A method for semi-continuous casting of high-purity aluminum ingots using a fine-grain crystallizer

A mold, semi-continuous technology, applied in the field of non-ferrous metal casting, can solve the problems of affecting the purity of high-purity aluminum ingots, high energy consumption, and high casting costs, and achieve fine structure, avoid wide range, and total axis. height shortening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is a method for semi-continuously casting high-purity aluminum ingots using a fine-grain crystallizer. The high-purity aluminum ingots obtained by the present invention can be used as anode foils for electrolytic capacitors, lead wires for capacitors, and integrated circuits. Wires, base materials for vacuum evaporators, stable conductors for superconductors, base materials for disk alloys and aluminum alloys with high fracture toughness, etc., are widely used.

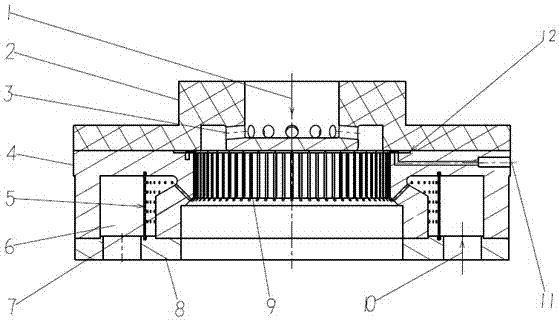

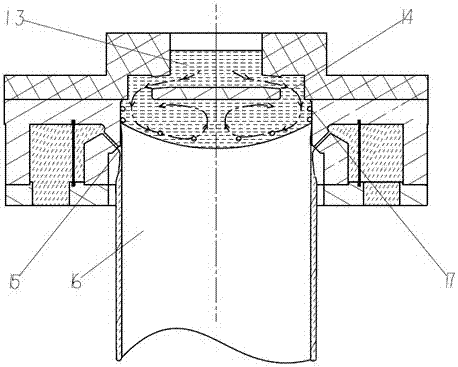

[0027] In the method of the present invention, a fine-grain crystallizer is used, and the high-purity aluminum ingot is either a round ingot, a flat ingot, or a square ingot. The design size of the round ingot is ΦD, and the design size of the flat ingot is D×d, D>d, the design size of the square ingot is D×D, the structure of the fine-grain crystallizer used in the round ingot, the flat ingot and the square ingot is different, but the fine-grain crystallization All contain shunt cover 2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com