Preparation method of special grease for fried noodle ball production

A technology of meatballs and oil, which is applied in the field of edible oil, can solve the problems of poor separation of blended oil, oil, and oil residue, insufficient frying resistance, and high cost, and achieve enhanced frying stability and gelatinization. The effect of controlling and preventing rancidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

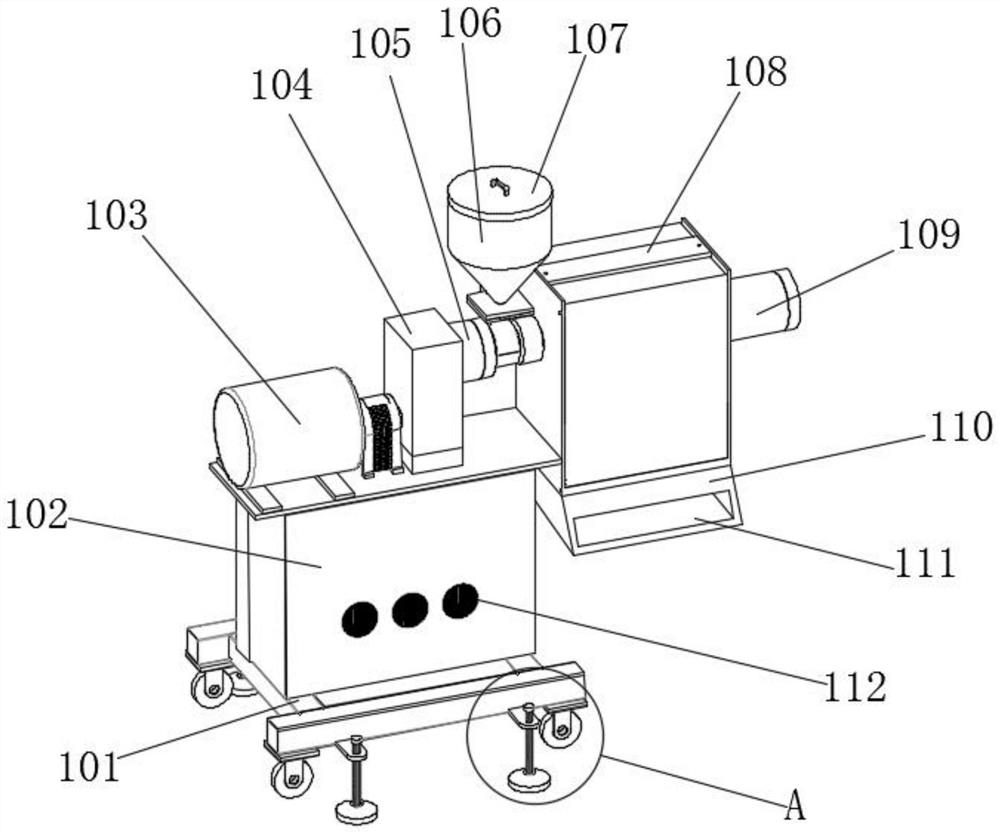

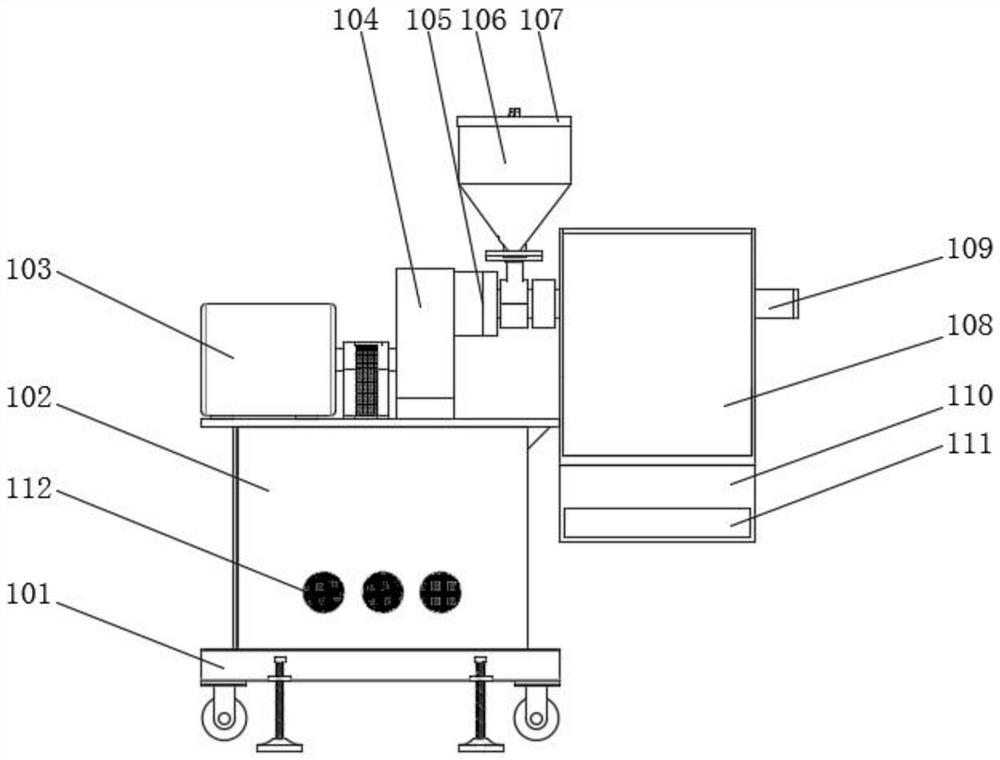

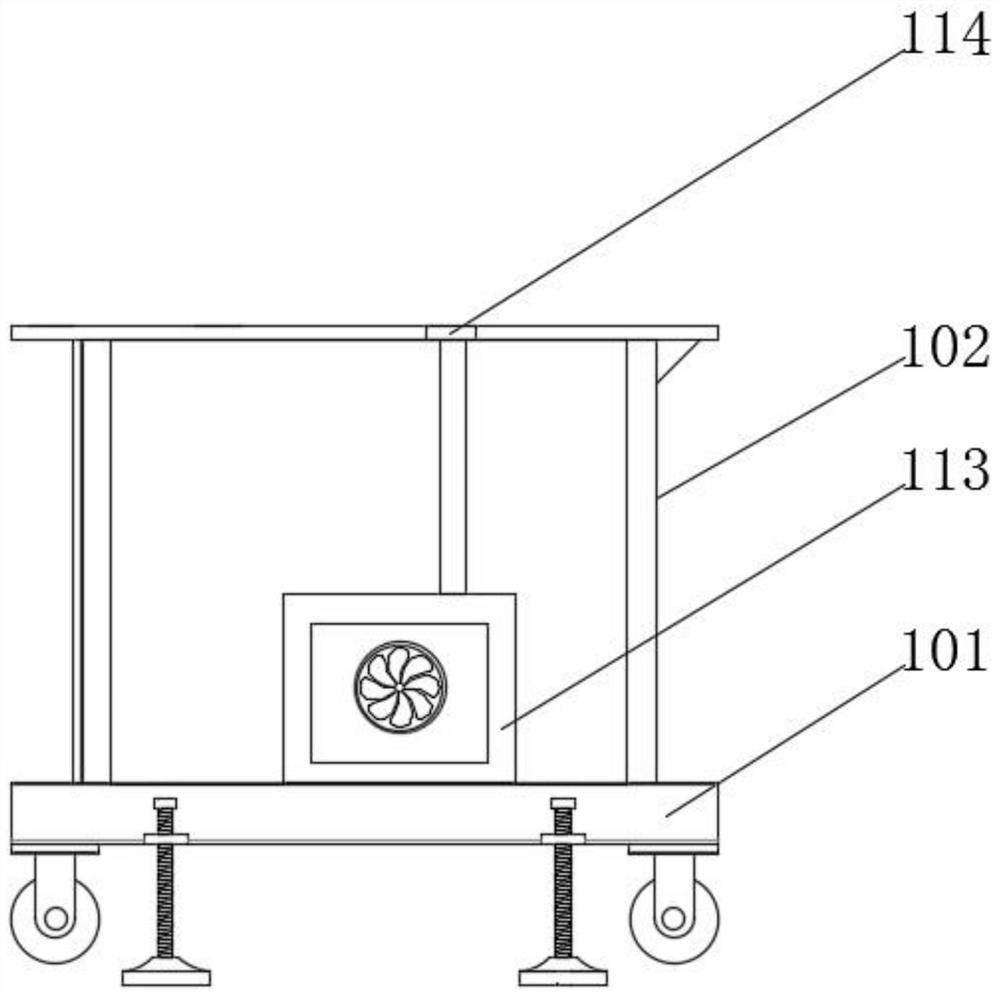

[0046] see Figure 1-6 Shown, the present embodiment is a kind of preparation method for the special grease that is used for the production of ramen balls, and this special grease that is used for the production of ramen balls is prepared by following components by weight:

[0047] 60 parts of sunflower seed blended oil, 0.5.0 parts of soybean protein isolate, 0.1.3 parts of tea polyphenols, 0.3.9 parts of pectin, and 27 parts of deionized water;

[0048] Sunflower seed blending oil comprises the following components by weight percentage:

[0049] 40 parts of sunflower oil, 20 parts of palm oil, 15 parts of rapeseed oil, 4 parts of sesame oil, 0.01.02 parts of rosemary extract, 0.04.05 parts of ascorbyl palmitate;

[0050] The special grease for the production of ramen meatballs is prepared by the following steps:

[0051] Step 1: Wash the palm fruit, sunflower seeds, sesame and rapeseed separately and dry them at room temperature;

[0052] Step 2: Evenly roast the dried pa...

Embodiment 2

[0066] see Figure 1-6 Shown, the present embodiment is a kind of preparation method for the special grease that is used for the production of ramen balls, and this special grease that is used for the production of ramen balls is prepared by following components by weight:

[0067] 65 parts of sunflower seed blended oil, 1.2 parts of soybean protein isolate, 0.2 parts of tea polyphenols, 0.6 parts of pectin, and 33 parts of deionized water;

[0068] Sunflower seed blending oil comprises the following components by weight percentage:

[0069] 47 parts of sunflower oil, 25 parts of palm oil, 17 parts of rapeseed oil, 7 parts of sesame oil, 0.015 parts of rosemary extract, 0.045 parts of ascorbyl palmitate;

[0070] The special grease for the production of ramen meatballs is prepared by the following steps:

[0071] Step 1: Wash the palm fruit, sunflower seeds, sesame and rapeseed separately and dry them at room temperature;

[0072] Step 2: Evenly roast the dried palm fruit, ...

Embodiment 3

[0086] see Figure 1-6 Shown, the present embodiment is a kind of preparation method for the special grease that is used for the production of ramen balls, and this special grease that is used for the production of ramen balls is prepared by following components by weight:

[0087] 70 parts of sunflower seed blended oil, 0.2.0 parts of soybean protein isolate, 0.0.3 parts of tea polyphenols, 0.0.9 parts of pectin, and 39 parts of deionized water;

[0088] Sunflower seed blending oil comprises the following components by weight percentage:

[0089] 55 parts of sunflower oil, 30 parts of palm oil, 30 parts of rapeseed oil, 10 parts of sesame oil, 0.0.02 parts of rosemary extract, 0.0.05 parts of ascorbyl palmitate;

[0090] The special grease for the production of ramen meatballs is prepared by the following steps:

[0091] Step 1: Wash the palm fruit, sunflower seeds, sesame and rapeseed separately and dry them at room temperature;

[0092] Step 2: Evenly roast the dried pal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com