 through the limit block 41, and the end of the back plate 3 away from the limit plate 4 is fixed with a sponge protective layer 31; The board 2 ...

Embodiment 2

[0042] like Figure 7 and Figure 8 As shown, the difference between this embodiment and the above-mentioned embodiments is that: in this embodiment, the backing plate 3 is also provided with an adsorption mechanism, and the adsorption mechanism includes a Several suction cups 9 and the suction fan 11 and the suction pipe 10 installed on the back plate 3 away from the end of the suction cup 9, the suction cups 9 are evenly arranged on the back plate 3, and the back plate 3 is correspondingly provided with each suction cup 9 The air suction port 12 communicated, the air suction pipe 10 communicates with the air suction fan 11 , and the air suction pipe 10 communicates with the air suction port 12 .

[0043] In this embodiment, the suction cup 9 includes a connecting base 91, an inner disc body 92 and an outer disc body 93, the connecting base 91 is fixed on the backing plate 3, the outer disc body 93 is fixed on the connecting base 91, the inner disc The body 92 is fixed at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com