Smelting method of high cleanliness steel

A technology with high cleanliness and smelting method, which is applied in the field of iron and steel smelting, can solve the problems of high-end steel relying on imports and difficulties in the cleanliness of molten steel, and achieve the effects of low alloy cost, low cost, and prevention of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 adopts the method of the present invention to smelt high-cleanliness steel

[0038] The specific operation steps are as follows:

[0039] When tapping 1 / 4 of the converter, add aluminum-iron and silicon-manganese to the ladle to deoxidize the molten steel. After deoxidation, the oxygen is controlled at 0.02%. After tapping, the molten steel is stirred by weak argon blowing. The argon blowing time is 10 minutes to ensure that the deoxidized inclusions fully float up.

[0040] After the molten steel reaches the LF process, the aluminum wire is fed into the molten steel to deoxidize the molten steel so that the oxygen activity in the steel is 10×10 -4 %, heat the molten steel for 5 minutes to dissolve slag, add ferrosilicon to alloy the molten steel, blow argon and stir for 3 minutes, and then add ferromanganese to alloy the molten steel.

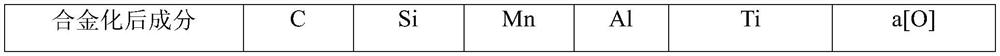

[0041] The components after converter tapping and LF process alloying are shown in Table 2:

[0042] Table 2 Steel com...

Embodiment 2

[0046] Embodiment 2 adopts the method of the present invention to smelt high-cleanliness steel

[0047] The specific operation steps are as follows:

[0048] When tapping 1 / 3 of the converter, add silicon calcium barium to the ladle to deoxidize the molten steel. After deoxidation, the oxygen is controlled at 0.03%. The time is 4 minutes to ensure that the inclusions after deoxidation fully float up.

[0049] After the molten steel reaches the LF process, add aluminum pellets to the molten steel and heat the molten steel to slag and deoxidize alloying for 5 minutes, and then measure the oxygen activity of the molten steel to 20×10 -4 %, then add silico-manganese to alloy the molten steel, blow argon and stir for 5 minutes, and then add metal manganese to alloy the molten steel.

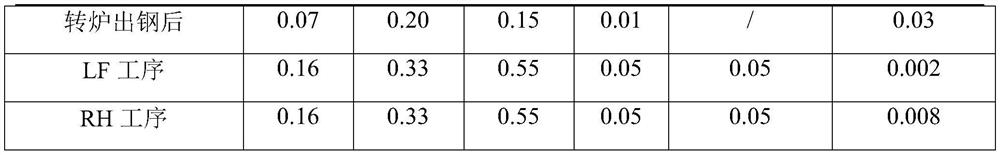

[0050] The components after converter tapping and LF process alloying are shown in Table 3:

[0051] Table 3 Steel composition / %

[0052]

[0053]

[0054] When the molten steel reaches the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com