Oil and gas field gathering and transportation pipeline corrosion inhibitor capable of resisting corrosion of high-calcium produced water

A technology for gathering and transporting pipelines and corrosion inhibitors, which is applied in the direction of earthwork drilling, drilling compositions, wellbore/well components, etc. Development and application issues, to achieve the effect of good corrosion inhibition, stable structure, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the anti-high-calcium produced water corrosion inhibitor of the present invention is as follows: in terms of mass percentage, 70-95% of the large-molecular imidazole-based ionic liquid and 5-30% of the small-molecular imidazole-based ionic liquid are evenly mixed. .

[0044] The measuring method of corrosion inhibitor corrosion rate in each embodiment among the present invention is:

[0045] Medium composition: CaCl 2 : 100g / L, CO 2 Partial pressure 0.5MPa, total pressure 5MPa;

[0046] Test temperature: 50°C;

[0047] Test time: 96 hours;

[0048] Test material: L245 steel.

[0049] First polish the L245 steel, then wash it with petroleum ether, acetone and ethanol, dry it, weigh it, put the prepared solution in the reaction vessel with a reflux device, add 100ppm of the prepared corrosion inhibitor, stir evenly, and weigh it. The heavy L245 steel was hung into the reaction vessel, and the temperature was raised to 50°C. After stabilizin...

Embodiment 1

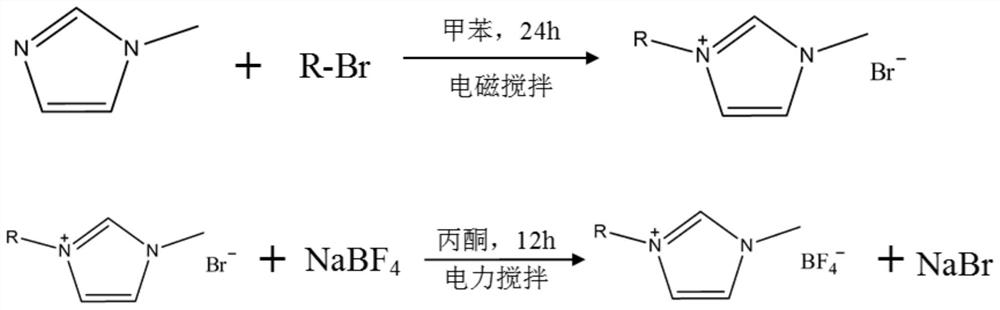

[0051] The macromolecular ionic liquid was prepared by the following process: Add 25mmol N-methylimidazole and 45mmol toluene into a three-necked flask equipped with a condenser and a dropping funnel, stir evenly with electromagnetic, heat to 85°C, and use a speed of 15mL / min 27.5 mmol of 1-bromododecane was added dropwise, and after reacting for 23 hours, the solution was evaporated to remove the solvent to obtain a yellow viscous liquid. The above liquid was mixed with 27.5mmol of NaBF 4 Add 50 mmol of acetone into a single-necked round-bottomed flask with a condensing reflux device, react with a magnetic stirrer at a speed of 180 rpm for 11 hours at room temperature, and then filter to remove the white precipitate NaBr. Add an appropriate amount of dichloromethane to the filtrate to form a white precipitate , filtered, acetone and dichloromethane were removed by rotary evaporation, and vacuum-dried at 40°C for 23 hours to obtain 3-dodecyl-1-methylimidazolium tetrafluorobora...

Embodiment 2

[0055] The macromolecular ionic liquid was prepared by the following process: add 25mmol N-methylimidazole and 45mmol toluene into a three-necked flask equipped with a condenser tube and a dropping funnel, stir evenly with electromagnetic, heat to 85°C, and add dropwise at 15mL / min 27.5 mmol of 1-bromohexadecane was reacted for 23 hours, and the solution was evaporated to remove the solvent to obtain a yellow viscous liquid. The above liquid was mixed with 27.5mmol NaPF 6 And 50mmol of acetone was added to a single-necked round bottom flask with a condensing reflux device, magnetically stirred at room temperature and reacted at a speed of 180 rpm for 11h, then filtered to remove the white precipitate NaBr, and 20mL of dichloromethane was added to the filtrate to form a white precipitate, and filtered , Rotary evaporation for 3h to separate acetone and dichloromethane, 40 ° C vacuum drying to obtain 3-hexadecyl-1-methylimidazolium hexafluorophosphate.

[0056] The small molecu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com