Heat treatment method for structure refinement of high-strength automobile steel

A heat treatment method and technology of heat treatment furnace, applied in the direction of heat treatment furnace, heat treatment equipment, furnace type, etc., can solve the problems of high equipment requirements, refinement, large equipment investment, etc., and achieve the effect of good effect, easy operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

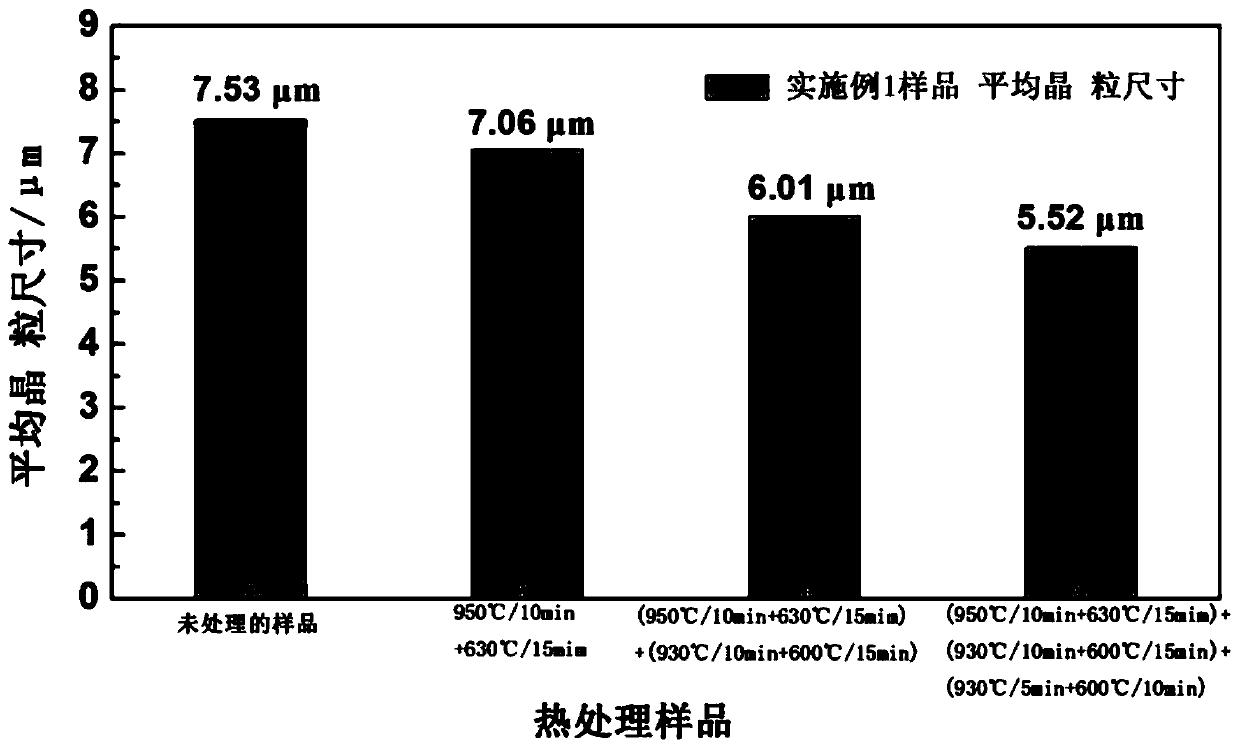

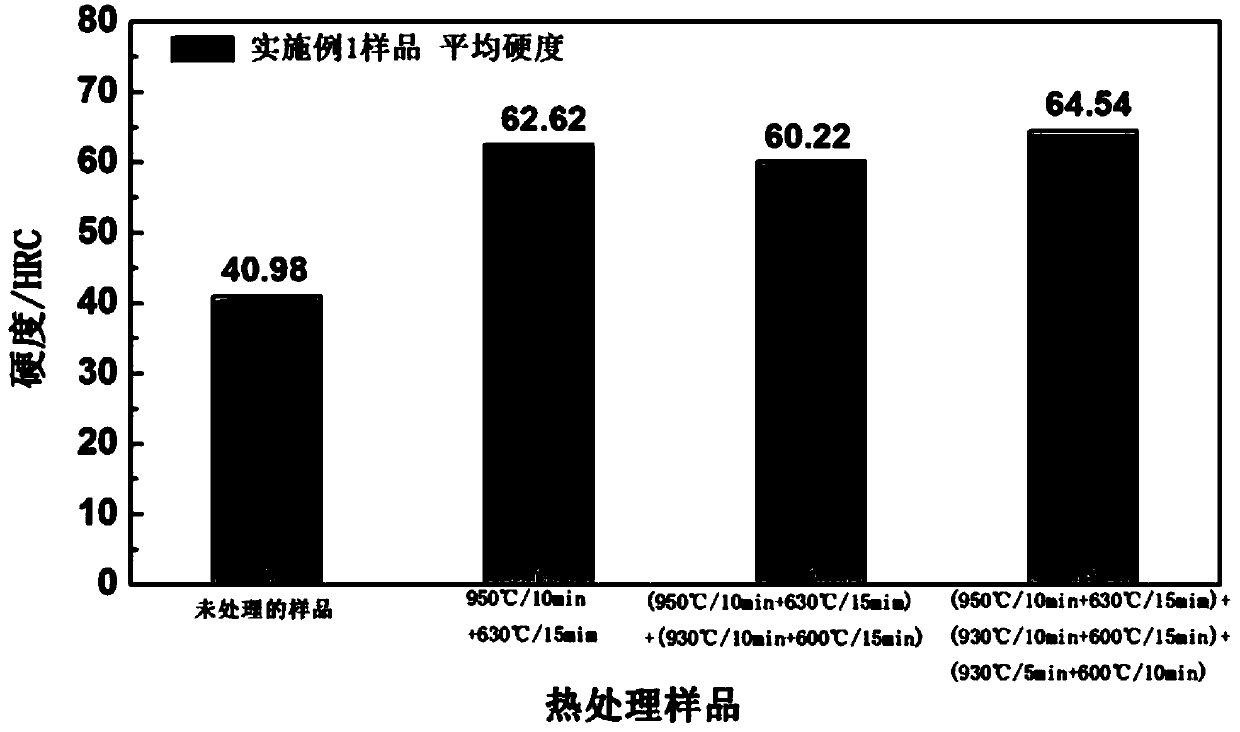

Embodiment 1

[0028] High-strength automobile C-Mn-Cr steel plate sample (main component (mass percentage); C; 0.21%, Mn; 1.69%, Cr; 1.30%, Si; 0.04%, Ti; 0.002%, Nb; 0.009%, Fe; Surplus) whose size is 130mm * 30mm * 4mm (length * width * thickness), the heat treatment method of high-strength automobile steel structure refinement described in the present invention carries out the following steps of heat treatment successively in a heat treatment furnace;

[0029] S1, quenching treatment; the heating temperature is 950°C, the heating rate is 10°C / s, the holding time is 10min, the cooling method of quenching treatment is water cooling, and the cooling rate is about 20°C / s~25°C / s;

[0030] S2, tempering treatment; the tempering temperature is 630°C, the heating rate is 5°C / s, the holding time is 15min, the cooling method of tempering treatment is air cooling, and the cooling rate is about 5°C / s~8°C / s;

[0031] S3, quenching treatment; the heating temperature is 930°C, the heating rate is 10°C / ...

Embodiment 2

[0041] High-strength automobile C-Mn-Cr steel plate sample (main component (mass percentage); C; 0.27%, Mn; 2.03%, Cr; 1.50%, Si; 0.12%, Ti; 0.003%, Nb; 0.011%, Fe; Surplus) whose size is 130mm * 30mm * 4mm (length * width * thickness), the heat treatment method of high-strength automobile steel structure refinement described in the present invention carries out the following steps of heat treatment successively in a heat treatment furnace;

[0042] S1, quenching treatment; the heating temperature is 950°C, the heating rate is 10°C / s, the holding time is 10min, the cooling method of quenching treatment is water cooling, and the cooling rate is about 20°C / s~25°C / s;

[0043] S2, tempering treatment; the tempering temperature is 630°C, the heating rate is 5°C / s, the holding time is 15min, the cooling method of tempering treatment is air cooling, and the cooling rate is about 5°C / s~8°C / s;

[0044] S3, quenching treatment; the heating temperature is 940°C, the heating rate is 10°C / ...

Embodiment 3

[0053] High-strength automobile C-Mn-Cr steel plate sample (main component (mass percentage); C; 0.21%, Mn; 1.66%, Cr; 1.21%, Si; 0.05%, Ti; 0.01%, Nb; 0.034%, Fe; Surplus) whose size is 130mm * 30mm * 4mm (length * width * thickness), the heat treatment method of high-strength automobile steel structure refinement described in the present invention carries out the following steps of heat treatment successively in a heat treatment furnace;

[0054] S1, quenching treatment; the heating temperature is 940°C, the heating rate is 10°C / s, the holding time is 10min, the cooling method of quenching treatment is water cooling, and the cooling rate is about 20°C / s~25°C / s;

[0055] S2, tempering treatment; the tempering temperature is 620°C, the heating rate is 5°C / s, the holding time is 15min, the cooling method of tempering treatment is air cooling, and the cooling rate is about 5°C / s~8°C / s;

[0056] S3, quenching treatment; the heating temperature is 930°C, the heating rate is 10°C / s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com