A high stress corrosion resistance aluminum-copper-lithium alloy material

A lithium alloy, high stress technology, applied in the field of new materials and aerospace alloys, can solve the problems of reducing, restricting development, application and promotion, and achieve the effect of reasonable ratio and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Its preparation method comprises the following steps:

[0056] Ingredients: ingredients are made according to the composition of the aluminum alloy wire material;

[0057] Melting the prepared materials, casting them into molds and cooling to obtain ingots;

[0058] The ingot is cold-rolled into a plate, and after the cold rolling, the material is pre-stretched, annealed, solutionized, and aging heat treated to obtain a high-stress corrosion-resistant aluminum-copper-lithium alloy material; wherein,

[0059] The annealing procedures are sequentially 480-500°C / 10-12min, 360-380°C / 60-70min, 160-180°C / 100-120min and 300-320°C / 60-80min.

[0060] In some examples, the solid solution treatment is carried out at 530-550° C. for 60-80 minutes.

[0061] In some examples, the aging treatment is at 170-175° C. for 30-32 hours.

[0062] In some examples, the content ratio of Cu, Li and Zr is M(Cu):M(Li):M(Zr)=(8-11):(3-5):(1-2).

[0063] In some examples, M(Cu):M(Li):M(Zr)=10:5...

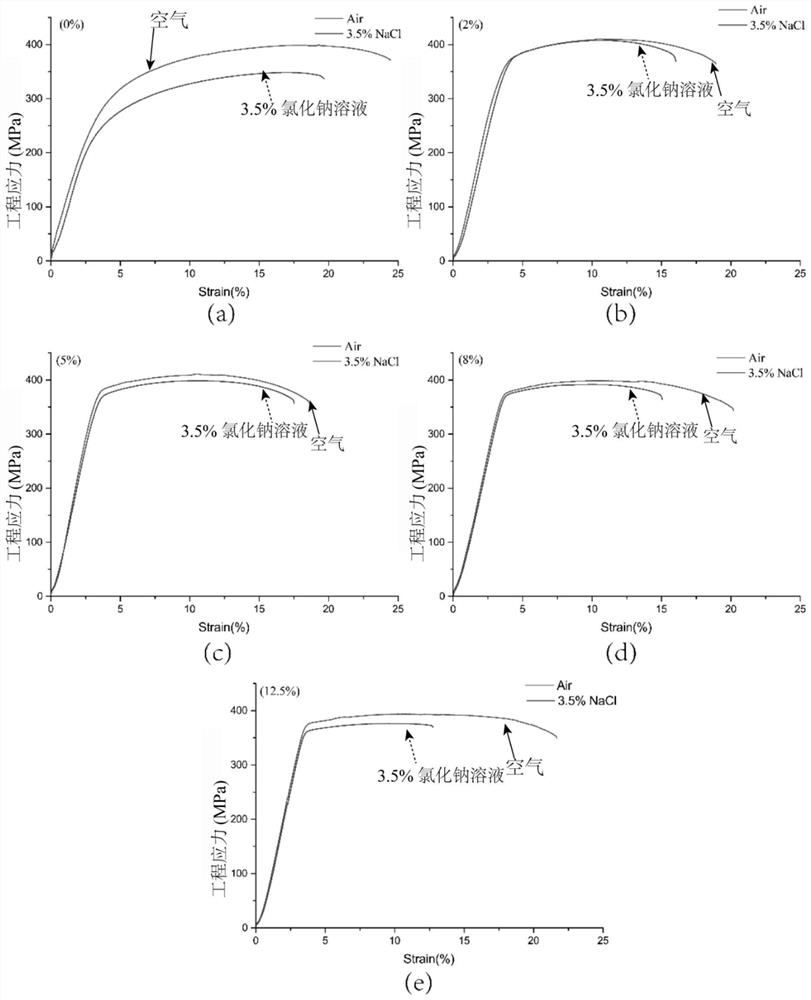

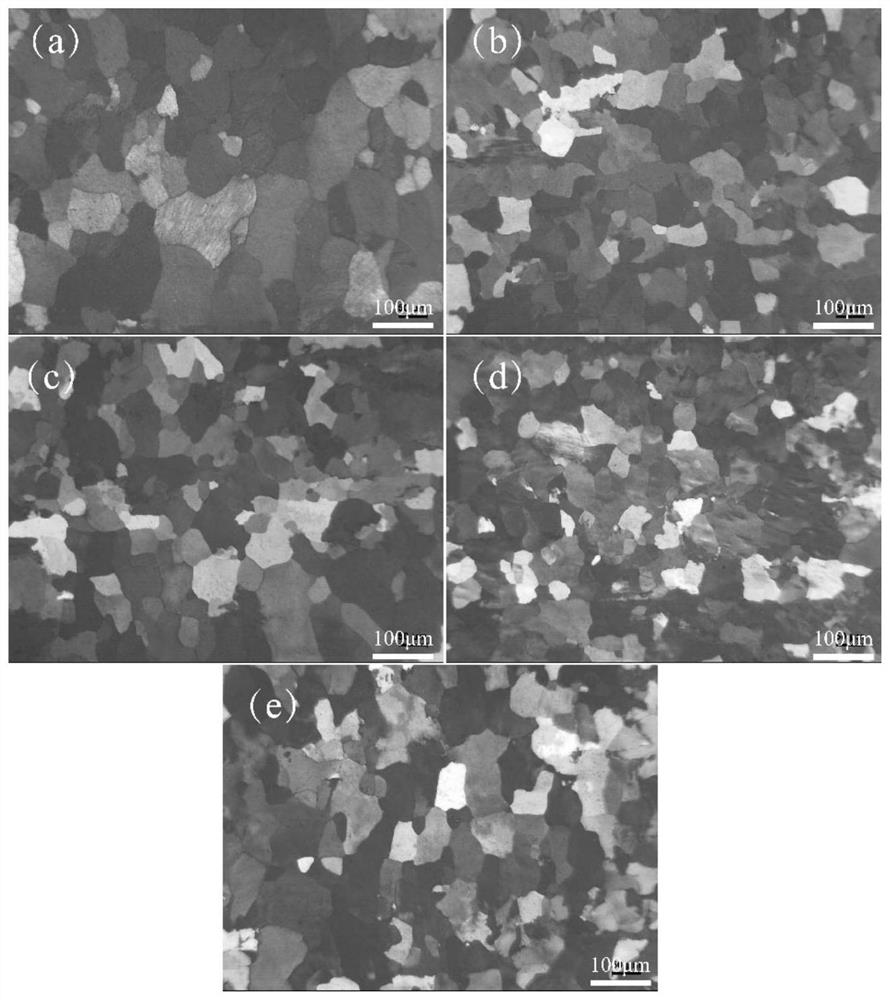

Embodiment 1

[0080] 1) Take Cu: 2.8wt.%, Li: 1.4wt.%, Zr: 0.28 wt.%, and the balance is Al according to the weight percentage of the constituent elements;

[0081] 2) The above materials are smelted at a high temperature in a smelting furnace at a temperature of 750°C until they are melted, then the alloy melt is poured into a mold and stirred, and cooled to obtain an ingot;

[0082] 3) The ingot is cold rolled from 6.5mm to 3.0mm, and the plate is pre-stretched after cold rolling, and the deformation is 4.5%;

[0083] 4) Annealing treatment (480°C / 10min)+(360°C / 65min)+(160°C / 100min+300°C / 60min), followed by solid solution 530°C / 60min and artificial peak aging treatment 170°C / 30h .

Embodiment 2

[0085] 1) Take Cu: 2.83wt.%, Li: 1.45wt.%, Zr: 0.30 wt.%, and the balance is Al according to the weight percentage of the constituent elements;

[0086] 2) The above materials are smelted at a high temperature in a smelting furnace at a temperature of 755°C until they are melted, then the alloy melt is poured into a mold and stirred, and cooled to obtain an ingot;

[0087] 3) The ingot is cold rolled from 6.5mm to 3.5mm, and the plate is pre-stretched after cold rolling, and the deformation is 10.0%;

[0088] 4) Annealing treatment (490°C / 11min)+(380°C / 70min)+(170°C / 110min+310°C / 60min), followed by solid solution 550°C / 60min and artificial peak aging treatment 175°C / 31h .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com