Technical method for repairing block falling defect of flap sliding rail chromium-plated surface through laser cladding

A technology of laser cladding and process method, applied in metal material coating process, coating and other directions, can solve the problems of chrome plating layer peeling, difficult to control the repair trajectory and repair area size and thickness, processing and grinding trouble, etc. Life extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

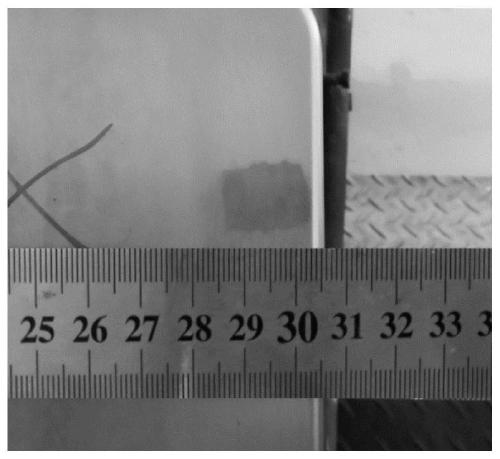

[0033] Laser cladding is used to repair the defect of Cr-plated sliding surface of a certain type of aircraft flap slide rail.

[0034] A certain type of aircraft flap rail is made of ultra-high-strength steel precision forged + chrome-plated on the surface. The material is 30CrMnSiNi2A steel. After the aircraft flies to a renovation cycle, the sliding working surface of the flap rail and the counterpart will appear worn out. For pits, the depth of the defect is 0.2-1.0mm, the size of the defect does not exceed 50mm, and the distribution of defects is irregular.

[0035] Preparation of special laser cladding materials for 30CrMnSiNi2A steel: medium frequency induction furnace is used to melt and prepare ultra-high strength steel ingots with carbon content less than 0.2%, nickel and cobalt content less than 20%, and impurity elements less than 0.0001%. The ultra-high-strength steel powder is prepared by the gas atomization pulverization process. The powder material with a parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com