Nano-modified sodium acetate trihydrate phase change heat storage material and preparation method thereof

A phase-change heat storage material, sodium acetate trihydrate technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of high price of hydroxylated graphene, increase of equipment production cost, and failure to solve phase separation, etc. Achieve the effects of increasing heat conduction efficiency, improving thermal conductivity, and improving heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

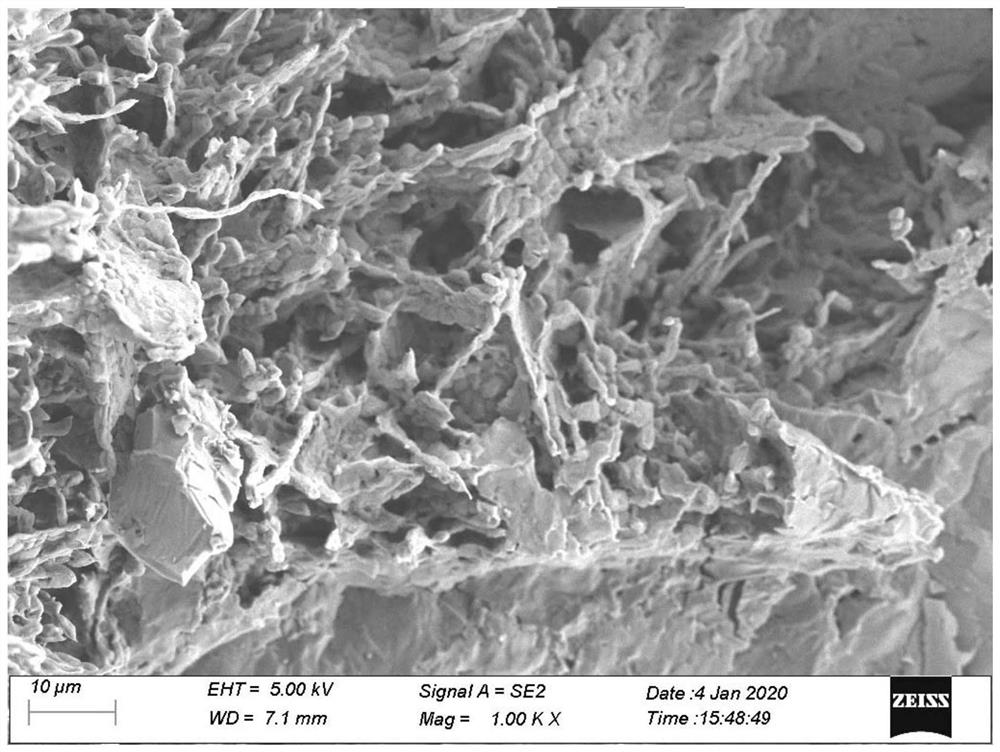

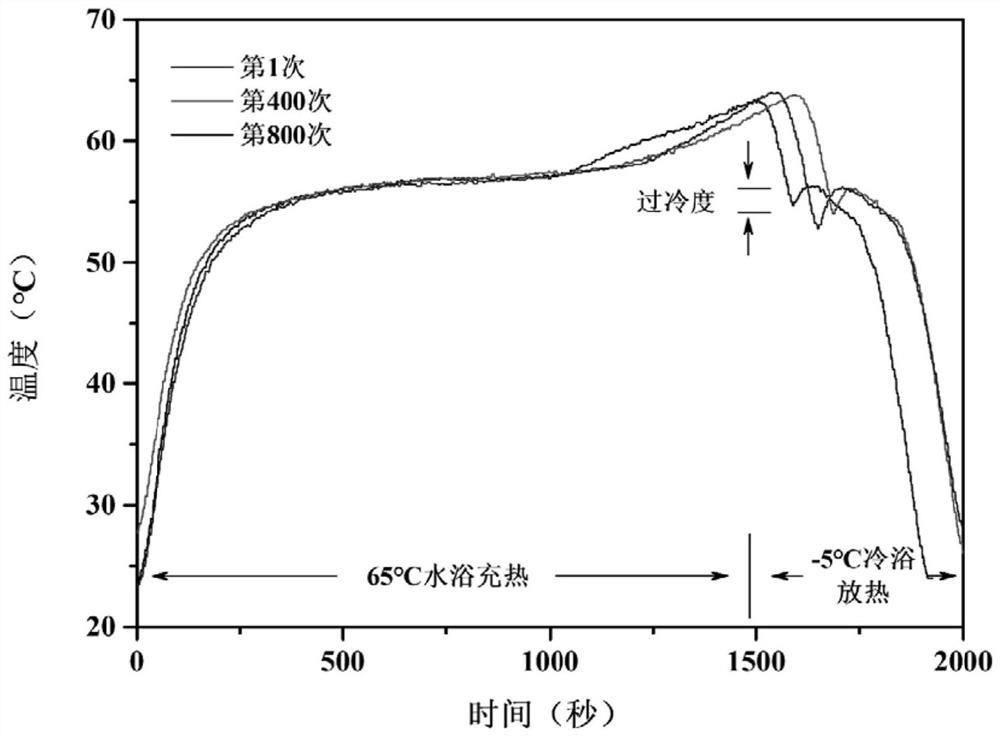

[0041] A nano-modified sodium acetate trihydrate phase change heat storage material, the preparation method is:

[0042] (1) Weigh 95g of sodium acetate trihydrate;

[0043] (2) Cellulose 2g;

[0044] (3) Nano silicon carbide (45nm) 0.5g;

[0045] (4) Graphite 10g;

[0046] (5) Put the above four materials together in a zirconia ball milling tank, the grinding ball is zirconia ball, the ball-to-material ratio is 20:1; the ball milling speed is 200rpm, and the ball milling time is 1 hour;

[0047] (6) Put the mixture into a stainless steel flat-bottomed test tube, place the test tube in a 65°C constant temperature water bath until it becomes a uniform black paste-like liquid. After cooling to room temperature in a cold bath, the nano-silicon carbide modified three is obtained. Water sodium acetate phase change heat storage material.

Embodiment 2

[0049] As described in Example 1, the difference is that the sodium acetate trihydrate in step (1) is 90 g and 99 g, respectively.

Embodiment 3

[0051] As described in Example 1, the difference is that the cellulose in step (2) is 0.5 g, 1 g, and 1.5 g, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com